Abstract

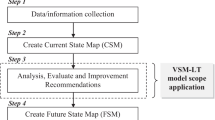

For efficient use of value stream mapping (VSM) for multi-varieties and small batch production in a data-rich environment enabled by Industry 4.0 technologies, a systematic framework of VSM to rejuvenate traditional lean tools is proposed. It addresses the issue that traditional VSM requires intensive on-site investigation and replies on experience, which hinders decisionmaking efficiency in dynamic and complex environments. The proposed framework follows the data-information-knowledge hierarchy model, and demonstrates how data can be collected in a production workshop, processed into information, and then interpreted into knowledge. In this paper, the necessity and limitations of VSM in automated root cause analysis are first discussed, with a literature review on lean production tools, especially VSM and VSM-based decision making in Industry 4.0. An implementation case of a furniture manufacturer in China is presented, where decision tree algorithm was used for automated root cause analysis. The results indicate that automated VSM can make good use of production data to cater for multi-varieties and small batch production with timely on-site waste identification and analysis. The proposed framework is also suggested as a guideline to renew other lean tools for reliable and efficient decision-making.

概要

目的

在工业4.0技术支持的数据丰富的环境下, 有效地利用价值流图(VSM)实现多品种、小批量生产.

创新点

1. 提出了一个利用VSM来激发传统精益工具活力的系统框架. 它解决了传统VSM在动态复杂环境下需要持续的现场调查和基于经验的响应, 从而影响决策效率的问题. 2. 提出了一个随着零部件加工逐步生成的能够反映动态生产现场的VSM. 3. 使用决策树算法来进行根本原因的自动化分析, 提高了生产现场的决策效率.

方法

1. 讨论VSM在自动化根本原因分析中的必要性和局限性, 并对精益生产工具进行文献综述, 特别是在工业4.0中基于VSM和VSM的决策. 2. 提出系统性框架(该框架遵循数据-信息-知识层次模型), 演示如何在生产车间中收集数据, 并将其处理为信息, 然后解释为知识. 3. 以中国某家具制造企业为例, 介绍框架的执行过程并采用决策树算法对根本原因进行自动分析.

结论

1. 自动化VSM可以很好地利用生产数据, 满足多品种、 小批量生产的要求, 并能及时识别和分析现场的浪费. 2. 框架可以作为一个指导方针, 激发其他精益工具在工业4.0环境下的活力, 以便进行可靠和有效的决策.

Similar content being viewed by others

References

Badia A, 2014. Data, information, knowledge: an information science analysis. Journal of the Association for Information Science and Technology, 65(6):1279–1287. https://doi.org/10.1002/asi.23043

Balaji V, Venkumar P, Sabitha MS, et al., 2020. DVSMS: dynamic value stream mapping solution by applying IIoT. Sādhanā, 45(1):38. https://doi.org/10.1007/s12046-019-1251-5

Buer SV, Strandhagen JO, Chan FTS, 2018. The link between Industry 4.0 and lean manufacturing: mapping current research and establishing a research agenda. International Journal of Production Research, 56(8):2924–2940. https://doi.org/10.1080/00207543.2018.1442945

Chen JC, Chen KM, 2014. Application of ORFPM system for lean implementation: an industrial case study. The International Journal of Advanced Manufacturing Technology, 72(5–8):839–852. https://doi.org/10.1007/s00170-014-5710-1

Deuse J, Weisner K, Hengstebeck A, et al., 2015. Gestaltung von produktionssystemen im kontext von industrie 4.0. In: Botthof A, Hartmann EA (Eds.), Zukunft der Arbeit in Industrie 4.0. Springer Vieweg, Berlin, Germany, p.99–109 (in German). https://doi.org/10.1007/978-3-662-45915-7_11

Dombrowski U, Richter T, Krenkel P, 2017. Interdependencies of industrie 4.0 & lean production systems: a use cases analysis. Procedia Manufacturing, 11:1061–1068. https://doi.org/10.1016/j.promfg.2017.07.217

Dotoli M, Fanti MP, Rotunno G, et al., 2011. A lean manufacturing procedure using value stream mapping and the analytic hierarchy process. Proceedings of IEEE International Conference on Systems, Man, and Cybernetics, p.1193–1198. https://doi.org/10.1109/icsmc.2011.6083860

Drath R, Horch A, 2014. Industrie 4.0: hit or hype? [industry forum]. IEEE Industrial Electronics Magazine, 8(2):56–58. https://doi.org/10.1109/mie.2014.2312079

