Abstract

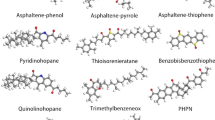

Cold-mixed epoxy asphalt (CEA) is a superior pavement material that can be constructed and cured at room temperature, attracting increasing attention. However, the lack of research on CEA molecular model selection, structure, and energy evolution during curing has limited the accuracy of CEA performance research. To address this, three kinds of CEA molecular models were established: the Mixing model, the epoxy resin (ER)-asphalt interface (RA) model, and the ER-asphalt-ER interface (RAR) model. Their accuracy in describing the basic properties, structure, energy evolution, and mechanical properties of CEA was investigated and compared with experimental results. The RAR model was found to be the closest to the real structure. The curing process did not change the phase structure of CEA significantly, which maintained a "sea-island" structure with new hydrogen bonds forming between the ER and asphalt molecules. The crosslinking of ER consumed polar epoxy groups in CEA, resulting in a decrease of valence bond energy by up to 29.1% and an increase of van der Waals energy by up to 104.3% for the RAR model. The curing network also restricted the molecular chain movement and fixed the intermolecular distance and orientation. It was suggested that uniaxial tension simulation should be performed at 3 × 10–5/fs under the NPT ensemble when not studying yield behavior. The main fracture mechanisms of CEA were crack deflection, pinning, debonding, and asphalt particle pull-out. Many short-range rigid segments in CEA also explained its high strength.

Similar content being viewed by others

References

Xiang Q, Xiao FP (2020) Applications of epoxy materials in pavement engineering. Constr Build Mater 235:117529. https://doi.org/10.1016/j.conbuildmat.2019.117529

Jamshidi A, White G, Kurumisawa K (2022) Functional and field performance of epoxy asphalt technology: state-of-the-art. Road Mater Pavement 24(4):881–918. https://doi.org/10.1080/14680629.2022.2060128

Xie HF, Li C, Wang Q (2023) Thermosetting polymer modified asphalts: current status and challenges. Polym Rev. https://doi.org/10.1080/15583724.2023.2286706

Xie HF, Li CX, Wang QJ (2022) A critical review on performance and phase separation of thermosetting epoxy asphalt binders and bond coats. Constr Build Mater 326:126792. https://doi.org/10.1016/j.conbuildmat.2022.126792

Wang JY, Yu X, Ding GY, Si JJ, Zhang MZ, Jiang ZQ (2023) Dynamic mechanical behavior of cold-mixed epoxy asphalt under high strain rates. J Mater Civ Eng 35(5):04023068. https://doi.org/10.1061/(ASCE)MT.1943-5533.0004724

Apostolidis P, Elwardany M, Andriescu A, Mensching DJ, Youtcheff J (2023) Study of phase behavior of epoxy asphalt binders using differential scanning calorimetry. Constr Build Mater 369:130566. https://doi.org/10.1016/j.conbuildmat.2023.130566

Ngezahayo E, Eskandari Torbaghan M, Metje N, Burrow M, Ghataora GS, Desalegn Y (2023) Investigating the effectiveness of fourier transform infrared spectroscopy (FTIR) as an antifraud approach for modified epoxy asphalt mixes in developing countries. Sustainability 15(23):16332. https://doi.org/10.3390/su152316332

Bahmani H, Sanij HK, Peiravian F (2021) Estimating moisture resistance of asphalt mixture containing epoxy resin using surface free energy method and modified lottman test. Int J Pavement Eng 23(10):3492–3504. https://doi.org/10.1080/10298436.2021.1904236

Min ZH, Wang QC, Xie YX, Xie JQ, Zhang B (2021) Influence of polyethylene glycol (PEG) chain on the performance of epoxy asphalt binder and mixture. Constr Build Mater 272:121614. https://doi.org/10.1016/j.conbuildmat.2020.121614

Liu Y, Zhang J, Jiang YJ, Li CX, Xi ZH, Cai J et al (2018) Investigation of secondary phase separation and mechanical properties of epoxy SBS-modified asphalts. Constr Build Mater 165:163–172. https://doi.org/10.1016/j.conbuildmat.2018.01.032

Jiang YJ, Liu Y, Gong J, Li CX, Xi ZH, Cai J et al (2018) Microstructures, thermal and mechanical properties of epoxy asphalt binder modified by SBS containing various styrene-butadiene structures. Mater Struct 51(4):1–13. https://doi.org/10.1617/s11527-018-1217-9

