Abstract

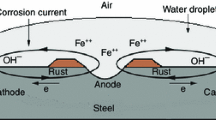

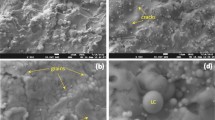

Ethylene chlorotrifluoroethylene (ECTFE) coating was applied to the surface of carbon steel through electrostatic spraying and low-temperature heat treatment. The morphology and structure of the coating were analyzed using various characterization techniques. The electrochemical data of the coated steel soaked in 3.5% (mass fraction) NaCl solution for 90 d at different periods were also examined. The findings indicate that the outer surface of the coating remains structurally stable before and after soaking. F can diffuse into the steel substrate, facilitating the bonding between the coating and the steel substrate, but the free F also induces a weakening effect on the crystalline structure. Due to the thickness of the coating edge and the susceptibility to infiltration of the corrosive medium, under-film micro-zone corrosion occurs at a slow rate. After soaking for 90 d, the impedance modulus measures approximately 104 Ω·cm2, and the open circuit potential (OCP) is −0.61 V. The self-corrosion current density is 1.13×10−6 A/cm2, resulting in a calculated coating protection rate of 99.29%. In summary, despite edge corrosion occurring, the ECTFE coating provides excellent corrosion protection.

摘要

目的

钢结构应用广泛, 但极易发生腐蚀。本研究旨在通过静电喷涂和低温热处理技术在碳钢表面制备乙烯-三氟氯乙烯(ECTFE)涂层, 并对涂层钢的腐蚀行为及耐蚀机理进行深入研究, 以揭示在ECTFE涂层保护下碳钢的界面腐蚀演变规律, 并为钢结构耐久性技术的提升以及防腐涂层材料的发展提供新的思路。

创新点

1. 将半结晶态的ECTFE涂层涂覆于碳钢表面, 可对钢结构进行良好的腐蚀防护;2. 涂层钢的边缘腐蚀行为会影响附着力, 但涂层的致密结构依然能够起到屏障作用。

方法

1. 采用静电喷涂结合低温热处理技术在碳钢表面制备ECTFE涂层;2. 通过热分析仪TG-DSC确定ECTFE的致密化成型温度, 并采用傅里叶变换红外光谱仪、X射线衍射、扫描电子显微镜和能谱仪表征ECTFE涂层钢在3.5%(质量分数)的NaCl溶液中浸泡90 d后前后涂层及界面的结构组成、形貌演变及元素分布, 同时测试不同浸泡时期涂层钢的开路电位(OCP)、电化学阻抗谱(EIS)和动电位扫描特性。

结论

1. 将ECTFE涂层在3.5%的NaCl溶液中浸泡90 d后, 其外表面结构稳固;2. F离子能扩散进入钢基体, 有助于涂层和钢基体的结合, 但会削弱涂层的晶态结构;3. 由于涂层边缘较薄, 腐蚀介质容易从边缘侵入, 造成边缘腐蚀;4. 涂层钢在边缘腐蚀的情况下, 由于涂层结构致密稳定, 所以其依然具有优异的阻隔效果。

Similar content being viewed by others

References

Abdel-Hady EE, El-Toony MM, 2015. Grafting of vinyl pyrrolidone/styrene onto ethylene/chlorotrifluoroethylene membrane for proton exchange membrane fuel cell. Electrochimica Acta, 176:472–479. https://doi.org/10.1016/j.electacta.2015.06.136

Alibakhshi E, Akbarian M, Ramezanzadeh M, et al., 2018. Evaluation of the corrosion protection performance of mild steel coated with hybrid sol-gel silane coating in 3.5 wt% NaCl solution. Progress in Organic Coatings, 123:190–200. https://doi.org/10.1016/j.porgcoat.2018.07.008

Cai GY, Xiao S, Deng CM, et al., 2021. CeO2 grafted carbon nanotube via polydopamine wrapping to enhance corrosion barrier of polyurethane coating. Corrosion Science, 178:109014. https://doi.org/10.1016/j.corsci.2020.109014

Chang XT, Chen XQ, Zhang QY, et al., 2021. Alumina nanoparticles-reinforced graphene-containing waterborne polyurethane coating for enhancing corrosion and wear resistance. Corrosion Communications, 4:1–11. https://doi.org/10.1016/j.corcom.2021.11.004

