Abstract

Owing to their ability to form buffer solutions, the attack of organic acids on concrete structural components can be highly aggressive. This work considers the changes in microstructure, chemical and phase composition in hardened Portland cement paste (hcp) exposed to acetic acid/sodium acetate or citric acid/sodium citrate buffer solutions. The degradation products were investigated using 29Si and 27Al NMR spectroscopy with XRD and ICP-OES. Exposure to acetic acid/sodium acetate at pH 3.9 ≤ pH ≤ 5.5 decalcifies hcp to produce aluminosilica gels (0.1 ≤ Al/Si ≤ 0.3) with Si predominately in Q3/Q4 sites and NBO values (non-bridging oxygen per Si atom) 0.6 ≤ NBO ≤ 0.9. Cross-linking processes causing the formation of the gel from C–A–S–H dreierketten incorporate Al, originally in crystalline phases and C–A–S–H phases. Degradation by citric acid/sodium citrate is governed by the precipitation of expansive calcium citrate which continuously removes degraded surface material. Pore-blocking at the degradation front inhibits acid transport deeper into the material. A new mathematical expression is presented which enables the calculation of NBO for aluminosilica gels of known Al/Si ratio from 29Si NMR spectra despite overlapping signals. The expression was verified by a stochastic computer model based on a Si quartz lattice with substituted Al and vacancies. The model simulated the measured 29Si NMR spectra of aluminosilica gels.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Concrete structural components in agriculture such as containers for liquid manure, silage, biomass for methane production as well as vessels for waste products in the dairy industry can be exposed to a variety of organic acids (e.g. acetic, citric, lactic) during their service life. Reviews published by Bertron and Duchesne [1] and, more recently, Ninan et al. [2] consider the acids present in different manufacturing processes and their action on cementitious materials. Acid attack results in the dissolution of the hardened binder paste matrix and, if soluble, the aggregate to form a degraded surface layer that increases in thickness as time passes if fresh acid is continuously supplied to the concrete surface, see [3]. Since the degraded layer is highly porous and possesses virtually no mechanical strength, the cross-section of the concrete components is reduced in effect. The acid may also induce reinforcement corrosion. Buffer solutions of weak organic acids are known to be particularly aggressive, e.g. degradation depths of 5 mm in concrete can be reached by acetic acid/sodium acetate buffer solutions after just 20 days despite a relatively high pH of 4.5 [4]. As well as shortening service life and increasing expenditure for renewal or maintenance, degradation caused by organic acid attack is ecologically disadvantageous regarding the conservation of resources and the reduction of CO2 emissions.

The effect of concrete composition on the rate of degradation is often assessed by immersing concrete specimens in acid solutions and maintaining pH by the periodic addition of acid or renewal of the storage medium, e.g. [5, 6]. Sometimes the specimens are brushed to simulate abrasion, e.g. [6]. Performance is typically related to loss of mass, strength, and visual degradation. Recently, Scherer et al. [7] used such a procedure to investigate resistance to acetic and lactic acids. The effect of citric acid on hardened binder paste prisms (10 and 50 mm cubes) was also investigated in this manner by Damion et al. [8].

Since the rate of degradation is governed primarily by the dissolution and precipitation of phases, i.e. solubility equilibria, in the hardened binder matrix in the presence of acid, Berger et al. [9] stored ground hardened binder pastes in acetic acid solutions with a range of concentrations until equilibrium conditions were virtually reached. It was thus possible to relate pH and calcium dissolution and, using thermodynamic modelling, phase changes to the amount of acid added. In the present investigations, thin hardened Portland cement paste disks were immersed in buffer solutions to minimize pH changes during storage while reducing the effect of transport processes through the degraded surface layer to the remaining undamaged material.

Depending on the pH of the acid and its type, zones of different mineralogical composition have often been observed during degradation [10, 11]. Since the OH− concentration in the pore solution of the undamaged material is many orders of magnitude higher than the proton concentration in the reaction zone of the acid, the acid protons are mainly neutralized at the degraded layer/undamaged concrete interface, i.e. at the degradation front where a sharp change in pH occurs [12,13,14,15]. As degradation proceeds, first portlandite dissolves transferring calcium ions to the pore solution. A solution-filled space is produced thus increasing porosity. At the same time, porosity can be reduced by the precipitation of the corresponding calcium salt of the acid depending on its solubility [15]. However, this does not necessarily improve acid resistance because an expansive precipitate can cause disintegration of the otherwise protective degraded layer, e.g. [16].

