Abstract

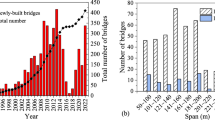

This paper aims to address the problem of geometric state control of large-segment steel box girders in offshore hoisting during the construction of large-span bridges. First, the geometric state control indexes of a large-segment steel box girder are determined, such as the manufacturing parameters of the top and bottom slabs, the width of the annular joint, and the support position. Second, the geometric state equations and state transfer matrixes of large-segment steel box girders under different conditions are deduced by taking the mileage and elevation of control points as basic state variables. In application of the geometric state transfer method in the construction control of the Hong Kong-Zhuhai-Macao Bridge, the width of the annular joint and the position parameters for the support of the large-segment steel box girder are predicted precisely. Moreover, the manufacturing parameters of the top and bottom slabs of the steel box girders are calculated reliably. The measured values show that the width of the annular joint is basically the same with the difference of less than 2 mm, the eccentricity of bridge support is less than 20 mm, and the elevation error of the bridge deck is within −10 mm to +15 mm, which meets the construction accuracy. Using the geometric state transfer method, the rapid and accurate installation of the Hong Kong-Zhuhai-Macao Bridge has been realized, demonstrating that the precise control of the geometric state of a steel box girder with ectopic installation and multi-state transition can be realized by using the geometric state transfer method.

目的

采用吊装施工的大节段钢箱梁属于整孔异位安 装,其几何状态从工厂到桥址不断转换、几何关 系复杂,且对成桥梁面标高、海上大节段环缝对 接以及桥梁支座定位均有非常高的精度要求。本 文研究基于几何状态传递的大节段钢箱梁吊装 施工控制方法,以解决分阶段施工桥梁在施工过 程中的几何状态控制难题。

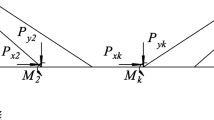

创新点:1. 确定大节段钢箱梁几何状态控制指标,即顶底 板下料参数、大节段环缝宽度和支座定位; 2. 提 出以钢箱梁控制点的里程和高程作为基本状态 变量,推导大节段钢箱梁各状态下的几何状态方 程和状态传递矩阵。

方法:1. 针对大节段钢箱梁吊装施工特点,进行状态分 析,提出其施工过程的典型几何状态,即设计成 桥状态、无应力状态、工厂组拼状态和安装状态; 2. 通过理论推导,构建各几何状态间的状态传递 方程,得出大节段钢箱梁吊装施工时结构的几何 状态变化关系;3. 基于上述推导的方程,计算大 节段钢箱梁下料参数、大节段钢箱梁环缝宽度和 支座定位参数,以指导施工;4. 在施工过程中对 桥梁结构实际响应数据进行测试,并将实测值与 理论值进行分析对比,以验证本文方法的可行性 和有效性。

结论:1. 采用本文方法实现了港珠澳大桥大节段钢箱梁 有应力状态下顶底板环缝宽度差值在2 mm 以 内、桥梁支座就位后的偏心距在20 mm 以内以及 成桥梁面高程误差范围为−10 mm~+15 mm,满足 控制精度要求。2. 以桥梁结构控制点的里程和高 程作为基本状态变量的几何状态控制方法可实 现桥梁施工过程中复杂几何关系传递的控制。 3. 本文方法具有通用性,可进一步推广应用于逐 孔顶推、节段拼装等异位安装以及多状态转换的 桥梁施工过程的几何状态控制。

Similar content being viewed by others

References

Arici M, Granata MF, 2007. Analysis of curved incrementally launched box concrete bridges using the Transfer Matrix Method. Bridge Structures, 3(3-4):165–181. https://doi.org/10.1080/15732480701510445

Breen JE, 1985. Controlling twist in precast segmental concrete bridges. PCI Journal, 30(4):86–111. https://doi.org/10.15554/pcij.07011985.86.111

