Abstract

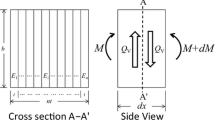

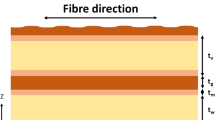

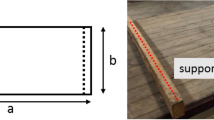

Laminated veneer lumber (LVL) is a structural composite lumber that has the advantages of uniform structure, high strength, and flexible size compared with natural solid wood. It is widely used in the timber industry. This paper aims to test the elastic constants of LVL using a dynamic method. It focuses on Populus deltoides LVL as the research subject and proposes a 1/3-span patch method of square-section cantilever beam for dynamic testing of wood Poisson’s ratio. The elastic modulus, shear modulus, and Poisson's ratio of LVL were determined through dynamic testing using the cantilever plate transient excitation method. The accuracy of the Poisson's ratio of LVL tested with the 1/3-span patch method was verified through first-order bending mode stress–strain analysis. These results were further confirmed using a static four-point bending method. The conclusion reveals that the relative error of the LVL Poisson's ratio obtained using the 1/3-span patch method for cantilever beams and the first-order bending mode method for cantilever plates (\({\sigma }_{y}\)=0 patch method) testing is 2%. The longitudinal and transverse Poisson's ratios of LVL tested with the 1/3-span patch method for cantilever beams match those obtained through the first-order bending mode method for cantilever plates and the four-point bending method. The relative error between LVL longitudinal and transverse dynamic beam elastic modulus test values and static four-point bending test values is no more than 5%. The relative error between LVL longitudinal shear modulus dynamic and static test values is 4.8%, and the results are consistent. In conclusion, the dynamic method is effective for testing the longitudinal and transverse Poisson's ratio, elastic modulus, and shear modulus of LVL. It is also more convenient than the static test method.

Similar content being viewed by others

References

Chang SY, Xing D, Wang XM et al (2020) Research progress on productive technology and properties of laminated veneer lumber. China For Prod Ind 57(7):9-11 38. https://doi.org/10.19531/j.issn1001-5299.202007003

Chen ZX, Lei Q, He RL et al (2016) Review on antibacterial biocomposites of structural laminated veneer lumber. Saudi J Biol Sci 23(1):S142–S147. https://doi.org/10.1016/j.sjbs.2015.09.025

Hakkarainen J (2020) LVL Handbook Europe. Federation of the Finnish Woodworking Industries, Finland.

Jiang HC, Li N, Tang XM et al (2011) The application of response surface methodology in process of eucalyptus LVL. Eucalyptus Sci Technol 28(1):1–8

Hassanieh A, Valipour HR, Bradford MA (2016) Experimental and numerical study of steel-timber composite (STC) beams. J Constr Steel Res 122:367–378. https://doi.org/10.1016/j.jcsr.2016.04.005

Khorsandnia N, Valipour HR, Crews K (2012) Experimental and analytical investigation of short-term behavior of LVL-concrete composite connections and beams. Const Build Mater 37:229–238. https://doi.org/10.1016/j.conbuildmat.2012.07.022

Zhang C, Zheng XZ, Lam F (2023) Development of composite action in a new long-span timber composite floor: full-scale experiment and analytical approach. Eng Struct 279:115550. https://doi.org/10.1016/j.engstruct.2022.115550

Wang X, Zhang JL, Wu P, Li YS (2022) Experimental investigation on the flexural and shear behaviour of LVL I-beam strengthened with steel channels. Constr Build Mater 341:127719. https://doi.org/10.1016/j.conbuildmat.2022.127719

Romero A, Yang J, Hanus F, Odenbreit C (2022) Numerical investigation of steel-LVL timber composite beams. ce/papers 5:21–30. https://doi.org/10.1002/cepa.1694

Chybiński M, Polus Ł (2019) Theoretical, experimental and numerical study of aluminum-timber composite beams with screwed connections. Constr Build Mater 226:317–330. https://doi.org/10.1016/j.conbuildmat.2019.07.101

Chiniforush AA, Akbarnezhad A, Valipour H, Malekmohammadi S (2019) Moisture and temperature induced swelling/shrinkage of softwood and hardwood glulam and LVL: An experimental study. Constr Build Mater 207:70–83. https://doi.org/10.1016/j.conbuildmat.2019.02.114

Bakalarz M, Kossakowski PG (2019) Mechanical properties of laminated veneer lumber beams strengthened with CFRP sheets. Arch Civ Eng 65(2):57–66. https://doi.org/10.2478/ace-2019-0018

Purba CYC, Pot G, Viguier J, Ruelle J, Denaud L (2019) The influence of veneer thickness and knot proportion on the mechanical properties of laminated veneer lumber (LVL) made from secondary quality hardwood. Eur J Wood Prod 77:393–404. https://doi.org/10.1007/s00107-019-01400-3

Chybiński M, Polus Ł (2021) Experimental and numerical investigations of laminated veneer lumber panels. Arch Civ Eng 67:351–372. https://doi.org/10.24425/ace.2021.138060

Li M, He M, Li Z (2023) Size effects on the bending strength of Chinese larch pine laminated veneer lumber. Eur J Wood Prod 81:1211–1222. https://doi.org/10.1007/s00107-023-01933-8

