Abstract

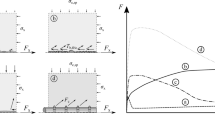

Carbon-nanotube shaped reinforcement (CSR) and traditional latitude and longitude reinforcement (LLR) made of tough resin were 3D printed and applied to concrete specimens. The element numbers of 10, 12, and 14 per layer were selected to investigate the reinforcement by CSR and LLR separately. The uniaxial compressive behaviors of the CSR and LLR reinforced concrete specimens were studied by a series of laboratory tests. The experimental results indicate that the strength of a CSR reinforced specimen with 10, 12, and 14 elements per layer increases by 59.77%, 85.94%, and 108.98%, respectively, compared with the unreinforced specimen. The strength of the LLR reinforced specimen with 10, 12, and 14 elements per layer increases by 24.22%, 46.88%, and 68.75%, respectively, compared with the unreinforced specimen. CSR thus demonstrates higher efficiency in compressive strength improvement than LLR does. The results also show that the failure pattern changes from global failure to partial failure as the element number per layer of CSR increases. The present research provides a potential innovative reinforcing technology for civil engineering applications.

概要

目 的

研究3D 打印仿碳纳米管加筋结构对混凝土单轴 受压力学性能的加固机制。

创新点

提出一种采用仿碳纳米管加筋结构对混凝土进行 加固的方法。

方 法

1. 以韧性树脂为材料,采用光固化3D 打印技术 分别制作疏密度为每层10 个单元、12 个单元和14 个单元的仿碳纳米管加筋结构和传统纵横加 筋结构。2. 将配制的M2.5 水泥砂浆作为填充材 料,制备直径为100 mm、高为200 mm 的圆柱型 单轴压缩试件。3. 以相同尺寸内部无加筋的素混 凝土试件作为参考进行抗压试验。

结 论

1. 与素混凝土相比,当试件采用每层10 个单元、 12 个单元和14 个单元的仿碳纳米管加筋结构时, 混凝土试件抗压强度分别提高59.77%、85.94% 和108.98%。2. 当试件采用每层10 个单元、12 个单元和14 个单元的传统纵横加筋结构时,混 凝土试件抗压强度分别提高24.22%、46.88%和 68.75%。3. 仿碳纳米管加筋结构对混凝土的加固 效果明显优于传统纵横加筋结构。4. 仿碳纳米管 加筋后试件的破坏形式随着加筋密度的增加由 整体破坏转变为局部破坏。

Similar content being viewed by others

References

Ahmed SFU, Maalej M, 2009. Tensile strain hardening behaviour of hybrid steel-polyethylene fibre reinforced cementitious composites. Construction and Building Materials, 23(1):96–106. https://doi.org/10.1016/jxonbuildmat.2008.01.009

Ajayan PM, 1999. Nanotubes from carbon. Chemical Reviews, 99(7): 1787–1800. https://doi.org/10.1021/cr970102g

Carballosa P, Garcia Calvo JG, Revuelta D, et al., 2015. Influence of cement and expansive additive types in the performance of self-stressing and self-compacting concretes for structural elements. Construction and Building Materials, 93:223–229. https://doi.org/10.1016/j.conbuildmat.2015.05.113

Cesaretti G, Dini E, de Kestelier X, et al, 2014. Building components for an outpost on the Lunar soil by means of a novel 3D printing technology. Acta Astronautica, 93:430–450. https://doi.org/10.1016/j.actaastro.2013.07.034

Chen SJ, Duan WH, Li ZJ, et al., 2015. New approach for characterisation of mechanical properties of cement paste at micrometre scale. Materials & Design, 87:992–995. https://doi.org/10.1016/j.matdes.2015.08.101

Chi Y, Xu LH, Zhang YY, 2014. Experimental study onhybrid fiber-reinforced concrete subjected to uniaxial compression. Journal of Materials in Civil Engineering, 26(2): 211–218. https://doi.org/10.1061/(ASCE)MT.1943-5533.0000764

Chuah S, Duan WH, Pan Z, et al, 2016. The properties of fly ash based geopolymer mortars made with dune sand. Materials & Design, 92:571–578. https://doi.org/10.1016/j.matdes.2015.12.070