Fonseca LM, 2018. Industry 4.0 and the digital society: concepts, dimensions and envisioned benefits. Proceedings of the International Conference on Business Excellence, 12(1):386–397. https://doi.org/10.2478/picbe-2018-0034

Gao Q, Shi RB, Wang G, 2016. Construction of intelligent manufacturing workshop based on lean management. Procedia CIRP, 56:599–603. https://doi.org/10.1016/j.procir.2016.10.118

Hartmann L, Meudt T, Seifermann S, et al., 2018. Value stream method 4.0: holistic method to analyse and design value streams in the digital age. Procedia CIRP, 78:249–254. https://doi.org/10.1016/j.procir.2018.08.309

Huang ZY, Kim J, Sadri A, et al., 2019. Industry 4.0: development of a multi-agent system for dynamic value stream mapping in SMEs. Journal of Manufacturing Systems, 52:1–12.

Kagermann H, Wahlster W, Helbig J, 2013. Securing the Future of German Manufacturing Industry: Recommendations for Implementing the Strategic Initiative Industrie 4.0. Final Report of the Industrie 4.0 Working Group.

Khanchanapong T, Prajogo D, Sohal AS, et al., 2014. The unique and complementary effects of manufacturing technologies and lean practices on manufacturing operational performance. International Journal of Production Economics, 153:191–203. https://doi.org/10.1016/j.ijpe.2014.02.021

Kolberg D, Knobloch J, Zühlke D, 2017. Towards a lean automation interface for workstations. International Journal of Production Research, 55(10):2845–2856. https://doi.org/10.1080/00207543.2016.1223384

Ku CC, Chien CF, Ma KT, 2020. Digital transformation to empower smart production for industry 3.5 and an empirical study for textile dyeing. Computers & Industrial Engineering, 142:106297. https://doi.org/10.1016/j.cie.2020.106297

Lian YH, van Landeghem H, 2007. Analysing the effects of lean manufacturing using a value stream mapping-based simulation generator. International Journal of Production Research, 45(13):3037–3058. https://doi.org/10.1080/00207540600791590

Lins T, Oliveira RAR, 2020. Cyber-physical production systems retrofitting in context of industry 4.0. Computers & Industrial Engineering, 139:106193. https://doi.org/10.1016/j.cie.2019.106193

Longo F, Nicoletti L, Padovano A, 2017. Smart operators in industry 4.0: a human-centered approach to enhance operators’ capabilities and competencies within the new smart factory context. Computers & Industrial Engineering, 113:144–159. https://doi.org/10.1016/j.cie.2017.09.016

Ma J, Wang Q, Zhao ZB, 2017. SLAE-CPS: smart lean automation engine enabled by cyber-physical systems technologies. Sensors, 17(7):1500. https://doi.org/10.3390/s17071500

Mayr A, Weigelt M, Kühl A, et al., 2018. Lean 4.0-a conceptual conjunction of lean management and industry 4.0. Procedia CIRP, 72:622–628. https://doi.org/10.1016/j.procir.2018.03.292

Meudt T, Metternich J, Abele E, 2017. Value stream mapping 4.0: holistic examination of value stream and information logistics in production. CIRP Annals, 66(1):413–416. https://doi.org/10.1016/j.cirp.2017.04.005

Moeuf A, Pellerin R, Lamouri S, et al., 2018. The industrial management of SMEs in the era of industry 4.0. International Journal of Production Research, 56(3):1118–1136. https://doi.org/10.1080/00207543.2017.1372647

Papacharalampopoulos A, Giannoulis C, Stavropoulos P, et al., 2020. A digital twin for automated root-cause search of production alarms based on KPIs aggregated from IoT. Applied Sciences, 10(7):2377. https://doi.org/10.3390/app10072377

Peruzzini M, Gregori F, Luzi A, et al., 2017. A social life cycle assessment methodology for smart manufacturing: the case of study of a kitchen sink. Journal of Industrial Information Integration, 7:24–32. https://doi.org/10.1016/j.jii.2017.04.001

Prinz C, Kreggenfeld N, Kuhlenkotter B, 2018. Lean meets industrie 4.0-a practical approach to interlink the method world and cyber-physical world. Procedia Manufacturing, 23:21–26. https://doi.org/10.1016/j.promfg.2018.03.155

Rahani AR, Al-Ashraf M, 2012. Production flow analysis through value stream mapping: a lean manufacturing process case study. Procedia Engineering, 41:1727–1734. https://doi.org/10.1016/j.proeng.2012.07.375

Ramadan M, 2016. RFID-enabled Dynamic Value Stream Mapping for Smart Real-time Lean-based Manufacturing System. PhD Thesis, University of Duisburg-Essen, Duisburg, Germany.