Cui ZL, Drioli E, Lee YM, 2014. Recent progress in fluoropolymers for membranes. Progress in Polymer Science, 39(1): 164–198. https://doi.org/10.1016/j.progpolymsci.2013.07.008

Douche D, Elmsellem H, Anouar EH, et al., 2020. Anti-corrosion performance of 8-hydroxyquinoline derivatives for mild steel in acidic medium: gravimetric, electrochemical, DFT and molecular dynamics simulation investigations. Journal of Molecular Liquids, 308:113042. https://doi.org/10.1016/j.molliq.2020.113042

Ghanbari A, Bordbar-Khiabani A, Warchomicka F, et al., 2023. PEO/polymer hybrid coatings on magnesium alloy to improve biodegradation and biocompatibility properties. Surfaces and Interfaces, 36:102495. https://doi.org/10.1016/j.surfin.2022.102495

Giannetti E, 2005. Thermal stability and bond dissociation energy of fluorinated polymers: a critical evaluation. Journal of Fluorine Chemistry, 126(4):623–630. https://doi.org/10.1016/j.jfluchem.2005.01.008

Haeri Z, Ramezanzadeh B, Ramezanzadeh M, 2022. Recent progress on the metal-organic frameworks decorated graphene oxide (MOFs-GO) nano-building application for epoxy coating mechanical-thermal/flame-retardant and anticorrosion features improvement. Progress in Organic Coatings, 163:106645. https://doi.org/10.1016/j.porgcoat.2021.106645

Hsissou R, Benzidia B, Hajjaji N, et al., 2018. Elaboration and electrochemical studies of the coating behavior of a new nanofunctional epoxy polymer on E24 steel in 3.5% NaCl. Portugaliae Electrochimica Acta, 36(4):259–270. https://doi.org/10.4152/pea.201804259

Hsissou R, Benhiba F, Echihi S, et al., 2021. Performance of curing epoxy resin as potential anticorrosive coating for carbon steel in 3.5% NaCl medium: combining experimental and computational approaches. Chemical Physics Letters, 783:139081. https://doi.org/10.1016/j.cplett.2021.139081

Hsissou R, Azogagh M, Benhiba F, et al., 2022a. Insight of development of two cured epoxy polymer composite coatings as highly protective efficiency for carbon steel in sodium chloride solution: DFT, RDF, FFV and MD approaches. Journal of Molecular Liquids, 360:119406. https://doi.org/10.1016/j.molliq.2022.119406

Hsissou R, Benhiba F, El Aboubi M, et al., 2022b. Synthesis and performance of two ecofriendly epoxy resins as a highly efficient corrosion inhibition for carbon steel in 1 M HCl solution: DFT, RDF, FFV and MD approaches. Chemical Physics Letters, 806:139995. https://doi.org/10.1016/j.cplett.2022.139995

Huttunen-Saarivirta E, Yudin VE, Myagkova LA, et al., 2011. Corrosion protection of galvanized steel by polyimide coatings: EIS and SEM investigations. Progress in Organic Coatings, 72(3):269–278. https://doi.org/10.1016/j.porgcoat.2011.04.015

Kajánek D, Hadzima B, Buhagiar J, et al., 2019. Corrosion degradation of AZ31 magnesium alloy coated by plasma electrolytic oxidation. Transportation Research Procedia, 40:51–58. https://doi.org/10.1016/j.trpro.2019.07.010

Lei HB, He DL, Guo YN, et al., 2018. Synthesis and characterization of UV-absorbing fluorine-silicone acrylic resin polymer. Applied Surface Science, 442:71–77. https://doi.org/10.1016/j.apsusc.2018.02.134

Liu CB, Qian B, Hou PM, et al., 2021. Stimulus responsive zeolitic imidazolate framework to achieve corrosion sensing and active protecting in polymeric coatings. ACS Applied Materials & Interfaces, 13(3):4429–4441. https://doi.org/10.1021/acsami.0c22642

Liu G, Pan J, Xu XL, et al., 2020. Preparation of ECTFE porous membrane with a green diluent TOTM and performance in VMD process. Journal of Membrane Science, 612:118375. https://doi.org/10.1016/j.memsci.2020.118375

M<UP>OHURD</UP> (Ministry of Housing and Urban-Rural Development of the People’s Republic of China), 2009. Corrosion of Metals and Alloys-Electrochemical Test Methods–Guidelines for Conducting Potentiostatic and Potentiodynamic Polarization Measurements, GB/T 24196–2009. National Standards of the People’s Republic of China (in Chinese).