Dias DP, Thaumaturgo C, 2005. Fracture toughness of geo-polymeric concretes reinforced with basalt fibers. Cement and Concrete Composites, 27(1):49–54. https://doi.org/10.1016/j.cemconcomp.2004.02.044

Fan LF, Wu ZJ, Wan Z, et al., 2017. Experimental investigation of thermal effects on dynamic behavior of granite. Applied Thermal Engineering, 125:94–103. https://doi.org/10.1016/j.applthermaleng.2017.07.007

Jiang JY, Sun W, Zhang YS, et al., 2008. Cracking resistance performance of super vertical-distance pumped SFRC. Frontiers of Architecture and Civil Engineering in China, 2(2): 179–183. https://doi.org/10.1007/sll709-008-0018-6

Jiang YJ, Fan LF, 2013. An investigation of mechanical behavior of cement-stabilized crushed rock material using different compaction methods. Construction and Building Materials, 48:508–515. https://doi.org/10.1016/j.conbuildmat.2013.07.017

Jiang YJ, Fan LF, 2015. An experimental investigation of optimal asphalt-aggregate ratio for different compaction methods. Construction and Building Materials, 91:111–115. https://doi.org/10.1016/j.conbuildmat.2015.05.054

Le TT, Austin SA, Lim S, et al., 2012. Hardened properties of high-performance printing concrete. Cement and Concrete Research, 42(3): 558–566. https://doi.org/10.1016/j.cemconres.2011.12.003

Lee YH, Kim SG, Tomanek D, 1997. Catalytic growth of single-wall carbon nanotubes: an ab initio study. Physical Review Letters, 78(12):2393–2396. https://doi.org/10.1103/PhysRevLett.78.2393

Lin XS, Zhang YX, Hazell PJ, 2014. Modelling the response of reinforced concrete panels under blast loading. Materials & Design, 56:620–628. https://doi.org/10.1016/j.matdes.2013.11.069

Lu DC, Zhou X, Du XL, et al., 2019. A 3D fractional elasto-plastic constitutive model for concrete material. International Journal of Solids and Structures, 165:160–175. https://doi.org/10.1016/j.ijsolstr.2019.02.004

Micelli F, Nanni A, 2004. Durability of FRP rods for concrete structures. Construction and Building Materials, 18(7): 491–503. https://doi.org/10.1016/j.conbuildmat.2004.04.012

Michalski MH, Ross JS, 2014. The shape of things to come: 3D printing in medicine. JAMA, 312(21):2213–2214. https://doi.org/10.1001/jama.2014.9542

MOC (Ministry of Construction of the People’s Republic of China), 2003. Standard for Test Method of Mechanical Properties on Ordinary Concrete, GB/T 50081-2002. National Standards of the People’s Republic of China (in Chinese).

MOC (Ministry of Construction of the People’s Republic of China), 2009. Standard for Test Method of Basic Properties of Construction Mortar, JGJ/T 70-2009. Industry Standards of the People’s Republic of China (in Chinese).

MOHURD (Ministry of Housing and Urban-Rural Development of the People’s Republic of China), 2010a. Code for Design of Concrete Structures, GB 500102010. National Standards of the People’s Republic of China (in Chinese).

MOHURD (Ministry of Housing and Urban-Rural Development of the People’s Republic of China), 2010b. Specification for Mix Proportion Design of Masonry Mortar, JGJ/T 98-2010. Industry Standards of the People’s Republic of China (in Chinese).

Ouyang XP, Qiu XQ, Chen P, 2006. Physicochemical characterization of calcium lignosulfonate-a potentially useful water reducer. Colloids and Surfaces A: Physico-chemical and Engineering Aspects, 282–283:489–497. https://doi.org/10.1016/jxolsurfa.2005.12.020

Pegna J, 1997. Exploratory investigation of solid freeform construction. Automation in Construction, 5(5):427–437. https://doi.org/10.1016/S0926-5805(96)00166-5

Pendhari SS, Kant T, Desai YM, 2008. Application of polymer composites in civil construction: a general review. Composite Structures, 84(2): 114–124. https://doi.org/10.1016/j.compstruct.2007.06.007

Salvetat JP, Bonard JM, Thomson NH, et al., 1999. Mechanical properties of carbon nanotubes. Applied Physics A, 69(3):255–260. https://doi.org/10.1007/s003390050999