Ramadan M, Al-Maimani H, Noche B, 2017. RFID-enabled smart real-time manufacturing cost tracking system. The International Journal of Advanced Manufacturing Technology, 89(1–4):969–985. https://doi.org/10.1007/s00170-016-9131-1

Ramadan M, Salah B, Othman M, et al., 2020. Industry 4.0-based real-time scheduling and dispatching in lean manufacturing systems. Sustainability, 12(6):2272. https://doi.org/10.3390/su12062272

Rohani JM, Zahraee SM, 2015. Production line analysis via value stream mapping: a lean manufacturing process of color industry. Procedia Manufacturing, 2:6–10. https://doi.org/10.1016/j.promfg.2015.07.002

Rossini M, Costa F, Staudacher AP, et al., 2019. Industry 4.0 and lean production: an empirical study. IFAC-PapersOnLine, 52(13):42–47. https://doi.org/10.1016/j.ifacol.2019.11.122

Sanders A, Elangeswaran C, Wulfsberg J, 2016. Industry 4.0 implies lean manufacturing: research activities in industry 4.0 function as enablers for lean manufacturing. Journal of Industrial Engineering and Management, 9(3):811–833. https://doi.org/10.3926/jiem.1940

Schönemann M, Kurle D, Herrmann C, et al., 2016. Multi-product EVSM simulation. Procedia CIRP, 41:334–339. https://doi.org/10.1016/j.procir.2015.10.012

Shahin M, Chen FF, Bouzary H, et al., 2020. Integration of lean practices and industry 4.0 technologies: smart manufacturing for next-generation enterprises. The International Journal of Advanced Manufacturing Technology, 107(5–6):2927–2936. https://doi.org/10.1007/s00170-020-05124-0

Solding P, Gullander P, 2009. Concepts for simulation based value stream mapping. Proceedings of the Winter Simulation Conference, p.2231–2237. https://doi.org/10.1109/WSC.2009.5429185

Stadnicka D, Litwin P, 2019. Value stream mapping and system dynamics integration for manufacturing line modelling and analysis. International Journal of Production Economics, 208:400–411. https://doi.org/10.1016/j.ijpe.2018.12.011

Tamás P, 2016. Application of value stream mapping at flexible manufacturing systems. Key Engineering Materials, 686:168–173. https://doi.org/10.4028/www.scientific.net/KEM.686.168

Uriarte AG, Ng AHC, Moris MU, 2018. Supporting the lean journey with simulation and optimization in the context of industry 4.0. Procedia Manufacturing, 25:586–593. https://doi.org/10.1016/j.promfg.2018.06.097

Wagner T, Herrmann C, Thiede S, 2017. Industry 4.0 impacts on lean production systems. Procedia CIRP, 63:125–131. https://doi.org/10.1016/j.procir.2017.02.041

Xu LD, Xu EL, Li L, 2018. Industry 4.0: state of the art and future trends. International Journal of Production Research, 56(8):2941–2962. https://doi.org/10.1080/00207543.2018.1444806

Author information

Authors and Affiliations

Corresponding author

Additional information

Project supported by the National Natural Science Foundation of China (Nos. 72071179 and 51805479), the Natural Science Foundation of Zhejiang Province (No. LY19E050019), and the Ministry of Industry and Information Technology of China (No. Z135060009002)

Contributors

Hao-nan WANG: investigation; formal analysis; methodology; writing-original draft; visualization; validation. Qi-qi HE: methodology; data curation; investigation; validation. Zheng ZHANG: methodology; resources; investigation. Tao PENG: conceptualization; writing-review and editing; supervision. Ren-zhong TANG: project administration; resources; funding acquisition; supervision.

Conflict of interest

Hao-nan WANG, Qi-qi HE, Zheng ZHANG, Tao PENG, and Ren-zhong TANG declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Wang, Hn., He, Qq., Zhang, Z. et al. Framework of automated value stream mapping for lean production under the Industry 4.0 paradigm. J. Zhejiang Univ. Sci. A 22, 382–395 (2021). https://doi.org/10.1631/jzus.A2000480

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1631/jzus.A2000480

Key words

- Value stream mapping (VSM)

- Root cause analysis

- Automated decision-making

- Lean production tools

- Industry 4.0