Once portlandite depletes, the pH of the pore solution falls below about 12.4 and AFm and AFt dissolve. At pH below about 10 decalcification of the calcium silicate hydrate phases (C–S–H) takes place causing a substantial decrease in mechanical strength and a further increase in porosity. Acid attack is often characterized by a light-brown discoloration at the degradation front which is due to the precipitation of ferric hydroxide from iron formerly contained in solid phases [10, 13]. The exchange of calcium in C–S–H with acid protons separates water molecules linking the silicate chains [17, 18] until ultimately the original dreierketten C–S–H chains transform into an amorphous silica gel with a network structure. Work by Irbe [19] on the effect of decreasing pH (hydrochloric acid) on the structure of C–(A)–S–H phases (Al/Si = 0.05) shows that at first the mean chain length of the dreierketten increases near pH 9 which is then followed by the transformation of the dreierketten to the silica gel network beginning at pH 8 as cross-linking increases. The transformation is complete near pH 7.

The residual material produced by acid attack is essentially silica gel with incorporated aluminium but may also contain aluminium and iron, probably in the form of hydroxides and, depending on its solubility, the calcium salt of the acid: aluminium and iron dissolve in the acid at roughly pH < 4 and pH < 2, respectively [10, 19,20,21]. Based on storage solution analysis using ground Portland cement paste, Roosz et al. [21] calculated an Al/Si of 0.3 for alumininosilica gel formed at pH down to 4.

This paper focuses on the changes in microstructure, chemical and phase composition in hardened Portland cement paste exposed to acetic acid/sodium acetate or citric acid/sodium citrate buffer solutions. The investigations were carried out using 29Si and 27Al MAS NMR spectroscopy as well as chemical analysis (ICP-OES) and X-ray diffraction.

Since an intact degraded layer on the concrete surface protects, to certain extent, the undamaged concrete from the external acid, the properties of the degraded layer are crucial for the resistance of concrete to acid attack [4, 22]. The effect of aluminium, which is often contained in secondary cementitious materials, on the microstructure of silica gel in the degraded material is considered in detail. Thus, the last part of this paper considers the interpretation of NMR spectra for degraded hardened cement paste, i.e. aluminosilica gel, in which C–A–S–H phases are no longer present. In this case, Al/Si ratios and chain lengths cannot be calculated in the usual manner from signal intensities by assuming the dreierketten structure of C–A–S–H phases [23]. Moreover, strong overlapping of individual signal intensities occurs.

Considering the degradation of hydrated Portland cement by organic acids, this paper follows up an earlier publication [20] which dealt with degradation by hydrochloric and sulphuric acids representing mineral acids forming highly or sparingly soluble calcium salts.

2 Specimen preparation and measurements

Based on DIN EN 196–1, Portland cement CEM I 42.5 R, (20.62 wt% SiO2, 61.93 wt% CaO, 5.23 wt% Al2O3, 3.49 wt% Fe2O3, LOI 1.51 wt%: oxides in fused specimens determined using ICP-OES as described below) was blended with deionized water at a water-to-cement ratio (w/c) of 0.4. Cylindrical polyethylene vials, 30 mm in diameter, were filled with the fresh paste, vibrated and then sealed with caps. To obtain a high degree of hydration, the filled vials were stored for 90 days at 20 °C. Afterwards, the hardened cement paste cylinders were demoulded and disks, 3.00 mm in thickness, produced with a high-precision saw. The disks were then stored in a saturated calcium hydroxide solution in an airtight container until further treatment.

Buffer solutions were prepared from sodium acetate and glacial acetic acid for pH values of 3.94, 4.45 and 5.47. The amounts of solid sodium acetate and liquid acetic acid used per litre of solution were 54.43 g and 103 ml, 138.64 g and 103 ml, 450 g and 40 ml, respectively. Citric acid/sodium citrate buffer solutions with pH values of 3.95, 4.22 and 5.09 were produced from citric acid monohydrate and sodium hydroxide with amounts of 334 and 72, 339 and 79, 336 and 131 g per litre solution, respectively. The chemicals were supplied by CHEMSOLUTE. Table 1 shows the chemical compositions of the solutions.

Three disks were placed in 150 mL of each buffer solution, stirred continuously for 28 days at 22 °C, removed from the acid, dried at 40 °C, weighed and prepared for the different investigations. Parallel reference specimens, not exposed to acid, were available in the saturated calcium hydroxide solution.

Disks for each storage procedure were finely ground in isopropyl alcohol and dried at 40 °C. The material was then analysed with 29Si and 27Al MAS NMR spectroscopy which was followed by qualitative XRD analysis and finally chemical analysis with ICP-OES.

Zirconia rotors (4 and 7 mm for 29Al, and 27Si NMR, respectively) containing the dry powders were used in the NMR measurements which were carried out with a Bruker Avance 300 spectrometer (magnetic field strength 7.0455 T) in MAS mode (magic angle spinning) with the single pulse technique. The instrument settings are listed in [20, Table 1].

The Bruker WINNMR software was used to deconvolute the 29Si NMR spectra whereby the signal intensities in this paper are labelled using the Qn nomenclature according to Engelhardt and Michel [24]. In the case of the 27Al NMR, the signals are labelled, correspondingly, by qn sites.

