Abstract

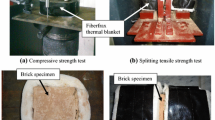

Earthen materials, one of the oldest known building materials, are also one of the most sustainable materials with promising properties to meet the environmental and economic challenges currently facing the construction industry. For its use in buildings and structures, this material has been studied in almost all of its thermo-hygro-mechanical aspects. However, the fire behavior of such materials is not well known and poorly documented. For this reason, the present study focuses on the fire behavior of compressed earth bricks compacted with variable compaction pressure in order to evaluate the risk of thermal instabilities during fire exposure. Different bricks were made from a mixture of earth and water with compaction pressures of 5, 15, 30 and 50 MPa. The bricks were set to an equilibration period at 75% RH until they were stable. According to previous research, this chosen relative humidity level corresponds to an unfavorable configuration with regard to the risk of thermal instabilities of compressed earth bricks. Each material configuration was subjected to two fire tests of 30 min. The results obtained showed that the risk of instability increased as the level of compaction increased. Further residual nitrogen permeability tests were performed to analyze the results obtained. It was found that the microstructure of the material upon its compaction plays an important role in the build-up vapor pore pressure during heating. This pore pressure was certainly responsible for the thermal instabilities observed.

Similar content being viewed by others

References

Hoffmann C, Alonso EE, Romero E (2007) Hydro-mechanical behaviour of bentonite pellet mixtures. Phys Chem Earth Parts ABC 32:832–849. https://doi.org/10.1016/j.pce.2006.04.037

Tang A-M, Cui Y-J, Le T-T (2008) A study on the thermal conductivity of compacted bentonites. Appl Clay Sci 41:181–189. https://doi.org/10.1016/j.clay.2007.11.001

Bui QB, Morel JC, Venkatarama Reddy BV, Ghayad W (2009) Durability of rammed earth walls exposed for 20 years to natural weathering. Build Environ 44:912–919. https://doi.org/10.1016/j.buildenv.2008.07.001

Bruno AW (2016), Hygro-mechanical characterisation of hypercompacted earth for building construction. PhD Thesis, Université de Pau et des Pays de l’Adour

Bruno AW, Gallipoli D, Perlot C, Mendes J (2016) Effect of very high compaction pressures on the physical and mechanical properties of earthen materials. E3S Web Conf 9:14004. https://doi.org/10.1051/e3sconf/20160914004

El Fgaier F, Lafhaj Z, Chapiseau C, Antczak E (2016) Effect of sorption capacity on thermo-mechanical properties of unfired clay bricks. J Build Eng 6:86–92. https://doi.org/10.1016/j.jobe.2016.02.011

Zhang L, Yang L, Jelle BP et al (2018) Hygrothermal properties of compressed earthen bricks. Constr Build Mater 162:576–583. https://doi.org/10.1016/j.conbuildmat.2017.11.163

Bruno AW, Gallipoli D, Perlot C, Kallel H (2020) Thermal performance of fired and unfired earth bricks walls. J Build Eng 28:101017. https://doi.org/10.1016/j.jobe.2019.101017

Ávila F, Puertas E, Gallego R (2021) Characterization of the mechanical and physical properties of unstabilized rammed earth: a review. Constr Build Mater 270:121435. https://doi.org/10.1016/j.conbuildmat.2020.121435

Hermathy TZ (1965) Effect of moisture on the fire endurance of building elements. Moisture in relation to fire tests. Mater ASTM Spec Tech Publ 385:74–95

Mindeguia J-C, Pimienta P, Noumowé A, Kanema M (2010) Temperature, pore pressure and mass variation of concrete subjected to high temperature—experimental and numerical discussion on spalling risk. Cem Concr Res 40:477–487

Brick Industry Association (2006) Manufacturing of brick. Technical notes on Brick Construction, Reston, Virginia

Murmu AL, Patel A (2018) Towards sustainable bricks production: an overview. Constr Build Mater 165:112–125. https://doi.org/10.1016/j.conbuildmat.2018.01.038

Zhang L (2013) Production of bricks from waste materials—a review. Constr Build Mater 47:643–655. https://doi.org/10.1016/j.conbuildmat.2013.05.043

Abdallah R (2022) The influence of thermal gradients on the fire behavior of raw earth and cement stabilized bricks at various water contents. Acad J Civil Eng. https://doi.org/10.26168/ajce.40.1.81

