Abstract

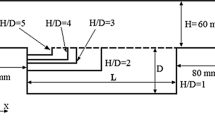

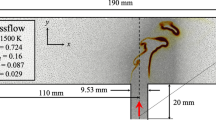

Large eddy simulations (LESs) of cavity ignition processes were performed in a 2D ethylene-fueled supersonic combustor with a single rear-wall-expansion cavity based on OpenFOAM. The ethylene combustion was modelled using a 35-step with 20-specie ethylene chemical mechanism, which had been validated by CHEMKIN calculations. The effect on the ignition process of different ignition sites inside the cavity was then studied. It was found that the rear region of the cavity floor is an optimized ignition site where successful ignitions will be achieved. According to different ignition behaviors, two flame extinguishing modes could be identified: blown-off extinguishing mode and flow dissipation extinguishing mode. Blown-off extinguishing mode mainly occurred after ignition near the cavity shear layer, in which the initial flame was blown off directly due to the high speed of the supersonic core flow. Flow dissipation extinguishing mode is likely to occur after ignition near the front and middle cavity floor as a result of severe turbulent dissipations and limited chemical reactions. The study indicates that the movement routine of the initial flame is important for the ignition process, including both moving towards a favorable flow field and forming a large heat release region along the movement.

目的

超燃冲压发动机的点火过程是超声速燃烧领域的 重要课题之一。目前, 针对超燃冲压发动机燃烧 室点火过程的研究以实验研究为主, 数值研究则 相对较少。本文旨在基于大涡模拟研究点火位置 对点火过程的影响, 并在此基础上分析导致点火 失败的原因。

创新点

1. 基于大涡模拟, 研究点火位置对点火过程建立 的影响; 2. 发现了流动耗散和直接吹熄两种熄火 模式。

方法

1. 基于CHEMKIN, 选择合适的化学反应机理; 2. 在简化化学反应机理的基础上, 利用大涡模拟 研究不同点火位置对点火过程的影响; 3. 分析数 值仿真数据, 寻找能成功实现点火的点火位置, 并探讨导致点火失败的因素。

结论

1. 在凹腔后缘处点火可以成功实现发动机点火; 2. 发现了两种点火失败的模式, 即流动耗散模式 和直接吹熄模式; 3. 流动耗散模式主要发生在凹 腔前缘和凹腔中部, 而直接吹熄模式主要发生在 剪切层中。

Similar content being viewed by others

References

Barnes FW, Segal C, 2015. Cavity-based flameholding for chemically-reacting supersonic flow. Progress in Aerospace Sciences, 76:24–41. https://doi.org/10.1016/j.paerosci.2015.04.002

Baurle RA, Mathur T, Gruber MR, et al., 1998. A numerical and experimental investigation of a scramjet combustor for hypersonic missile applications. Proceedings of the 34th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit. https://doi.org/10.2514/6.1998-3121

Ben-Yakar A, Hanson RK, 2001. Cavity flame-holders for ignition and flame stabilization in scramjets: an overview. Journal of Propulsion and Power, 17(4):869–877. https://doi.org/10.2514/2.5818

Beresh SJ, Wagner JL, Casper KM, 2016. Compressibility effects in the shear layer over a rectangular cavity. Journal of Fluid Mechanics, 808:116–152. https://doi.org/10.1017/jfm.2016.540

Cai Z, Liu X, Gong C, et al., 2016. Large eddy simulation of the fuel transport and mixing process in a scramjet combustor with rearwall-expansion cavity. Acta Astronautica, 126:375–381. https://doi.org/10.1016/j.actaastro.2016.05.010

Cai Z, Wang ZG, Sun MB, et al., 2017. Large eddy simulation of the flame propagation process in an ethylene fueled scramjet combustor in a supersonic flow. Proceedings of the 21st AIAA International Space Planes and Hypersonics Technologies Conference, p.2017–2148. https://doi.org/10.2514/6.2017-2148

Cai Z, Zhu JJ, Sun MB, et al., 2018a. Effect of cavity fueling schemes on the laser-induced plasma ignition process in a scramjet combustor. Aerospace Science and Technology, 78:197–204. https://doi.org/10.1016/j.ast.2018.04.016