Chen DW, Zheng XG, Xiang HF, 1993. A construction control system for P.C. cable-stayed bridges. China Civil Engineering Journal, 26(1):1–11 (in Chinese). https://doi.org/10.15951/j.tmgcxb.1993.01.001

Li CX, He J, Dong CW, et al., 2015. Control of self-adaptive unstressed configuration for incrementally launched girder bridges. Journal of Bridge Engineering, 20(10): 04014105. https://doi.org/10.1061/(ASCE)BE.1943-5592.0000709

Li Q, Bu YZ, Zhang QH, 2009. Whole-procedure adaptive construction control system based on geometry control method. China Civil Engineering Journal, 42(7):69–77 (in Chinese).

Lin JP, Wang JF, Chen CL, et al., 2014. Geometric shape control of trough steel girder composite bridge constructed by incremental launching method. Bridge Construction, 44(4):102–106 (in Chinese).

Lin YP, 1983. Application of Kalman’s filtering method to cable stayed bridge construction. China Civil Engineering Journal, 16(3):7–14 (in Chinese). https://doi.org/10.15951/j.tmgcxb.1983.03.002

Meng FC, Liu MH, Wu WS, et al., 2014. The design philosophy and bridge’s technical innovation of Hong Kong-Zhuhai-Macau Bridge. Engineering Sciences, 17(1): 27–35 (in Chinese). https://doi.org/10.3969/j.issn.1009-1742.2015.01.004

Muller J, 1975. Ten years of experience in precast segmental construction. PCI Journal, 20(1):28–61. https://doi.org/10.15554/pcij.01011975.28.61

Rosignoli M, 1997. Solution of the continuous beam in launched bridges. Proceedings of the Institution of Civil Engineers-Structures and Buildings, 122(4):390–398. https://doi.org/10.1680/istbu.1997.29828

Seki F, Tanaka S, 1991. Construction control system for cable-stayed bridges. Proceedings of IABSE, 64:286–287. http://doi.org/10.5169/seals-49315

Taylor PR, 1986. Annacis bridge superstructure-a major composite cable-stayed bridge. Annual Conference RTAC, p.89–105.

Thomson WT, 1950. Matrix solution for the vibration of non-uniform beams. Journal of Applied Mechanics, 17: 337–339.

Wada K, Takano H, Tomita N, et al., 1991. Construction of the Yokohama Bay Bridge superstructure. IABSE Symposium Leningrad, 64:177–182. http://doi.org/10.5169/seals-49293

Wang JF, Lin JP, Xu RQ, 2015. Incremental launching construction control of long multispan composite bridges. Journal of Bridge Engineering, 20(11):04015006. https://doi.org/10.1061/(ASCE)BE.1943-5592.0000737

Yan DH, Chen CS, Dong DF, et al., 2012. Control of self-adaptive zero-stress configuration for long-span cable-stayed bridge with steel main girders. China Journal of Highway and Transport, 25(1):55–58 (in Chinese). https://doi.org/10.19721/j.cnki.1001-7372.2012.01.009

Zhong WX, Liu YF, Ji Z, 1992. Control and adjustment of cable tension in the construction of cable-stayed bridge. China Civil Engineering Journal, 25(3):9–15 (in Chinese).

Arici M, Granata MF, 2007. Analysis of curved incrementally launched box concrete bridges using the Transfer Matrix Method. Bridge Structures, 3(3-4):165–181. https://doi.org/10.1080/15732480701510445

Breen JE, 1985. Controlling twist in precast segmental concrete bridges. PCI Journal, 30(4):86–111. https://doi.org/10.15554/pcij.07011985.86.111

Chen DW, Zheng XG, Xiang HF, 1993. A construction control system for P.C. cable-stayed bridges. China Civil Engineering Journal, 26(1):1–11 (in Chinese). https://doi.org/10.15951/j.tmgcxb.1993.01.001

Li CX, He J, Dong CW, et al., 2015. Control of self-adaptive unstressed configuration for incrementally launched girder bridges. Journal of Bridge Engineering, 20(10): 04014105. https://doi.org/10.1061/(ASCE)BE.1943-5592.0000709

Li Q, Bu YZ, Zhang QH, 2009. Whole-procedure adaptive construction control system based on geometry control method. China Civil Engineering Journal, 42(7):69–77 (in Chinese).