Abdallah RI, Perlot C, Carré H, et al (2022) Fire behavior of raw earth bricks: influence of water content and cement stabilization. Construction Technologies and Architecture. In: 4th International conference on bio-based building Materials, Trans Tech Publications Ltd., pp 792–800

Abdallah R, Carré H, Perlot C et al (2024) Study of the risk of instability in earthen bricks subjected to fire. Mater Struct. https://doi.org/10.1617/s11527-023-02284-9

International standard (1999) ISO 834-1. Fire resistance tests—elements of building construction. International Organization for Standardization

Byrne SM (1982) Fire resistance test on a loadbearing masonry wall of 25 cm thick adobe block work. Fire Technol. https://doi.org/10.1007/BF01983196

Buson M, Lopes N, Varum H et al (2013) Fire resistance of walls made of soil-cement and Kraftterra compressed earth blocks: soil–cement and Kraftterra CEBs. Fire Mater 37:547–562. https://doi.org/10.1002/fam.2148

Ferreira DM, Luso E, Cruz ML et al (2019) Fire behaviour of ecological soil–cement blocks with waste incorporation: experimental and numerical analysis. J Fire Sci 38:173–193. https://doi.org/10.1177/0734904119893921

Morel J-C, Pkla A, Walker P (2007) Compressive strength testing of compressed earth blocks. Constr Build Mater 21:303–309. https://doi.org/10.1016/j.conbuildmat.2005.08.021

McGregor F, Heath A, Shea A, Lawrence M (2014) The moisture buffering capacity of unfired clay masonry. Build Environ 82:599–607. https://doi.org/10.1016/j.buildenv.2014.09.027

Bruno AW, Gallipoli D, Perlot C, Mendes J (2019) Optimization of bricks production by earth hypercompaction prior to firing. J Clean Prod 214:475–482. https://doi.org/10.1016/j.jclepro.2018.12.302

Bui Q-B, Morel J-C, Hans S, Walker P (2014) Effect of moisture content on the mechanical characteristics of rammed earth. Constr Build Mater 54:163–169. https://doi.org/10.1016/j.conbuildmat.2013.12.067

Bruno AW, Perlot C, Mendes J, Gallipoli D (2018) A microstructural insight into the hygro-mechanical behaviour of a stabilised hypercompacted earth. Mater Struct Constr 51:17. https://doi.org/10.1617/s11527-018-1160-9

Akinshipe O, Kornelius G (2017) Chemical and thermodynamic processes in clay brick firing technologies and associated atmospheric emissions metrics—a review. J Pollut Eff Control. https://doi.org/10.4176/2375-4397.1000190

Serra MF, Conconi MS, Suarez G et al (2013) Firing transformations of an argentinean calcareous commercial clay. Ceramica 59:254–261. https://doi.org/10.1590/S0366-69132013000200010

Castellanos OMA, Ríos CAR, Ramos MAG, Plaza EVP (2012) A comparative study of mineralogical transformations in fired clays from the Laboyos valley, Upper Magdalena Basin (Colombia). Boletin Geol 34:43–55

Kollek JJ (1989) The determination of the permeability of concrete to oxygen by the Cembureau method—a recommendation. Mater Struct 22:6. https://doi.org/10.1007/BF02472192

Klinkenberg LJ (1941) The permeability of porous media to liquids and gases. In: American Petrolium Institute, Drilling and Production Practice. American Petrolium Institute, Drilling and Production Practice, pp 200–213

Dal Pont S (2004), Lien entre la perméabilité et l’endommagement dans les bétons à haute température. PhD Thesis, Ecole Nationale Des Ponts Et Chaussees

Mindeguia J-C, Carré H, Pimienta P, La Borderie C (2015) Experimental discussion on the mechanisms behind the fire spalling of concrete: mechanisms behind the fire spalling of concrete. Fire Mater 39:619–635. https://doi.org/10.1002/fam.2254

Kodur V (2014) Properties of concrete at elevated temperatures. ISRN Civ Eng 2014:1–15. https://doi.org/10.1155/2014/468510

Kodur V, Banerji S, Solhmirzaei R (2020) Effect of temperature on thermal properties of ultrahigh-performance concrete. J Mater Civil Eng. https://doi.org/10.1061/(ASCE)MT.1943-5533.0003286