An XRD 3003 TT diffractometer of GE Sensing & Inspection Technologies in θ-θ configuration using Cu Kα radiation (λ = 1.54 Å) measured X-ray intensities over scattering angles between 5 and 70° with steps of 0.02°. The total measuring time for each specimen was six hours.

To analyse the specimens chemically, lithium metaborate was added to the ground material (mass ratio 3:1) which was then fused for 15 min at 1000 °C. After recording the loss on ignition, the material was dissolved in 1 molar nitric acid followed by dilution with ultrapure water to 100 mL. Inductively coupled plasma optical emission spectroscopy (ICP-OES) in a HORIBA Jobin Yvon Ultima 2 ICP-OES was used to analyse the solutions.

3 Experimental results and discussion

3.1 Degradation in acetic acid/sodium acetate buffer solutions

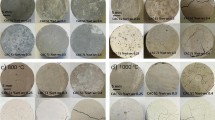

The photographs in Fig. 1 show the degraded specimens following storage in the acetic acid/sodium acetate buffer solutions for 28 d at different pH.

The chemical compositions of the degraded disks with respect to their dry weight before exposure to the acid were calculated from the ICP-OES analyses and the appropriate dry weights of the disks, Table 2.

The X-ray patterns in Fig. 2 illustrate the phase changes which occurred during the 28-day storage period.

In all cases, the specimens degraded to an amorphous material throughout their 3 mm thickness as indicated by the broad peaks near a scattering angle of 26° and the absence of the peaks observed for the reference specimen in the XRD patterns. This high degree of degradation is due to the buffer capacity of the solutions that maintained large amounts of undissociated acetic acid molecules for proton production at the degradation front thus causing a high rate of penetration of the degraded layer. Similar changes in the microstructure of harden cement paste were observed by Bertron et al. [25] who used a mixture of organic acids.

In view of thermodynamic equilibria based on experimental data by Lothenbach et al. [26], portlandite, calcite, ettringite and monosulphate are no longer thermodynamically stable at the pH considered and have thus dissolved along with the C–S–H phases to form an amorphous material and, depending on pH, gypsum.

The 29Si NMR spectra (Fig. 3) show the complete transformation of the original C–S–H phases (reference) into silica gel in which Si mainly occupies Q3 and Q4 sites. The original dreierketten chain structure of the C–S–H phases contains essentially Si end groups Q1 (bonded to one O–Si), middle groups Q2 (bonded to two O–Si) and, depending on aluminium content, Q2(1Al) (bonded to one O–Si and one O–Al). Cross-linking and destruction of the C–S–H structure is characterized by Si environments with three or four O-Si bonds, i.e. Q3 and Q4, respectively. The Q4 sites dominate towards low pH.

In the 27Al spectra, the signals peak near q4(4Si) at 55 ppm (Al linked to four O–Si) indicating that residual Al is an integral part of the silica gel network. At the relatively high pH of 5.47, the specimen consists of silica gel, but with a lower degree of networking compared with pH 4.45 and 3.94.

The chemical analysis of the degraded specimens (Table 2) reveals that the mass loss of the hardened cement paste is mainly due to calcium dissolution. The amount of sodium in the dry material increases with pH, which agrees with the sodium content of the buffer solutions in Table 1.

Surprisingly, the XRD data in Fig. 2 show that gypsum is not present at pH 5.47, whereas its amount increases towards lower pH, although calcium is expected to dissolve readily at all the pH considered. Using the Rietveld refinement, the gypsum content of the amorphous material was estimated at 6 and 14 wt% for pH 4.45 and 3.94, respectively. This behaviour agrees with the S content of the degraded determined by chemical analysis, Table 2. The S contents in Table 2 correspond to calculated gypsum contents of 4.0 and 10.3 wt% at pH 4.45 and 3.94, respectively. Thus, correcting for Ca in gypsum, the Ca contents of the silica gel are 25 and 20 mmol/100 g, respectively. Irrespective of pH, the Ca content is reduced to about 20 mmol/100 g during storage and the Ca/Si ratio is around 0.1. It is not surprising that the storage pH has little effect on the degree of decalcification because the neutralization capacity is not prescribed by pH, which defines the proton concentration, but mainly by the content of undissociated acid molecules, which, as already mentioned, is very large in the buffer solutions used.