Zuo KH, Xu WB, Li XY et al (2021) Research status and development of laminated veneer lumber and its digital simulation. China For Prod Ind 58(1):15–19. https://doi.org/10.19531/j.issn1001-5299.202101004

Xu YW, Hou LD (2023) Development on polyacrylonitrile-based carbon fiber reinforced structural eucalyptus laminated veneer lumber. J For Eng 8(4):59–65. https://doi.org/10.13360/j.issn.2096-1359.202210023

Chen MW, Zheng X, Li XG et al (2023) Preparation and properties of Eucalyptus laminated veneer lumber using waterborne epoxy resin. China For Prod Ind 60(4):1–7. https://doi.org/10.19531/j.issn1001-5299.202304001

SLIKER A, (1989) Measurement of the smaller Poisson’s rations and related compliance for wood. Wood Fiber Sci 21(3):252–262

Gong M (1995) A study of wood elastic parameters parallel to grain in compression test by using resistance strain gages. Scientia Silvae Sinicae 31(2):189–192

Bach L, Porter AW (1988) U.S. Patent No. 4,722,223. Washington, DC: U.S. Patent and Trademark Office

Coppens H (1988) Quality control of particleboards by means of their oscillation behavior. In Proceedings of the FESYP Technical Conference, Munich, Germany, 25–26

Wang ZH, Hawi P, Masri S et al (2023) Roger Ghanem, Stochastic multiscale modeling for quantifying statistical and model errors with application to composite materials. Reliab Eng Syst Safe 235:109213

Wang ZH, Ghanem R (2021) An extended polynomial chaos expansion for PDF characterization and variation with aleatory and epistemic uncertainties. Comput Method Appl M 382:113854. https://doi.org/10.1016/j.cma.2021.113854

Wang ZH, Ghanem R (2022) A functional global sensitivity measure and efficient reliability sensitivity analysis with respect to statistical parameters. Comput Method Appl M. https://doi.org/10.1016/j.cma.2022.115175

Peng YB, Wang ZH, Ai XQ (2018) Wind-induced fragility assessment of urban trees with structural uncertainties. Wind Struct 26(1):45–56. https://doi.org/10.12989/was.2018.26.1.045

Thomas WH (2003) Poisson’s ratios of an oriented strand. Wood Sci Technol 37:259–268. https://doi.org/10.1007/s00226-003-0171-y

Gao Z, Zhang X, Wang Y, Yang R, Wang G, Wang Z (2016) Measurement of the Poisson’s ratio of materials based on the bending mode of the cantilever plate. BioResources 11(3):5703–5721. https://doi.org/10.15376/biores.11.3.5703-5721

Wang Z, Gao ZZ, Wang YL, et al (2016) Dynamic measuring Poisson’s ratio \({\mu }_{LT}\), \({\mu }_{LR}\) and \({\mu }_{RT}\) of lumbers by electrical method. Scientia Silvae Sinicae 52(8):104-114. https://doi.org/10.11707/j.1001-7488.20160813

Wang Z, Xie WB, Wang ZH, Cao Y (2018) Strain method for synchronous dynamic measurement of elastic, shear modulus and Poisson’s ratio of wood and wood composites. Constr Build Mater 182:608–619

Wang Z, Gu LL, Gao ZZ et al (2015) Experimental study on Poisson’s ratio of lumber by dynamic testing. Scientia Silvae Sinicae 51(5):102–107. https://doi.org/10.11707/j.10017488.20150512

Zhou ZR, Zhao MC, Wang Z et al (2014) Correlations of the modulus of elasticity among poplar log, veneer and LVL based on the stress wave method. J Northw For Univ 29(3):188–193

Yin SC (1996) Wood science. China Forestry Publishing House, China

Wang ZH, Wang YL, Cao Y et al (2016) Measurement of shear modulus of materials based on the torsional mode of cantilever plate. Constr Build Mater 124:1059–1071. https://doi.org/10.1016/j.conbuildmat.2016.08.104

Wang Z, Cao Y, Wang YL et al (2017) Testing shear modulus of materials based on torsional mode of cantilever plate. Scientia Silvae Sinicae 53(8):101–112. https://doi.org/10.11707/j.1001-7488.20170812

Brancheriau L, Bailleres H, Guitard D (2022) Comparison between modulus of elasticity values calculated using 3 and 4 point bending tests on wooden samples. Wood Sci Technol 36(5):367–383. https://doi.org/10.1007/s00226-002-0147-3

Wang Z, Gu XY, Mohrmann S et al (2023) Study on the four-point bending beam method to improve the testing accuracy for the elastic constants of wood. Eur J Wood Wood Prod 81(6):1375–1385. https://doi.org/10.1007/s00107-023-01955-2

Author information

Authors and Affiliations

Contributions

Dong Zhang: Conceptualization; Methodology; Visualization; Writing—original draft; Writing—review & editing. Zheng Wang: Funding acquisition; Resources; Supervision; Writing—review & editing. Hazrat Bilal: Writing—review & editing. Zhaoyu Shen: Methodology; Writing—review & editing. Yuhao Zhou: Methodology; Writing—review & editing.

Corresponding author

Ethics declarations

Conflict of interest

All author declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, D., Wang, Z., Bilal, H. et al. Study on elastic constants of laminated veneer lumber by dynamic test. Mater Struct 57, 98 (2024). https://doi.org/10.1617/s11527-024-02364-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-024-02364-4