Lin JP, Wang JF, Chen CL, et al., 2014. Geometric shape control of trough steel girder composite bridge constructed by incremental launching method. Bridge Construction, 44(4):102–106 (in Chinese).

Lin YP, 1983. Application of Kalman’s filtering method to cable stayed bridge construction. China Civil Engineering Journal, 16(3):7–14 (in Chinese). https://doi.org/10.15951/j.tmgcxb.1983.03.002

Meng FC, Liu MH, Wu WS, et al., 2014. The design philosophy and bridge’s technical innovation of Hong Kong-Zhuhai-Macau Bridge. Engineering Sciences, 17(1): 27–35 (in Chinese). https://doi.org/10.3969/j.issn.1009-1742.2015.01.004

Muller J, 1975. Ten years of experience in precast segmental construction. PCI Journal, 20(1):28–61. https://doi.org/10.15554/pcij.01011975.28.61

Rosignoli M, 1997. Solution of the continuous beam in launched bridges. Proceedings of the Institution of Civil Engineers-Structures and Buildings, 122(4):390–398. https://doi.org/10.1680/istbu.1997.29828

Seki F, Tanaka S, 1991. Construction control system for cable-stayed bridges. Proceedings of IABSE, 64:286–287. http://doi.org/10.5169/seals-49315

Taylor PR, 1986. Annacis bridge superstructure-a major composite cable-stayed bridge. Annual Conference RTAC, p.89–105.

Thomson WT, 1950. Matrix solution for the vibration of non-uniform beams. Journal of Applied Mechanics, 17: 337–339.

Wada K, Takano H, Tomita N, et al., 1991. Construction of the Yokohama Bay Bridge superstructure. IABSE Symposium Leningrad, 64:177–182. http://doi.org/10.5169/seals-49293

Wang JF, Lin JP, Xu RQ, 2015. Incremental launching construction control of long multispan composite bridges. Journal of Bridge Engineering, 20(11):04015006. https://doi.org/10.1061/(ASCE)BE.1943-5592.0000737

Yan DH, Chen CS, Dong DF, et al., 2012. Control of self-adaptive zero-stress configuration for long-span cable-stayed bridge with steel main girders. China Journal of Highway and Transport, 25(1):55–58 (in Chinese). https://doi.org/10.19721/j.cnki.1001-7372.2012.01.009

Zhong WX, Liu YF, Ji Z, 1992. Control and adjustment of cable tension in the construction of cable-stayed bridge. China Civil Engineering Journal, 25(3):9–15 (in Chinese).

Author information

Authors and Affiliations

Contributions

Jin-feng WANG provided the idea. Hua-wei XIANG wrote the manuscript. Jiang-tao ZHANG and Tian-mei WU helped to process the corresponding data. Rong-qiao XU helped to revise the final version.

Corresponding author

Additional information

Conflict of interest

Jin-feng WANG, Hua-wei XIANG, Jiang-tao ZHANG, Tian-mei WU, and Rong-qiao XU declare that they have no conflict of interest}.

Project supported by the Zhejiang Provincial Natural Science Foundation of China (No. LZ16E080001) and the National Natural Science Foundation of China (Nos. 51578496 and 51878603)

Rights and permissions

About this article

Cite this article

Wang, Jf., Xiang, Hw., Zhang, Jt. et al. Geometric state transfer method for construction control of a large-segment steel box girder with hoisting installation. J. Zhejiang Univ. Sci. A 21, 382–391 (2020). https://doi.org/10.1631/jzus.A1900213

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1631/jzus.A1900213