The Al/Si ratio derived from chemical analysis of the degraded specimens in Table 2 represents that of the decalcified C–S–H phases because crystalline phases are no longer present and 27Al NMR does not reveal the presence of aluminium hydrate (at 5 ppm), cf. [20]. While most of the Al in the reference specimen is chemically bonded in AFm phases, ettringite and C–A–S–H phases (total Al/Si = 0.31), the Al/Si ratio of the resulting silica gel (0.10 to 0.27) is significantly above that of the C–A–S–H phases in the reference material, Al/Si = 0.06 (NMR value for reference specimen published in [20]). This suggests that Al dissolved from AFm and ettringite enters the silica gel structure during the restructuring of C–A–S–H as degradation proceeds. The data in Table 2 show that the Al content and therefore the Al/Si ratio of the silica gel decrease significantly with pH. The hydrated oxides of aluminium are expected to dissolve near pH 4.

During exposure of cementitious materials to acids, protons diffuse from the surface towards the degradation front where phases containing Fe dissolve and enter the pore solution. Owing to the decrease in pore solution pH over the degraded layer towards the external surface, the dissolved iron precipitates as a characteristic light-brown ferric hydroxide immediately behind the degradation front [10, 14]. Such layers of ferric hydroxide are apparent in the specimen subjected to pH 5.47 in Fig. 1. At lower pH, more ferric hydroxide is in solution which could explain the absence of these layers in the specimens stored at pH 3.94 and 4.45. Accordingly, the Fe content after pH 5.47 storage is higher than after pH 4.45 and 3.95, Table 2. This agrees with the Fe concentrations in the storage solutions which were 5 mmol/L at pH 5.47 compared with 18 and 17 mmol/L at pH 4.45 and 3.94, respectively.

According to investigations by Pokrovski et al. [27] on the hydrolysis of Fe(III) in the presence of aqueous silica, Fe(III) favours tetrahedral coordination in Fe-Si complexes at high Si concentrations (> 100 mmol/L) and may therefore be able to substitute in a silicate network. In the present work, the strong red discoloration of the storage solutions (Fig. 4, left) indicates the formation of an iron acetate complex with high solubility. Thus rather than substituting Si in the network, Fe(III) is probably present as a counterion or as Fe(OH)3 intermingled with the gel.

3.2 Degradation in citric acid/sodium citrate buffer solutions

The degradation of the disks after 28 d in citric acid/sodium citrate buffer solutions resulted in a completely different optical appearance (Fig. 4) compared with storage in acetic acid/sodium acetate buffer solutions. While the acetic acid-based buffers led to disintegration and formation of coarse particles with low strength, the citric acid/sodium citrate buffers produced thin slices of solid residual material (Fig. 5) and voluminous precipitate, visible in Fig. 4, right, at the bottom of the beakers which was chemically analysed and found to be mainly calcium citrate. Larreur-Cayol et al. [16] also observed white calcium citrate precipitate not attached to the surface of cement-based materials stored in citric acid pH 4. Ninan et al. [28] exposed Portland cement mortar cylinders to different organic acids (5, 10 and 15%) for 42 days and renewed at intervals of 7 days. The specimens stored in citric acid exhibited the largest loss of mass while producing substantial amounts of precipitate at the bottom of the storage containers. They attributed this behaviour to the tri-acidic nature of citric acid and the precipitation of expansive calcium citrate in the cement matrix.

The degree of degradation of the residual slices was obviously much lower than that of the residual material following treatment with acetic acid/sodium acetate buffer solutions. Thus, the Ca content of the residual slices after citric acid/sodium citrate storage is higher than after acetic acid/sodium acetate storage, Table 2. Moreover, the 29Si NMR spectra (Fig. 6) indicate that for all citric acid/sodium citrate pH considered, C–A–S–H dreierketten chains are still present, cf. [23].

In Fig. 6, storage in the buffer solution causes an increase in Q2 signal intensity compared with Q1 in the 29Si NMR spectra. This is due to a low degree of decalcification which caused moderate extension of the mean chain length from the initial 3.6 tetrahedra, Table 3. Significant formation of Q3 sites occurs only at pH 3.95. This agrees with the shift of the broad peak near 70 ppm (q2(2Si)), i.e. sites with Al linked to two O–Si, in the 27Al NMR spectrum to about 55 ppm (q4(4Si)). According to the observations of Irbe [19], this means that the solution equilibrium pH of C–S–H phases in the pore solution of the residual slices is near 8 because cross-linking between the dreierketten is still in progress. However, an increase in ettringite derived from AFm is evident in the 27Al spectra indicating perhaps that, based on solution equilibria, e.g. [26], the pore solution of the slices has a higher pH (> 11.1) and consequently the slices a lower degree of degradation. Based on composition profiles, Larreur-Cayol et al. [16] report the formation of zones due to citric acid attack; a decalcified transition zone with signs of amorphization at the surface of the residual material followed by a zone without portlandite, but with more ettringite, and a central zone of intact material.

The analysis of the 29Si NMR spectra of the residual material yields the percentage of Si in different sites, Table 3. The chain lengths and Al/Si ratios were determined assuming a dreierketten structure [23] and confirm that the C–S–H phases in the residual slices were not significantly modified by the acid storage.