Beckett C, Kazamias K, Law A (2019) Investigation into the high temperature behaviour of unstabilised rammed earth. In: Fifth International Conference on Sustainable Construction Materials and Technologies. London, p 12

Mindeguia J-C, Pimienta P, Carré H, La Borderie C (2013) Experimental analysis of concrete spalling due to fire exposure. Eur J Environ Civ Eng 17:453–466. https://doi.org/10.1080/19648189.2013.786245

Noumowe AN, Siddique R, Debicki G (2009) Permeability of high-performance concrete subjected to elevated temperature (600 °C). Constr Build Mater 23:1855–1861

Amran M, Murali G, Makul N et al (2023) Fire-induced spalling of ultra-high performance concrete: a systematic critical review. Constr Build Mater 373:130869. https://doi.org/10.1016/j.conbuildmat.2023.130869

Ma Q, Guo R, Zhao Z et al (2015) Mechanical properties of concrete at high temperature—a review. Constr Build Mater 93:371–383. https://doi.org/10.1016/j.conbuildmat.2015.05.131

Liu J-C, Tan KH, Yao Y (2018) A new perspective on nature of fire-induced spalling in concrete. Constr Build Mater 184:581–590. https://doi.org/10.1016/j.conbuildmat.2018.06.204

Zeiml M, Leithner D, Lackner R, Mang HA (2006) How do polypropylene fibers improve the spalling behavior of in-situ concrete? Cem Concr Res 36:929–942. https://doi.org/10.1016/j.cemconres.2005.12.018

McNamee R (2019) Fire spalling theories-realistic and more exotic ones. In: Proceedings of the 6th International workshop on concrete spalling. Sheffield, UK

Fernandes B, Carré H, Mindeguia J-C et al (2022) Spalling behaviour of concrete made with recycled concrete aggregates. Constr Build Mater 344:128124. https://doi.org/10.1016/j.conbuildmat.2022.128124

Khoury GA, Anderberg Y (2000) Concrete spalling review. Fire Saf Des 60:5–12

Khoury GA (2001) Effect of fire on concrete and concrete structures. Prog Struct Eng Mater 2:429–447

McNamee R, Boström L (2009) The influence of pressure in the pore system on fire spalling of concrete. Fire Technol 46:217–230. https://doi.org/10.1007/s10694-009-0093-9

McNamee R (2013) Fire spalling of concrete—a historical overview. MATEC Web Conf 6:01001. https://doi.org/10.1051/matecconf/20130601001

Balaji NC, Praseeda KI, Monto M, Reddy BVV (2015) Influence of varying mix proportions on thermal performance of soil-cement blocks. In: Proceedings of the 2nd IBPSA Italy conference, building simulation application. 8,Bolzano, Italy

Bei S, Zhixiang L (2016) Investigation on spalling resistance of ultra-high-strength concrete under rapid heating and rapid cooling. Case Stud Constr Mater 4:146–153. https://doi.org/10.1016/j.cscm.2016.04.001

Zhang D, Dasari A, Tan KH (2018) On the mechanism of prevention of explosive spalling in ultra-high performance concrete with polymer fibers. Cem Concr Res 113:169–177. https://doi.org/10.1016/j.cemconres.2018.08.012

Hager I, Mróz K (2019) Role of polypropylene fibres in concrete spalling risk mitigation in fire and test methods of fibres effectiveness evaluation. Materials 12:20

Sultangaliyeva F, Fernandes B, Carré H, et al (2019) Experimental contribution to the optimization of the choice of polypropylene fibers in concrete for its thermal stability. In: 6th International workshop on concrete spalling due to fire exposure

Igra Pohowe S, Abdallah R, Pliya P, Beaucour A-L (2023) Influence of sawdust and flax shives on the high temperature mechanical behavior of earthen materials. Mater Today Proc. https://doi.org/10.1016/j.matpr.2023.06.240

Siyapze F, Pliya P, Abdallah R, Beaucour A-L (2023) Influence of sawdust and soil type on the high temperature behavior of raw earth bricks. Mater Today Proc. https://doi.org/10.1016/j.matpr.2023.07.093

Acknowledgements

This study has received funding from the Chair ContstrucTerr (UPPA).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Abdallah, R., Carré, H. & McGregor, F. Effect of compaction pressure on the risk of thermal instability of compressed earth bricks. Mater Struct 57, 84 (2024). https://doi.org/10.1617/s11527-024-02348-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-024-02348-4