M<UP>OHURD</UP> (Ministry of Housing and Urban-Rural Development of the People’s Republic of China), 2021. Paints and Varnishes-Cross-Cut Test, GB/T 9286–2021. National Standards of the People’s Republic of China (in Chinese).

Molhi A, Hsissou R, Damej M, et al., 2021. Contribution to the corrosion inhibition of C38 steel in 1 M hydrochloric acid medium by a new epoxy resin PGEPPP. International Journal of Corrosion and Scale Inhibition, 10(1):399–418. https://doi.org/10.17675/2305-6894-2021-10-1-23

Pan J, Ma WY, Huang LL, et al., 2021. Fabrication and characterization of ECTFE hollow fiber membranes via low-temperature thermally induced phase separation (L-TIPS). Journal of Membrane Science, 634:119429. https://doi.org/10.1016/j.memsci.2021.119429

Rudnev VS, Vaganov-Vil’kins AA, Yarovaya TP, et al., 2016. Polytetrafluoroethylene-oxide coatings on aluminum alloys. Surface and Coatings Technology, 307:1249–1254. https://doi.org/10.1016/j.surfcoat.2016.07.035

Sengupta S, Murmu M, Mandal S, et al., 2021. Competitive corrosion inhibition performance of alkyl/acyl substituted 2-(2-hydroxybenzylideneamino) phenol protecting mild steel used in adverse acidic medium: a dual approach analysis using FMOs/molecular dynamics simulation corroborated experimental findings. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 617:126314. https://doi.org/10.1016/j.colsurfa.2021.126314

Shen GZ, Zhang LY, Wu W, et al., 2022. Design and fabrication of enhanced corrosion-resistant LDH-Zn-G/Ni duallayer structural coatings on magnesium alloys. Journal of Alloys and Compounds, 917:165475. https://doi.org/10.1016/j.jallcom.2022.165475

Simone S, Figoli A, Santoro S, et al., 2012. Preparation and characterization of ECTFE solvent resistant membranes and their application in pervaporation of toluene/water mixtures. Separation and Purification Technology, 90:147–161. https://doi.org/10.1016/j.seppur.2012.02.022

Singh L, Devgan K, Samra KS, 2012. Effect of swift heavy ion irradiation on ethylene-chlorotrifluoroethylene copolymer. Radiation Physics and Chemistry, 81(11): 1741–1746. https://doi.org/10.1016/j.radphyschem.2012.06.006

Steffi AP, Balaji R, Chen SM, et al., 2021. Rational construction of SiO2/MoS2/TiO2 composite nanostructures for antibiofouling and anti-corrosion applications. ChemistrySelect, 6(5):917–927. https://doi.org/10.1002/slct.202004263

Steffi AP, Balaji R, Chandrasekar N, et al., 2022a. Highperformance anti-corrosive coatings based on rGO-SiO2-TiO2 ternary heterojunction nanocomposites for superior protection for mild steel specimens. Diamond and Related Materials, 125:108968. https://doi.org/10.1016/j.diamond.2022.108968

Steffi AP, Balaji R, Prakash N, et al., 2022b. Incorporation of SiO2 functionalized gC3N4 sheets with TiO2 nanoparticles to enhance the anticorrosion performance of metal specimens in aggressive Cl− environment. Chemosphere, 290:133332. https://doi.org/10.1016/j.chemosphere.2021.133332

Wan S, Chen HK, Ma XZ, et al., 2021. Anticorrosive reinforcement of waterborne epoxy coating on Q235 steel using NZ/BNNS nanocomposites. Progress in Organic Coatings, 159:106410. https://doi.org/10.1016/j.porgcoat.2021.106410

Wang H, Xu JH, Du XS, et al., 2021. A self-healing polyurethane-based composite coating with high strength and anticorrosion properties for metal protection. Composites Part B: Engineering, 225:109273. https://doi.org/10.1016/j.compositesb.2021.109273