Although the precipitate at the bottom of the beakers (Fig. 4, right) consists mainly of calcium citrate, chemical analysis revealed that it contains up to 5.5 wt% SiO2 and about 0.2 wt% Al2O3 (Al/Si ratio about 0.07). The 29Si NMR spectra (Fig. 7) show the presence of silica gel with Q3 and Q4 sites like the degradation products after mineral acid treatment at pH 2 published in [20].

The above observations are in general agreement with the results of earlier investigations with sulphuric acid [20] and gypsum as moderately soluble calcium salt. Gypsum precipitation reduces the flow of acid protons to the degradation front and is, to a certain extent, protective.

In the case of the citric acid/sodium citrate buffer solutions, the precipitation of calcium citrate, which is expansive and does not adhere to the hardened cement paste matrix, results in the destruction and removal of degraded material weakened by C–A–S–H dissolution. The surface of the residual slices corresponds to the degradation front.

As opposed to acetic acid/sodium acetate buffers, the degraded layer does not remain intact and therefore cannot provide protection for the inner material. However, the residual slices are virtually intact and mechanically stable indicating that the initial reactions at the degradation front densify the pore structure at the reaction front and reduce the transport of the acid deeper into the material. Such processes result in a pH profile with a sharp increase at the degradation front.

4 Interpretation of 29Si NMR spectra of aluminosilica gel as a degradation product

The broad 29Si NMR peaks of the aluminosilica gels formed in the acetic acid/sodium acetate buffer solutions (e.g. Figure 8, right) are the result of the considerable overlap of NMR signals from Qn and Qn+m(mAl) sites. Thus, the individual signals from such sites are no longer visible in the spectra. In this case, the gel contains a relatively large amount of Al = 0.10 and therefore deconvolution requires the inclusion of individual peaks for sites with more than one Al atom in their environment. The gels produced by the other buffer solutions possesses Al/Si up to 0.27, Table 4. In our earlier work [20] with hydrochloric acid at pH 2, the Al/Si ratio of the gel was only 0.009 and, as apparent in Fig. 8, left, the 29Si spectrum has more structure. In this case, the Q sites in the gel contain at most one Al atom.

29Si NMR spectra of aluminosilica gels including the deconvolution results. Left: due to storage in HCl at pH 2 for 28 d, Al/Si = 0.009, NBO = 0.48, taken from [20]. Right: due to storage in acetic acid/sodium acetate buffer solution at pH 3.94 for 28 d, Al/Si = 0.10, see Table 4 for values. Blue lines: measured, black lines: fitted following [30]

It is, of course, not possible to calculate the Al/Si ratio of the gels from 29Si NMR spectra according to [23] because the gel is amorphous and no longer possesses the dreierketten chain structure of C–A–S–H phases.

The gel can also be characterized by the number of non-bridging oxygen atoms (NBO), a value commonly used in glass chemistry [29]. It describes the degree of networking indicating the number of oxygen atoms in a silicate (aluminate) tetrahedron not bridging to other tetrahedra. It can be used to calculate the charge balance between the silicate network and its counterions, refer to [20] for details.

In this section, an equation has been derived which enables the calculation of NBO from the deconvolution of 29Si NMR spectra for a given Al/Si ratio from chemical analysis.

The neighbouring atoms (“chemical environment”) affect the chemical shift of the 29Si NMR signals. Each additional neighbouring Si shifts the resonance of a Si site by about 6 to 8 ppm upfield (the well-known Qn variation, [24]). Each neighbouring Al shifts the resonance by about 3 to 4 ppm downfield. The variations Qn+m(mAl) with 0 ≤ n + m ≤ 4, limited in our aluminosilica gel to 2 ≤ n + m ≤ 4 with the additional specification 0 ≤ m ≤ n leads to seven different peak positions separated by about 3 to 4 ppm because some combinations result in the same position, e.g. Q3 and Q4(2Al), as shown in Table 4.

Since the structure of the aluminosilica gel is unknown, an expression has been derived to calculate the value of NBO from the NMR data and a known Al/Si ratio. In view of the present 27Al NMR results, it is assumed that each Al atom is surrounded by on average four neighbouring Si atoms. In this case, the Al/Si would be as follows.

Obviously, this cannot be calculated for the experimental data owing to overlap. The number of non-bridging oxygen atoms per Si atom (maximum 4) is given by

and is only contributed to by sites with n + m = 2 or 3.

Owing to the overlap of the signals for the gel sites in Table 4, the signal intensity is only known for Q2(2Al), Q4(1Al) and Q4 sites, the others being unknown. If variables are assigned to the unknown intensities for Q4(2Al), Q4(3Al), Q4(4Al), Q3(2Al) and Q3(3Al), Eqs. (1–2) become the following.