Cai Z, Sun MB, Wang ZG, et al., 2018b. Effect of cavity geometry on fuel transport and mixing processes in a scramjet combustor. Aerospace Science and Technology, 80:309–314. https://doi.org/10.1016/j.ast.2018.07.028

Cai Z, Zhu JJ, Sun MB, et al., 2018c. Ignition processes and modes excited by laser-induced plasma in a cavity-based supersonic combustor. Applied Energy, 228:1777–1782. https://doi.org/10.1016/j.apenergy.2018.07.079

Cai Z, Sun M, Wang Z, 2018d. Large eddy simulation of the flow structures and mixing fields in a rear-wall-expansion cavity. Proceedings of the 9th Asian Joint Conference on Propulsion and Power, AJCPP2018-091.

Cai Z, Zhu JJ, Sun MB, et al., 2018e. Spark-enhanced ignition and flame stabilization in an ethylene-fueled scramjet combustor with a rear-wall-expansion geometry. Experimental Thermal and Fluid Science, 92:306–313. https://doi.org/10.1016/)j.expthermflusci.2017.12.007

Chang JT, Zhang JL, Bao W, et al., 2018. Research progress on strut-equipped supersonic combustors for scramjet application. Progress in Aerospace Sciences, 103:1–30. https://doi.org/10.1016/j.paerosci.2018.10.002

Curran ET, 2001. Scramjet engines: the first forty years. Journal of Propulsion and Power, 17(6):1138–1148. https://doi.org/10.2514/2.5875

Dong G, Fan BC, Ye JF, 2008. Numerical investigation of ethylene flame bubble instability induced by shock waves. Shock Waves, 17(6):409–419. https://doi.org/10.1007/s00193-008-0124-3

Egolfopoulos FN, Law CK, 1991. An experimental and computational study of the burning rates of ultra-lean to moderately-rich H2/O2/N2 laminar flames with pressure variations. Symposium (International) on Combustion, 23(1):333–340. https://doi.org/10.1016/S0082-0784(06)80276-6

Hassan MI, Aung KT, Kwon OC, et al., 1998. Properties of laminar premixed hydrocarbon/air flames at various pressures. Journal of Propulsion and Power, 14(4):479–488. https://doi.org/10.2514/2.5304

Huang W, Yan L, 2013. Progress in research on mixing techniques for transverse injection flow fields in supersonic crossflows. Journal of Zhejiang University-SCIENCE A (AppliedPhysics & Engineering), 14(8):554–564. https://doi.org/10.1631/jzus.A1300096

Huang W, Liu J, Yan L, et al., 2013. Multiobjective design optimization of the performance for the cavity flameholder in supersonic flows. Aerospace Science and Technology, 30(1):246–254. https://doi.org/10.1016/j.ast.2013.08.009

Huang W, Li MH, Ding F, et al., 2016. Supersonic mixing augmentation mechanism induced by a wall-mounted cavity configuration. Journal of Zhejiang University-SCIENCE A (Applied Physics & Engineering), 17(1):45–53. https://doi.org/10.1631/jzus.A1500244

Jomaas G, Zheng XL, Zhu DL, et al., 2005. Experimental determination of counterflow ignition temperatures and laminar flame speeds of C2-C3 hydrocarbons at atmospheric and elevated pressures. Proceedings of the Combustion Institute, 30(1):193–200. https://doi.org/10.1016/j.proci.2004.08.228

Kirik JW, Goyne CP, Peltier SJ, et al., 2014. Velocimetry measurements of a scramjet cavity flameholder with inlet distortion. Journal of Propulsion and Power, 30(6):1568–1576. https://doi.org/10.2514/LB35195

Kumar K, Mittal G, Sung CJ, et al., 2008. An experimental investigation of ethylene/O2/diluent mixtures: laminar flame speeds with preheat and ignition delays at high pressures. Combustion and Flame, 153(3):343–354. https://doi.org/10.1016/j.combustflame.2007.11.012

Li J, Ma FH, Yang V, et al., 2007. A comprehensive study of ignition transient in an ethylene-fueled scramjet combustor. Proceedings of the 43rd AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit. https://doi.org/10.2514/6.2007-5025

