Abstract

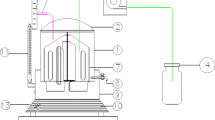

Biodiesel-processing factories employing the alkali-catalyzed transesterification process generate a large amount of wastewater containing high amount of methanol, glycerol, and oil. As such, wastewater has high potential to produce biogas using anaerobic treatment. The aim of this research was to investigate the performance of an anaerobic baffled reactor for organic removal and biogas production from biodiesel wastewater. The effect of different organic loading rates, varying from 0.5 kg m−3 d−1 to 3.0 kg m−3 d−1 of chemical oxygen demand, was determined using three 22 L reactors, each comprising five separate compartments. Wastewater was pretreated with chemical coagulants to partially remove oil prior to experimentation. Results show that the anaerobic baffled reactor operated at 1.5 kg m−3 d−1 of chemical oxygen demand and ten days of hydraulic retention time provided the best removal efficiencies of 99 % of chemical oxygen demand, 100 % of methanol, and 100 % of glycerol. Increasing the organic loading rate over 1.5 kg m−3 d−1 of chemical oxygen demand led to excessive accumulation of volatile fatty acids thereby making the pH drop to a value unfavorable for methanogenesis. The biogas production rate was 12 L d−1 and the methane composition accounted for 64–74 %. Phase-separated characteristics revealed that the highest chemical oxygen demand removal percentage was achieved in the first compartment and the removal efficiency gradually decreased longitudinally. A scanning electron microscopic study indicated that the most predominant group of microorganisms residing on the external surface of the granular sludge was Methanosarcina.

Similar content being viewed by others

References

Al-Shamrani, A. A., James, A., & Xiao, H. (2002). Destabilisation of oil-water emulsions and separation by dissolved air flotation. Water Research, 36, 1503–1512. DOI: 10.1016/S0043-1354(01)00347-5.

Barber, W. P., & Stuckey, D. C. (1999). The use of the anaerobic baffled reactor (ABR) for wastewater treatment: a review. Water Research, 33, 1559–1578. DOI: 10.1016/S0043-1354(98)00371-6.

Boopathy, R., & Tilche, A. (1991). Anaerobic digestion of high strength molasses wastewater using hybrid anaerobic baffled reactor. Water Research, 25, 785–790. DOI: 10.1016/0043-1354(91)90157-L.

Chavalparit, O., & Ongwandee, M. (2009). Optimizing electrocoagulation process for the treatment of biodiesel wastewater using response surface methodology. Journal of Environmental Sciences, 21, 1491–1496. DOI: 10.1016/S1001-0742(08)62445-6.

Department of Alternative Energy Development and Efficiency (2008). Biodiesel production in Thailand year 2007–2008. Bangkok, Thailand: Ministry of Energy of Thailand.

Eaton, A. D., Clesceri, L. S., & Greenberg, A. E. (1995). Standard methods for the examination of water and wastewater (19th ed.). Washington, DC, USA: American Public Health Association.

Faisal, M., & Unno, H. (2001). Kinetic analysis of palm oil mill wastewater treatment by a modified anaerobic baffled reactor. Biochemical Engineering Journal, 9, 25–31. DOI: 10.1016/S1369-703X(01)00122-X.

Ito, T., Nakashimada, Y., Senba, K., Matsui, T., & Nishio, N. (2005). Hydrogen and ethanol production from glycerolcontaining wastes discharged after biodiesel manufacturing process. Journal of Bioscience and Bioengineering, 100, 260–265. DOI: 10.1263/jbb.100.260.

Ji, G. D., Sun, T. H., Ni, J. R., & Tong, J. J. (2009). Anaerobic baffled reactor (ABR) for treating heavy oil produced water with high concentrations of salt and poor nutrient. Bioresource Technology, 100, 1108–1114. DOI: 10.1016/j.biortech.2008.08.015.

Kacprzak, A., Krzystek, L., & Ledakowicz, S. (2010). Codigestion of agricultural and industrial wastes. Chemical Papers, 64, 127–131. DOI: 10.2478/s11696-009-0108-5.

Kuşçu, Ö. S., & Sponza, D. T. (2005). Performance of anaerobic baffled reactor (ABR) treating synthetic wastewater containing p-nitrophenol. Enzyme and Microbial Technology, 36, 888–895. DOI: 10.1016/j.enzmictec.2005.01.001.

Ma, F., & Hanna, M. A. (1999). Biodiesel production: a review. Bioresource Technology, 70, 1–15. DOI: 10.1016/S0960-8524(99)00025-5.

Marchetti, J. M., Miguel, V. U., & Errazu, A. F. (2007). Possible methods for biodiesel production. Renewable and Sustainable Energy Reviews, 11, 1300–1311. DOI: 10.1016/j.rser.2005.08. 006.

Polprasert, C. (1996). Organic waste recycling, technology and management (2nd ed.). Chichester, UK: Wiley.

Raghareutai, T., Chavalparit, O., & Ongwandee, M. (2010). Development of environmental sustainability for the biodiesel industry in Thailand. International Journal of Sustainable Development & World Ecology, 17, 363–369. DOI: 10.1080/13504509.2010.502752.

Saatci, Y., Hasar, H., & Cici, M. (2001). Treatability of vegetable oil industry effluents through physical-chemical methods. Fresenius Environmental Bulletin, 10, 854–858.

Speece, R. E. (1996). Anaerobic biotechnology for industrial wastewaters. Nashville, TN, USA: Archae Press.

Suehara, K., Kawamoto, Y., Fujii, E., Kohda, J., & Yano, T. (2005). Biological treatment of wastewater discharged from biodiesel fuel production plant with alkali-catalyzed transesterification. Journal of Bioscience and Bioengineering, 100, 437–442. DOI: 10.1263/jbb.100.437.

Thoenes, P. (2006). Biofuel and commodity markets-palm oil focus. Rome, Italy: FAO, Commodities and Trade Division.

Wang, J., Huang, Y., & Zhao, X. (2004). Performance and characteristics of an anaerobic baffled reactor. Bioresource Technology, 93, 205–208. DOI: 10.1016/j.biortech.2003.06.004.

Zheng, D., Angenent, L. T., & Raskin, L. (2006). Monitoring granule formation in anaerobic upflow bioreactors using oligonucleotide hybridization probes. Biotechnology and Bioengineering, 94, 458–472. DOI: 10.1002/bit.20870.

Zhu, G.-F., Li, J.-Z., Wu, P., Jin, H.-Z., & Wang, Z. (2008). The performance and phase separated characteristics of an anaerobic baffled reactor treating soybean protein processing wastewater. Bioresource Technology, 99, 8027–8033. DOI: 10.1016/j.biortech.2008.03.046.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Phukingngam, D., Chavalparit, O., Somchai, D. et al. Anaerobic baffled reactor treatment of biodiesel-processing wastewater with high strength of methanol and glycerol: reactor performance and biogas production. Chem. Pap. 65, 644–651 (2011). https://doi.org/10.2478/s11696-011-0061-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.2478/s11696-011-0061-y