Here, I refers to the measured intensity at a particular chemical shift. z contains the unknown intensities and s sums Si over the silica gel spectrum.

The above equations can be solved to yield an expression for NBO in terms of the Al/Si ratio and the signal intensities at − 105, − 101, − 96, − 92, − 88 and − 83 ppm.

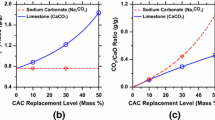

The NBO values in Table 4 were determined with the Al/Si ratio derived from the corrected chemical analysis. They show an increase in bonding between Si atoms as pH decreases.

5 Simulation of 29Si NMR spectra of aluminosilica gel

5.1 Description of the model

Owing the superposition of NMR signals as described above, the interpretation of the spectra to obtain information on the structure of the aluminosilica gel is difficult. To obtain an indication of the amount of Si in different Qn+m(mAl) sites and the effect of Al on the NMR spectra, the gel microstructure was simulated numerically in three dimensions using a stochastic computer modelling approach. To do this, a three-dimensional lattice based on the structure of quartz was set up. The lattice comprised three sublattices jlat generated with coordinates (1 + 2 m, 1 + 2 n, 2 p), (2 m, 1 + 2 n, 1 + 2 p) and (1 + 2 m, 2 n, 1 + 2 p) where the indices m, n and p run from 0 to 9, i.e. 3000 lattice positions. The side of the unit cell was set to 2 for convenience. Thus, a particular lattice position is given by the indices (jlat, m, n, p). Each lattice position possesses four nearest neighbours whose indices are found by adding 0, − 1 or 1, as appropriate, to the indices m, n, p. The nearest neighbours can be in different sublattices. Periodic boundary conditions were applied to the assembly.

The lattice positions were occupied by either Si or Al atoms or left empty (vacancies) to obtain target ratios for Al/Si and vacancy/Si. This was achieved by initially occupying all lattice positions by Si atoms which were then randomly selected and replaced with Al atoms and vacancies until the target ratios were reached. A selected Si atom was only replaced if isolated Al atoms, neighbouring Al atoms and Al atoms at the end of Si groups, i.e. q1(1Si) were not produced. This choice depended on the occupation of the neighbouring lattice positions.

Finally, the numbers of Si atoms for nearest neighbour types (Si, Al or vacant) were counted to obtain the relative intensities of the individual Qn+m(mAl) peaks. The number of non-bridging oxygen atoms per Si atom (NBO) was calculated from the simulated spectrum using Eq. (2).

5.2 Results of simulations

Model simulations were carried out by varying the input parameters Al/Si and vacancy/Si ratios to obtain a reasonable fit of the NMR spectra measured for the hardened paste stored in HCl pH 2 (Fig. 8, left, and Table 3 in [20]) and acetic acid buffer solutions pH 3.94, 4.45 and pH 5.47, Table 4. Results are shown for HCl pH 2 and acetic acid pH 5.47 in Figs. 9 and 10, respectively, in which the contributions from sites with similar chemical shifts are added according to Table 4.

Symbols label the experimental NMR spectrum for aluminosilica gel from hcp stored 28 d in HCl pH 2. Bars for simulated 29Si NMR spectrum, Al/Si = 0.009, vacancy/Si = 0.15 yielding NBO = 0.51 mol O/mol Si. The overlapping peaks are added according to Table 4 and labelled with the individual contributions displayed above the chemical shift positions

Symbols label the experimental spectrum for aluminosilica gel from hcp stored 28 d in acetic acid/sodium acetate buffer solution pH 5.47. Bars for simulated 29Si NMR spectrum, Al/Si = 0.31, vacancy/Si = 0.35 yielding NBO = 0.81. The overlapping peaks are added according to Table 4 and labelled with the individual contributions displayed above the chemical shift positions

As expected, Figs. 9 and 10 show that as more Al is incorporated in Q4 sites, the signal Q4(1Al) increases while Q4 decreases correspondingly in strength. Although more Al results in a decrease in Q3 from 33.8 to 14.3%, the total signal at − 101 ppm is significantly strengthened by the appearance of Q4(2Al). A strong new peak due to Q3(1Al) and Q4(3Al) appears at − 96 ppm between Q2 an Q3.

The validity of Eq. (7) was checked by comparing the NBO values calculated from the experimental data using Eq. (7) (Table 4) with the NBO values calculated from the corresponding simulation of the aluminosilica gel structure. In all cases, similar values were obtained.

6 Conclusions

Exposure of hydrated Portland cement disks (w/c = 0.4), 3 mm in thickness, to acetic acid/sodium acetate buffer solutions at pH 3.94, 4.45 or 5.47 resulted in complete degradation throughout specimen thickness, decalcification of the C–A–S–H phases and the formation of an aluminosilica gel with a predominantly Q3/Q4 structure rich in Al as an integral part of the gel network. The cross-linking processes causing the formation of the gel from C–A–S–H dreierketten incorporate Al, originally in crystalline phases and C–A–S–H phases, into the gel.