Sanz-Izquierdo B, Parker EA, 2013. 3D printing technique for fabrication of frequency selective structures for built environment. Electronics Letters, 49(18): 1117–1118. https://doi.org/10.1049/el.2013.2256

Treacy MMJ, Ebbesen TW, Gibson JM, 1996. Exceptionally high Young’s modulus observed for individual carbon nanotubes. Nature, 381(6584):678–680. https://doi.org/10.1038/381678a0

Tsonos AG, 2008. Effectiveness of CFRP-jackets and RC-jackets in post-earthquake and pre-earthquake retrofitting of beam-column subassemblages. Engineering Structures, 30(3): 777–793. https://doi.org/10.1016/j.engstruct.2007.05.008

Walters P, Davies K, 2010. 3D printing for artists: research and creative practice. Rapport: Journal of the Norwegian Print Association, 1:12–15.

Wang GS, Lu DC, Du XL, et al, 2018. A true 3D frictional hardening elastoplastic constitutive model of concrete based on a unified hardening/softening function. Journal of the Mechanics and Physics of Solids, 119:250–273. https://doi.org/10.1016/jjmps.2018.06.019

Wight RG, Green MF, Erki MA, 2001. Prestressed FRP sheets for poststrengthening reinforced concrete beams. Journal of Composites for Construction, 5(4):214–220. https://doi.org/10.1061/(ASCE)1090-0268(2001)5:4(214)

Wong EW, Sheehan PE, Lieber CM, 1997. Nanobeam mechanics: elasticity, strength, and toughness of nanorods and nanotubes. Science, 277(5334):1971–1975. https://doi.org/10.1126/science.277.5334.1971

Wu W, Zhang WD, Ma GW, 2010a. Mechanical properties of copper slag reinforced concrete under dynamic compression. Construction and Building Materials, 24(6):910–917. https://doi.org/10.1016/j.conbuildmat.2009.12.001

Wu W, Zhang WD, Ma GW, 2010b. Optimum content of copper slag as a fine aggregate in high strength concrete. Materials & Design, 31(6):2878–2883. https://doi.org/10.1016/j.matdes.2009.12.037

Zhang YX, Zhu Y, 2010. A new shear-flexible FRP-reinforced concrete slab element. Composite Structures, 92(3): 730–735. https://doi.org/10.1016/j.compstruct.2009.09.013

Author information

Authors and Affiliations

Corresponding author

Additional information

Contributors

Li-feng FAN conducted the investigation process. Li-juan WANG revised and edited the final version. Guo-wei MA formulated the overarching research goals and aims. Peng-fei LI took the responsibility for the research activity planning and execution. Ming-jie XIA wrote the first draft of the manuscript.

Conflict of interest

Li-feng FAN, Li-juan WANG, Guo-wei MA, Peng-fei LI, and Ming-jie XIA declare that they have no conflict of interest.

Project supported by the National Natural Science Foundation of China (No. 51627812)

Prof. Li-feng FAN has been a member of the editorial board of Journal of Zhejiang University-SCIENCE A (Applied Physics & Engineering) since 2018. He is a professor of Beijing University of Technology, China. Prof. FAN received his bachelor and master degrees from Xi’an Jiaotong University, China in 2003 and 2006, respectively, and PhD degree from Nanyang Technology University, Singapore in 2012.

Prof. FAN was honored as “Young Yangtze River Scholar” (Ministry of Education) and “Great Wall Scholar” (Beijing) in 2017. He is a committee member of “Rock Dynamics Commission” and “Rock Mechanics Educational Commission” of Chinese Society for Rock Mechanics & Engineering. He was also the co-chair of the 14th International Conference on Analysis of Discontinuous Deformation.

Rights and permissions

About this article

Cite this article

Fan, Lf., Wang, Lj., Ma, Gw. et al. Enhanced compressive performance of concrete via 3D-printing reinforcement. J. Zhejiang Univ. Sci. A 20, 675–684 (2019). https://doi.org/10.1631/jzus.A1900135

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1631/jzus.A1900135

Keywords

- 3D-printing

- Carbon-nanotube shaped reinforcement (CSR)

- Latitude and longitude reinforcement (LLR)

- Rein forced concrete