Abstract

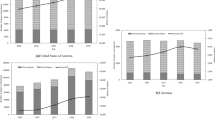

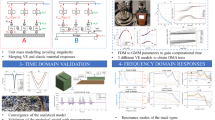

The dynamic model of a high-speed electric multiple unit (EMU) is established based on the theory of rigid-flexible coupling multi-body system dynamics. Depending on the actual operating conditions of the vehicle, there are a variety of conditions of car body load-time history. We assess ineffective amplitude omission, load spectrum extrapolation, and extreme determination through the car body load-time history, and then obtain the car body fatigue load block spectrum. Finally, we perform a fatigue strength test on the whole car body on a car body fatigue test bench. It is shown that the accelerations of the three directions of the vehicle car body increase with increasing speed. When the train passes a curve, the lateral acceleration average becomes greater. There is also an increase in the car body accelerations in three directions when the train goes through a turnout or twisted line. Under the condition of a failed spring, the vertical acceleration of the car body is obviously increased. Anti-yaw damper failure will cause a significant increase in vehicle lateral acceleration. The failure of lateral and vertical dampers on the second suspension causes an insignificant acceleration increase in three directions. The car body acceleration increases the wear-type profile relative to the original profile in various working and speed level conditions a little. The influence on the damage of vehicle car body under various working conditions is predicted according to the obtained load spectrum.

概要

目的

基于动力学仿真载荷谱对动车组车体进行疲劳损 伤评估,并在试验台上进行验证。

创新点

1. 基于动力学仿真得到车体服役载荷谱;2. 通过 损伤评估得到车体在各种工况下的疲劳损伤,并 在试验台上将载荷谱应用于整车车体。

方法

1. 通过动力学仿真,对同一工况不同速度等级、 不同线路条件、不同故障工况和不同踏面情况下 得到的载荷谱进行分析。2. 利用车体的加速度载 荷时间历程对其进行结构疲劳寿命预测分析,得 到各个工况下的损伤值。

结论

1. 随着速度的提高,车体三个方向的加速度越来 越大;列车通过曲线时,横向加速度均值偏大; 道岔通过和扭曲线路都会引起车体三个方向加 速度的增加;空簧失效条件下,车体垂向加速度 明显增大;抗蛇行减振器失效会引起车体横向加 速度的明显增加;二系横向和垂向减振器的失效 会引起三个方向的加速度增大,但是不明显;在 各个工况及速度级条件下,相对于原始踏面,车 体在磨耗型踏面的加速度更大。2. 对所得车体加 速度载荷时间历程进行功率谱密度函数分析发 现,各种条件下的车体振动能量主要集中在 20 Hz 以下。3. 随着速度的增加,车体损伤增加; 磨耗型踏面比非磨耗型踏面对车体损伤大;故障 工况下,当速度小于200 km/h 时,只有空簧失效 对车体损伤较大;当速度大于200 km/h 时,抗蛇 行减振器失效对车体产生的损伤最大;道岔和扭 曲线路会对车体产生一定的损伤,但影响不大; 当列车进行牵引制动时,随着速度的提高,损伤 也相应增加,并且当牵引速度大于300 km/h 时, 损伤会急剧增加。

Similar content being viewed by others

References

AAR (Association of American Railroad), 1999. Locomotive and Rolling Stock Standard Manual. AAR, Washington, USA.

BSI (British Standards Institution), 2014. Guide to Fatigue Design and Assessment of Steel Products, BS 7608:2014. BSI, London, UK.

Gongjiang MS, 2003. The strength of carbody for Shinkansen cars and safety evaluation. Foreign Rolling Stock, 40(6):12–16 (in Chinese). https://doi.org/10.3969/j.issn.1002-7610.2003.06.004

Gou G, Zhang M, Chen H, et al., 2015. Effect of humidity on porosity, microstructure, and fatigue strength of A7N01S-T5 aluminum alloy welded joints in high-speed trains. Materials & Design, 85:309–317. https://doi.org/10.1016/j.matdes.2015.06.177

Gutiérrez-Carvajal RE, Betancur GR, Barbosa J, et al., 2018. Full scale fatigue test performed to the bolster beam of a railway vehicle. International Journal on Interactive Design and Manufacturing (IJIDeM), 12(1):253–261. https://doi.org/10.1007/s12008-016-0361-0

Hou B, 2016. The Load Spectrum Study on High-speed EMU Body. MS Thesis, Southwest Jiaotong University, Chengdu, China (in Chinese).

IIW (International Institute of Welding), 2016. Recommendations for Fatigue Design of Welded Joints and Components, IIW-2259-15:2016. IIW, Wilhelmshaven, Germany.

Ju YZ, 2013. High-speed EMU Aluminum Alloy Weld Fatigue Life Prediction of Vehicle. MS Thesis, Dalian Jiaotong University, Dalian, China (in Chinese).

Jun HK, Jung HS, Lee DH, et al., 2010. Fatigue crack evaluation on the underframe of EMU carbody. Procedia Engineering, 2(1):893–900. https://doi.org/10.1016/j.proeng.2010.03.096

Li FS, 2018. Research on Vibration and Fatigue of Carbody for EMU under Service Environment. PhD Thesis, Southwest Jiaotong University, Chengdu, China (in Chinese).

Li XF, 2008. Predicting Fatigue Life of Rail Vehicle Welded Structure Based on Virtual Fatigue Test. PhD Thesis, Dalian Jiaotong University, Dalian, China (in Chinese).