The broad 29Si NMR peak of Al rich aluminosilica gel produced by acetic acid/sodium acetate buffer solutions comprises many overlapping resonances from sites with one or more Al atoms in their environment. A new mathematical expression is presented which enables calculation of NBO values from such 29Si spectra for aluminosilica gels with known Al/Si ratios.

Based on chemical analysis of Al in the gels, deconvolution of the 29Si spectra and application of the new expression, the amount of Al incorporated in the gel structure and the NBO value (non-bridging oxygen atoms per Si) increase with storage pH, 3.9 ≤ pH ≤ 5.5, 0.1 ≤ Al/Si ≤ 0.3 and 0.6 ≤ NBO ≤ 0.9, respectively. Thus, the solubility of Al in the gel decreases with pH and is expected to be completely removed near pH < 3.

A stochastic computer model based on a quartz lattice, but with Si substituted by Al or vacancies, was used to simulate the aluminosilica gel structure and the corresponding 29Si NMR spectra. The model yields the different contributions from Qn+m(mAl) sites to the spectra and NBO values. The NBO values obtained from the model simulations confirm the applicability of the new mathematical expression.

The progress and degree of degradation on exposure of hydrated Portland cement disks to citric acid/sodium citrate buffer solutions differed markedly from acetic acid/sodium acetate buffers although the pH values of the buffer solutions were similar. During exposure to citric acid/sodium citrate, calcium citrate mixed with a small amount of Q3/Q4 aluminosilica gel (Al/Si ⌢0.07) precipitated in the storage medium. Since calcium citrate is expansive, complete disintegration and removal of material up to a well-defined degradation front occurred. Thin slices of undamaged material containing virtually intact C–A–S–H phases remained because pore-blocking at the degradation front inhibits the diffusion of acid deeper into the material.

References

Bertron A, Duchesne J (2007) Attack of cementitious materials by organic acids in agricultural and agrofood effluents—a review. In: Belie ND (ed) Performance of cement-based materials in aggressive aqueous environments—characterization, modelling, test methods and engineering aspects. RILEM Publications SARL, Ghent, pp 57–63

Ninan CM, Ajay A, Ramaswamy KP, Thomas AV, Bertron A (2020) A critical review on the effect of organic acids on cement-based materials. Conf Series Earth Environ Sci 491(1):012045. https://doi.org/10.1088/1755-1315/491/1/012045

Beddoe RE, Dorner HW (2005) Modelling acid attack on concrete: part I, the essential mechanisms. Cem Concr Res 35:2333–2339. https://doi.org/10.1016/j.cemconres.2005.04.002

Beddoe RE, Schmidt K (2009) Acid attack on concrete—effect of concrete composition; part 1. Cem Int 7(3):88–94

Gruyaert E, Van den Heede P, Maes M, De Belie N (2012) Investigation of the influence of blast-furnace slag on the resistance of concrete against organic acid or sulphate attack by means of accelerated degradation tests. Cem Concr Res 42:173–185. https://doi.org/10.1016/j.cemconres.2011.09.009

Madraszewski S, Sielaff AM, Stephan D (2023) Acid attack on concrete—damage zones of concrete and kinetics of damage in a simulating laboratory test method for wastewater systems. Constr Build Mater 366:130121. https://doi.org/10.1016/j.conbuildmat.2022.130121

Scherer C, de Lima LF, Zorzi JE (2023) Effect of partial replacement of cement by fine powders on the corrosion resistance of concrete. Constr Build Mater 401:132982. https://doi.org/10.1016/j.conbuildmat.2023.132982

Damion T, Cepuritis R, Chaunsali P (2022) Sulfuric acid and citric acid attack of calcium sulfoaluminate-based binders. Cem Concr Compos 130:104524. https://doi.org/10.1016/j.cemconcomp.2022.104524

Berger F, Bogner A, Hirsch A, Ukrainczyk N, Dehn F, Koenders E (2022) Thermodynamic modeling and experimental validation of acetic acid attack on hardened cement paste: effect of silica fume. Materials 15:8355. https://doi.org/10.3390/ma15238355

Pavlík V (1994) Corrosion of hardened cement paste by acetic and nitric acids, part II: formation and chemical composition of the corrosion products layer. Cem Concr Res 24:1495–1508. https://doi.org/10.1016/0008-8846(94)90164-3

Bertron A, Duchesne J, Escadeillas G (2005) Accelerated tests of hardened cement pastes alteration by organic acids: analysis of the pH effect. Cem Concr Res 35:155–166. https://doi.org/10.1016/j.cemconres.2004.09.009