Li J, Zhang LW, Choi JY, et al., 2015. Ignition transients in a scramjet engine with air throttling part II: reacting flow. Journal of Propulsion and Power, 31(1):79–88. https://doi.org/10.2514/1.B35269

Liu X, Cai Z, Tong YH, et al., 2017. Investigation of transient ignition process in a cavity based scramjet combustor using combined ethylene injectors. Acta Astronautica, 137:1–7. https://doi.org/10.1016/j.actaastro.2017.04.007

Lv Z, Xia ZX, Liu B, et al., 2017. Preliminary experimental study on solid-fuel rocket scramjet combustor. Journal of Zhejiang University-SCIENCE A (Applied Physics & Engineering), 18(2):106–112. https://doi.org/10.1631/jzus.A1600489

Mathur T, Gruber M, Jackson K, et al., 2001. Supersonic combustion experiments with a cavity-based fuel injector. Journal of Propulsion and Power, 17(6):1305–1312. https://doi.org/10.2514/2.5879

Potturi AS, Edwards JR, 2015. Large-eddy/Reynolds-averaged Navier-Stokes simulation of cavity-stabilized ethylene combustion. Combustion and Flame, 162(4):1176–1192. https://doi.org/10.1016/j.combustflame.2014.10.011

Sun MB, Gong C, Zhang SP, et al., 2012. Spark ignition process in a scramjet combustor fueled by hydrogen and equipped with multi-cavities at Mach 4 flight condition. Experimental Thermal and Fluid Science, 43:90–96. https://doi.org/10.1016/j.expthermflusci.2012.03.028

Wang H, You XQ, Joshi AV, et al., 2007. USC Mech Version II. High-temperature Combustion Reaction Model of H2/CO/C1-C4 Compounds. University of Southern California, USA. http://ignis.usc.edu/USC_Mech_II.htm

Wang X, Zhong FQ, Gu HB, et al., 2015. Numerical study of combustion and convective heat transfer of a Mach 2.5 supersonic combustor. Applied Thermal Engineering, 89: 883–896. https://doi.org/10.1016/j.applthermaleng.2015.06.071

Wang ZG, Wang HB, Sun MB, 2014. Review of cavity-stabilized combustion for scramjet applications. Proceedings of the Institution of Mechanical Engineers, Part G: Journal of Aerospace Engineering, 228(14):2718–2735. https://doi.org/10.1177/0954410014521172

Wang ZG, Cai Z, Sun MB, et al., 2016. Large eddy simulation of the flame stabilization process in a scramjet combustor with rearwall-expansion cavity. International Journal of Hydrogen Energy, 41(42):19278–19288. https://doi.org/10.1016/j.ijhydene.2016.09.012

Yang V, Li J, Choi JY, et al., 2010. Ignition transient in an ethylene fueled scramjet engine with air throttling part II: ignition and flame development. Proceedings of the 48th AIAA Aerospace Sciences Meeting Including the New Horizons Forum and Aerospace Exposition. https://doi.org/10.2514/6.2010-410

Zhao Y, Liang J, Zhao Y, 2016. Non-reacting flow visualization of supersonic combustor based on cavity and cavity-strut flameholder. Acta Astronautica, 121:282–291. https://doi.org/10.1016/actaastro.2015.12.040).

Author information

Authors and Affiliations

Contributions

Zun CAI and Yong-chao SUN designed the research. Yong-chao SUN and Zun CAI processed the corresponding data and wrote the first draft of the manuscript. Tai-yu WANG and Ming-bo SUN helped to organize the manuscript. Cheng GONG and Yu-hui HUANG revised and edited the final version.

Corresponding author

Additional information

Conflict of interest

Yong-chao SUN, Zun CAI, Tai-yu WANG, Ming-bo SUN, Cheng GONG, and Yu-hui HUANG declare that they have no conflict of interest.

Project supported by the National Natural Science Foundation of China (Nos. 11902353 and 51706238) and the Postdoctoral Innovation Talent Support Program of China (No. BX20190091)

Rights and permissions

About this article

Cite this article

Sun, Yc., Cai, Z., Wang, Ty. et al. Numerical study on cavity ignition process in a supersonic combustor. J. Zhejiang Univ. Sci. A 21, 848–858 (2020). https://doi.org/10.1631/jzus.A1900419

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1631/jzus.A1900419