Liu K, 2013. The Research of Ability of Anti-fatigue for Aluminum Alloy Car Body. MS Thesis, Dalian Jiaotong University, Dalian, China (in Chinese).

Liu YB, 2015. Analysis on Ground Effects of High-speed Trains and the Resultant Fatigue Damage to the Equipment Bay. PhD Thesis, Beijing Jiaotong University, Beijing, China (in Chinese).

Lu X, 2010. Vibration Fatigue Life Analysis on Rigid-flexible Coupling of CRH3 Car Body. MS Thesis, Dalian Jiaotong University, Dalian, China (in Chinese).

Lu YH, Dang LY, Zhang X, et al., 2018a. Analysis of the dynamic response and fatigue reliability of a full-scale carbody of a high-speed train. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 232(7):2006–2023. https://doi.org/10.1177/0954409718757295

Lu YH, Zheng HY, Lu C, et al., 2018b. Analysis methods of the dynamic structural stress in a full-scale welded car-body for high-speed trains. Advances in Mechanical Engineering, 10(10):1–16. https://doi.org/10.1177/1687814018805917

Miao BR, Zhang LM, Zhang WH, et al., 2010. High-speed train carbody structure fatigue simulation based on dynamic characteristics of the overall vehicle. Journal of the China Railway Society, 32(6):101–108 (in Chinese). https://doi.org/10.3969/j.issn.1001-8360.2010.06.017

Oomura K, Okuno S, Kawai S, et al., 1992. Fatigue test of an actual car body structure (1st report, the testing method and its accuracy). Transactions of the Japan Society of Mechanical Engineers Series A, 58(545):20–25 (in Japanese).

Qin HF, 2017. Study on the Load Spectrum of Chinese Standard EMUs. MS Thesis, Beijing Jiaotong University, Beijing, China (in Chinese).

Song Y, Wu PB, Jia L, 2016. Study of the fatigue testing of a car body underframe for a high-speed train. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 230(6):1614–1625. https://doi.org/10.1177/0954409715618425

Wang YW, 2015. The Corbel Fatigue Strength of CRH-2 EMU Based on the Measured Load. MS Thesis, Beijing Jiaotong University, Beijing, China (in Chinese).

Wang ZY, 2016. The Study on the Vibration Fatigue of Mono-car Body Made of Aluminum Alloy. MS Thesis, Southwest Jiaotong University, Chengdu, China (in Chinese).

Wei QS, 2018. Study on Fatigue Crack Propagation of the Al Alloy Crossbeam in High Speed EMU Car Body. MS Thesis, Beijing Jiaotong University, Beijing, China (in Chinese).

Xie JL, Zhang Y, Xie YY, 2010. Dynamic response and fatigue strength of depressed center flat frame. Journal of Mechanical Engineering, 46(16):16–22 (in Chinese). https://doi.org/10.3901/JME.2010.16.016

Xue GJ, 2013. Inference and Calibration of Rail Vehicles Load Spectrum Based on Mathematical Statistics Methods. MS Thesis, Beijing Jiaotong University, Beijing, China (in Chinese).

Yan X, 2009. The Compile of Longitudinal Load Spectrum for Da-Qin Line 20,000-ton Heavy-load Train. MS Thesis, Beijing Jiaotong University, Beijing, China (in Chinese).

Yan XD, 2014. Reliability Study of High Speed Train Equipment Bay Bottom Plates. MS Thesis, Beijing Jiaotong University, Beijing, China (in Chinese).

Yang GW, 2005. Simulation of Prediction of Fatigue Life for Component of Railway Vehicle. PhD Thesis, Southwest Jiaotong University, Chengdu, China (in Chinese).

Yang YB, Liang XJ, Hung HH, et al., 2017. Comparative study of 2D and 2.5D responses of long underground tunnels to moving train loads. Soil Dynamics and Earthquake Engineering, 97:86–100. https://doi.org/10.1016/j.soildyn.2017.02.005

Zhang SG, 2008. Study on testing and establishment method for the load spectrum of bogie frame for high-speed trains. Science in China Series E: Technological Sciences, 51(12):2142–2151. https://doi.org/10.1007/s11431-009-0025-4

Zhang SX, 2016. Load Spectrum Compiling and Life Prediction Simulation of High Speed Train Car Body Based on the Acceleration Life Test. MS Thesis, Southwest Jiaotong University, Chengdu, China (in Chinese).

Author information

Authors and Affiliations

Contributions

Huan-yun DAI designed the research. Lu JIA and Ye SONG processed the corresponding data. Lu JIA wrote the first draft of the manuscript. Huan-yun DAI and Ye SONG helped to organize the manuscript. Lu JIA and Ye SONG revised and edited the final version.

Corresponding author

Additional information

Conflict of interest

Lu JIA, Huan-yun DAI, and Ye SONG declare that they have no conflict of interest.

Project supported by the Science and Technology Innovation Program of Central Universities (No. 2682019CX45), China

Rights and permissions

About this article

Cite this article

Jia, L., Dai, Hy. & Song, Y. Test technology research and fatigue damage prediction of a car body based on dynamic simulation load spectrum. J. Zhejiang Univ. Sci. A 21, 923–937 (2020). https://doi.org/10.1631/jzus.A1900662

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1631/jzus.A1900662