Abstract

In this paper, we present a method for the global optimization of the tooth contact pattern and transmission error of spiral bevel and hypoid gears, which includes three optimization objectives, three control parameters, and a complex-constrain genetic algorithm solving method. A new set of fundamental equations for pitch cone parameters of hypoid gear drives are established, as well as the relationships between pitch cone and curvature parameters. Based on this theory, three control parameters are selected to determine the pinion tooth surface. A hypoid gear drive is chosen for case studies. The results verify that the optimization methodology can achieve the expected optimization objectives and has good convergence. Correlations between optimization objectives and control parameters are discussed. Furthermore, a finite element model of a simplified hypoid gear drive system is established and its quasi-static meshing characteristics analyzed. The results again confirm the correctness of the optimization method. The effects of torque load on the contact pattern and transmission error are discussed. The results provide a theoretical reference for geometric calculations, quasi-static analysis, and optimal design of spiral bevel and hypoid gears.

中文概要

目 的

传统的齿面接触分析技术存在调整参数繁多、控 制目标不明确和不包含传动误差优化等缺陷。本文旨在提出一种齿面接触区和传动误差的全局 优化设计方法, 以得到满足齿轮传动性能要求的 小轮产形轮节锥参数及机床调整参数。

创新点

1. 提出了新的确定各节锥参数之间几何关系的计 算公式, 并建立了节锥参数与曲率参数的相关公 式; 2. 提出以齿面接触区长半轴、接触线方向角 和传动误差曲线交点纵坐标为优化目标, 以齿面 法曲率和短程挠率为控制参数, 以复合形法约束 处理的遗传算法为求解途径的齿面接触特性全 局优化设计方法。

方法

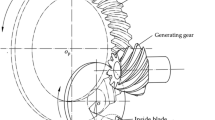

1. 分析常见齿面接触区和传动误差曲线的缺陷及 其原因(图1);2. 提出全局优化目标(图2), 进行节锥参数和曲率参数分析, 从而确定控制参 数(图3~6), 建立优化方程并进行求解算法分析 (图7 和8), 然后进行实例计算分析(图9 和10); 3. 建立齿轮副传动系统有限元分析模型, 验证优 化方法的正确性(图11~13)。

结论

1.优化设计的实例分析表明, 优化目标、控制参 数和优化算法具有良好的匹配性; 2. 通过优化目 标与控制参数的相关性分析, 得出了控制参数的 影响特征; 3. 通过有限元分析验证, 优化设计结 果达到了预期的齿轮传动性能指标。

Similar content being viewed by others

References

Achtmann, J., Bär, G., 2004. Optimized bearing ellipses of hypoid gears. Journal of Mechanical Design, 125(4): 739–745. http://dx.doi.org/10.1115/1.1625403

Argyris, J., Fuentes, A., Litvin, F.L., 2002. Computerized integrated approach for design and stress analysis of spiral bevel gears. Computer Methods in Applied Mechanics and Engineering, 191(11-12):1057–1095. http://dx.doi.org/10.1016/S0045-7825(01)00316-4

Artoni, A., Bracci, A., Gabiccini, M., et al., 2008. Optimization of the loaded contact pattern in hypoid gears by automatic topography modification. Journal of Mechanical Design, 131(1): 011008. http://dx.doi.org/10.1115/1.3013844

Artoni, A., Kolivand, M., Kahraman, A., 2009. An ease-off based optimization of the loaded transmission error of hypoid gears. Journal of Mechanical Design, 132(1): 011010. http://dx.doi.org/10.1115/1.4000645

Guo, W., Mao, S., Yang, Y., et al., 2016. Optimization of cutter blade profile for face-hobbed spiral bevel gears. The International Journal of Advanced Manufacturing Technology, 85(1): 209–216. http://dx.doi.org/10.1007/s00170-015-7893-5

Litvin, F.L., Fuentes, A., 2004. Gear Geometry and Applied Theory (2nd Edition). Cambridge University Press, Cambridge, UK, p.627.