Pavlík V, Unčík S (1997) The rate of corrosion of hardened cement pastes and mortars with additive of silica fume in acids. Cem Concr Res 27:1731–1745. https://doi.org/10.1016/S0008-8846(97)82702-0

Beddoe RE, Hilbig H (2008) Modelling the evolution of damage to concrete by acid attack. In: Franke L, Deckelmann G, Espinosa-Marzal R (eds) Simulation of time dependent degradation of porous materials. Final report on Priority Programme SPP1122 funded by the DFG. Cuvillier Verlag Göttingen, Hamburg, pp 275–292

Beddoe RE (2016) Modelling acid attack on concrete: part II A computer model. Cem Concr Res 88:20–35. https://doi.org/10.1016/j.cemconres.2015.10.012

Pavlík V (2019) Acid attack on hardened cement paste by acids forming low soluble calcium salts. IOP Conf Series: Mater Sci Eng 549(1):012020. https://doi.org/10.1088/1757-899X/549/1/012020

Larreur-Cayol S, Bertron A, Escadeillas G (2011) Degradation of cement-based materials by various organic acids in agro-industrial waste-waters. Cem Concr Res 41:882–892. https://doi.org/10.1016/j.cemconres.2011.04.007

Chen JJ, Thomas JJ, Taylor HFW, Jennings HM (2004) Solubility and structure of calcium silicate hydrate. Cem Concr Res 34:1499–1519. https://doi.org/10.1016/j.cemconres.2004.04.034

Haga K, Shibata M, Hironaga M, Tanaka S, Nagasaki S (2002) Silicate anion structural change in calcium silicate hydrate gel on dissolution of hydrated cement. J Nucl Sci Technol 39:540–547. https://doi.org/10.1080/18811248.2002.9715232

Irbe L (2019) Rolle des Aluminiums in C-A-S-H bei chemischem Angriff auf Beton. Technical University of Munich, Munich

Gutberlet T, Hilbig H, Beddoe RE (2015) Acid attack on hydrated cement—effect of mineral acids on the degradation process. Cem Concr Res 74:35–43. https://doi.org/10.1016/j.cemconres.2015.03.011

Roosz C, Marie Giroudon M, Lacarrière L, Lavigne MP, Patapy C, Bertron A (2024) New insights into aluminosilicate gel from acetic acid attack of hydrated Portland cement: experimental and thermodynamic characterization. J Appl Geochem 162:105923. https://doi.org/10.1016/j.apgeochem.2024.105923

Beddoe RE, Schmidt K (2009) Acid attack on concrete—effect of concrete composition; part 2. Cem Int 7(4):86–93

Andersen MD, Jakobsen HJ, Skibsted J (2004) Characterization of white portland cement hydration and the CSH structure in the presence of sodium aluminate by 27Al and 29Si MAS NMR spectroscopy. Cem Concr Res 34:857–868. https://doi.org/10.1016/j.cemconres.2003.10.009

Engelhardt G, Michel D (1987) High-resolution solid-state NMR of Silicates and Zeolites. John Wiley and Son, Chichester

Bertron A, Duchesne J, Escadeillas G (2007) Degradation of cement pastes by organic acids. Mater Struct 40:341–354. https://doi.org/10.1617/s11527-006-9110-3

Lothenbach B, Kulik DA, Matschei T, Balonis M, Baquerizo L, Dilnesa B, Miron GD, Myers RJ (2019) Cemdata18: a chemical thermodynamic database for hydrated Portland cements and alkali-activated materials. Cem Concr Res 115:472–506. https://doi.org/10.1016/j.cemconres.2018.04.018

Pokrovski GS, Schott J, Farges F, Hazemann JL (2003) Iron (III)-silica interactions in aqueous solution: insights from X-ray absorption fine structure spectroscopy. Geochim Cosmochi Acta 67:3559–3573. https://doi.org/10.1016/S0016-7037(03)00160-1

Ninan CM, Radhakrishnan R, Ramaswamy KP, Sajeeb R, Thomas BS (2023) Performance evaluation of opc mortar exposed to organic acid environments. Mater Today Proc. https://doi.org/10.1016/j.matpr.2023.02.398

Scholze H (1991) Glass: nature, structure, and properties. Springer-Verlag, New York

Buchwald A, Hilbig H, Kaps C (2007) Alkali-activated metakaolin-slag blends—performance and structure in dependence of their composition. J Mater Sci 42:3024–3032. https://doi.org/10.1007/s10853-006-0525-6

Acknowledgements

The authors thank the German Research Foundation (DFG) (project no. 174059517) for financially supporting this research work.

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no competing interests to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hilbig, H., Gutberlet, T. & Beddoe, R.E. Acid attack on hydrated cement: effect of organic acids on the degradation process. Mater Struct 57, 83 (2024). https://doi.org/10.1617/s11527-024-02360-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-024-02360-8