Wang HH, Duan YH, Ma XT, et al., 2021. Polyisocyanate bridged environmental graphene/epoxy nanocomposite coatings with excellent anticorrosion performance. Progress in Organic Coatings, 153:106167. https://doi.org/10.1016/j.porgcoat.2021.106167

Wang KL, Hong S, Wei Z, et al., 2021. Long-term corrosion behavior of HVOF sprayed Cr3C2-NiCr coatings in sulfide-containing 3.5 wt.% NaCl solution. Journal of Materials Research and Technology, 15:3122–3132. https://doi.org/10.1016/j.jmrt.202L09.131

Xiang YX, He Y, Tang WW, et al., 2021. Fabrication of robust Ni-based TiO2 composite@TTOS superhydrophobic coating for wear resistance and anti-corrosion. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 629:127394. https://doi.org/10.1016/j.colsurfa.2021.127394

Xu LY, Fu XJ, Su HJ, et al., 2022. Corrosion and tribocorrosion protection of AZ31B Mg alloy by a hydrothermally treated PEO/chitosan composite coating. Progress in Organic Coatings, 170:107002. https://doi.org/10.1016/j.porgcoat.2022.107002

Yan ST, Tang P, Ling ZW, et al., 2022. An analytical investigation of the collapse of asymmetrically corroded pipes under external pressure. Journal of Zhejiang University-SCIENCE A (Applied Physics & Engineering), 23(5):358–374. https://doi.org/10.1631/jzus.A2100487

Yang SH, Fang H, Li H, et al., 2022. Synthesis of tung oil-based vinyl ester resin and its application for anti-corrosion coatings. Progress in Organic Coatings, 170:106967. https://doi.org/10.1016/j.porgcoat.2022.106967

Yao N, Chau J, Elele E, et al., 2017. Characterization of microporous ECTFE membrane after exposure to different liquid media and radiation. Journal of Membrane Science, 532: 89–104. https://doi.org/10.1016/j.memsci.2017.03.007

Zavareh MA, Sarhan AADM, Zavareh PA, et al., 2016. Electrochemical corrosion behavior of carbon steel pipes coated with a protective ceramic layer using plasma and HVOF thermal spray techniques for oil and gas. Ceramics International, 42(2):3397–3406. https://doi.org/10.1016/j.ceramint.2015.10.134

Zhang WY, Zhang T, Zhu ZX, et al., 2022. Corrosion electrochemistry properties of thermally sprayed Zn-Cu-Ti coating in simulated ocean atmosphere. Journal of Materials Research and Technology, 21:3235–3247. https://doi.org/10.1016/j.jmrt2022.10.108

Zhang ZQ, Li YL, Zhu XY, et al., 2021. Meso-scale corrosion expansion cracking of ribbed reinforced concrete based on a 3D random aggregate model. Journal of Zhejiang University-SCIENCE A (Applied Physics & Engineering), 22(11):924–940. https://doi.org/10.1631/jzus.A2100304

Zhao HR, Ding JH, Liu PL, et al., 2021. Boron nitride-epoxy inverse “nacre-like” nanocomposite coatings with superior anticorrosion performance. Corrosion Science, 183:109333. https://doi.org/10.1016/j.corsci.2021.109333

Acknowledgments

This work is supported by the Zhejiang Postdoctoral Merit-Based Funding (No. ZJ2020030), the China Postdoctoral Science Foundation (No. 2020M681920), and the Zhejiang Sci-Tech University Youth Innovation Program (No. 2021Q038), China.

Author information

Authors and Affiliations

Contributions

Minjia WANG designed the research. Peihu SHEN and Jun WEN finished the experiments. Minjia WANG and Peihu SHEN processed the corresponding data. Peihu SHEN wrote the first draft of the manuscript. Biqin DONG and Hedong LI helped to organize the manuscript and revised the first draft. Peihu SHEN and Minjia WANG revised further and edited the final version.

Corresponding author

Ethics declarations

Peihu SHEN, Jun WEN, Biqin DONG, Hedong LI, and Minjia WANG declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Shen, P., Wen, J., Dong, B. et al. Corrosion behavior and protection mechanism of carbon steel coated with ethylene chlorotrifluoroethylene (ECTFE). J. Zhejiang Univ. Sci. A (2024). https://doi.org/10.1631/jzus.A2300157

Received:

Accepted:

Published:

DOI: https://doi.org/10.1631/jzus.A2300157