Litvin, F.L., Wang, A.G., Handschuh, R.F., 1998. Computerized generation and simulation of meshing and contact of spiral bevel gears with improved geometry. Computer Methods in Applied Mechanics and Engineering, 158(1–2): 35–64. http://dx.doi.org/10.1016/S0045-7825(97)00229-6

Litvin, F.L., Fuentes, A., Fan, Q., et al., 2002. Computerized design, simulation of meshing, and contact and stress analysis of face-milled formate generated spiral bevel gears. Mechanism and Machine Theory, 37(5): 441–459. http://dx.doi.org/10.1016/S0094-114X(01)00086-6

Litvin, F.L., Fuentes, A., Hayasaka, K., 2006. Design, manufacture, stress analysis, and experimental tests of lownoise high endurance spiral bevel gears. Mechanism and Machine Theory, 41(1): 83–118. http://dx.doi.org/10.1016/j.mechmachtheory.2005.03.001

Mermoz, E., Astoul, J., Sartor, M., et al., 2013. A new methodology to optimize spiral bevel gear topography. CIRP Annals — Manufacturing Technology, 62(1): 119–122. http://dx.doi.org/10.1016/j.cirp.2013.03.067

Shtipelman, B.A., 1978. Design and Manufacture of Hypoid Gears. John Wiley & Sons, New York, USA.

Simon, V.V., 2009a. Design and manufacture of spiral bevel gears with reduced transmission error. Journal of Mechanical Design, 131(4): 041007. http://dx.doi.org/10.1115/1.3087540

Simon, V.V., 2009b. Head-cutter for optimal tooth modifications in spiral bevel gears. Mechanism and Machine Theory, 44(7): 1420–1435. http://dx.doi.org/10.1016/j.mechmachtheory.2008.11.007

Simon, V.V., 2013. Design of face-hobbed spiral bevel gears with reduced maximum tooth contact pressure and transmission errors. Chinese Journal of Aeronautics, 26(3): 777–790. http://dx.doi.org/10.1016/j.cja.2013.05.005

Simon, V.V., 2014. Optimization of face-hobbed hypoid gears. Mechanism and Machine Theory, 77: 164–181. http://dx.doi.org/10.1016/j.mechmachtheory.2014.02.003

Vogel, O., Griewank, A., Bär, G., 2002. Direct gear tooth contact analysis for hypoid bevel gears. Computer Methods in Applied Mechanics and Engineering, 191(36): 3965–3982. http://dx.doi.org/10.1016/S0045-7825(02)00351-1

Wu, X.T., 2009. Gear Engagement Principle (2nd Edition). Xi’an Jiaotong University Press, Xi’an, China (in Chinese).

Zeng, T., 1989. Spiral Bevel Gear Design and Processing. Harbin Institute of Technology Press, Harbin, China (in Chinese).

Zhang, T.T., Huang, W., Wang, Z.G., et al., 2016. A study of airfoil parameterization, modeling, and optimization based on the computational fluid dynamics method. Journal of Zhejiang University-SCIENCE A (Applied Physics & Engineering), 17(8): 632–645. http://dx.doi.org/10.1631/jzus.A1500308

Zhuo, Y., Zhou, X., 2015. Dynamic characteristic analysis of high-speed spherical ball bearing. Journal of Mechanical Engineering, 51(5): 37–46 (in Chinese).

Author information

Authors and Affiliations

Corresponding author

Additional information

Project supported by the National Natural Science Foundation of China (No. 51275453), the Key Research Project of Lishui, China (No. 2016ZDYF15), the North Vehicle Research Institute, and Hangzhou Advance Gearbox Group Co., Ltd., China

ORCID: Yao-bin ZHUO, http://orcid.org/0000-0002-0954-9740; Xiao-jun ZHOU, http://orcid.org/0000-0003-2565-1398

Rights and permissions

About this article

Cite this article

Zhuo, Yb., Xiang, Xy., Zhou, Xj. et al. A method for the global optimization of the tooth contact pattern and transmission error of spiral bevel and hypoid gears. J. Zhejiang Univ. Sci. A 18, 377–392 (2017). https://doi.org/10.1631/jzus.A1600240

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1631/jzus.A1600240

Keywords

- Spiral bevel gear

- Tooth contacts

- Transmission error

- Optimal design

- Genetic algorithm

- Finite element analysis