Jiang YJ, Zhao RK, Xi ZH, Cai J, Yuan ZR, Zhang JS et al (2021) Improving toughness of epoxy asphalt binder with reactive epoxidized SBS. Mater Struct 54(4):1–17. https://doi.org/10.1617/s11527-021-01744-4

Su WF, Han XC, Gong J, Xi ZH, Zhang JS, Wang QJ et al (2020) Toughening epoxy asphalt binder using core-shell rubber nanoparticles. Constr Build Mater 258:119716. https://doi.org/10.1016/j.conbuildmat.2020.119716

Liu Y, Zhang J, Chen R, Cai J, Xi ZH, Xie HF (2017) Ethylene vinyl acetate copolymer modified epoxy asphalt binders: phase separation evolution and mechanical properties. Constr Build Mater 137:55–65. https://doi.org/10.1016/j.conbuildmat.2017.01.081

Hu J, Qian Z, Xue Y, Yang Y (2016) Investigation on fracture performance of lightweight epoxy asphalt concrete based on microstructure characteristics. J Mater Civ Eng 28(9):1594. https://doi.org/10.1061/(asce)mt.1943-5533.0001594

Sun J, Zhang Z, Wang L, Liu H, Ban X, Ye J (2022) Investigation on the epoxy/polyurethane modified asphalt binder cured with bio-based curing agent: properties and optimization. Constr Build Mater 320:126221. https://doi.org/10.1016/j.conbuildmat.2021.126221

Kumar S, Krishnan S, Samal SK, Mohanty S, Nayak SK (2018) Toughening of petroleum based (DGEBA) epoxy resins with various renewable resources based flexible chains for high performance applications: a review. Ind Eng Chem Res 57(8):2711–2726. https://doi.org/10.1021/acs.iecr.7b04495

Kang Y, Chen Z, Jiao Z, Huang W (2010) Rubber-like thermosetting epoxy asphalt composites exhibiting atypical yielding behaviors. J Appl Polym Sci 116(3):1678–1685. https://doi.org/10.1002/app.31563

Si JJ, Jia ZX, Wang JY, Yu X, Li Y, Dong FQ et al (2018) Comparative analysis of cold-mixed epoxy and epoxy sbs-modified asphalts: curing rheology, thermal, and mechanical properties. Constr Build Mater 176:165–171. https://doi.org/10.1016/j.conbuildmat.2018.05.035

Qu X, Wang DW, Wang LB, Huang YC, Hou Y, Oeser M (2018) The state-of-the-art review on molecular dynamics simulation of asphalt binder. Adv Civil Eng 2018:1–14. https://doi.org/10.1155/2018/4546191

Ren SS, Liu XY, Lin P, Gao YM, Erkens S (2022) Molecular dynamics simulation on bulk bitumen systems and its potential connections to macroscale performance: review and discussion. Fuel 328:125382. https://doi.org/10.1016/j.fuel.2022.125382

Li M, Min Z, Wang Q, Huang W, Shi Z (2022) Effect of epoxy resin content and conversion rate on the compatibility and component distribution of epoxy asphalt: a MD simulation study. Constr Build Mater 319:126050. https://doi.org/10.1016/j.conbuildmat.2021.126050

Liu Q, Ding GY, Zhang ZY, Fu CL, Oeser M (2021) Investigation on bitumen-epoxy interface in cold mixed epoxy bitumen using experimental observation and molecular dynamics simulation. Constr Build Mater 303:124490. https://doi.org/10.1016/j.conbuildmat.2021.124490

Yu X, Wang JY, Si JJ, Mei J, Ding GY, Li JB (2020) Research on compatibility mechanism of biobased cold-mixed epoxy asphalt binder. Constr Build Mater 250:118868. https://doi.org/10.1016/j.conbuildmat.2020.118868

Ding GY, Yu X, Si JJ, Mei J, Wang JY, Chen B (2021) Influence of epoxy soybean oil modified nano-silica on the compatibility of cold-mixed epoxy asphalt. Mater Struct 54(1):1–8. https://doi.org/10.1617/s11527-020-01611-8

Zhang L (2007) Physical and mechanical properties of model asphalt systems calculated using molecular simulation. University of Rhode Island, Kingston

Hansen JS, Lemarchand CA, Nielsen E, Dyre JC, Schroder T (2013) Four-component united-atom model of bitumen. J Chem Phys 138(9):094508. https://doi.org/10.1063/1.4792045

Zhang L, Greenfield ML (2007) Analyzing properties of model asphalts using molecular simulation. Energy Fuels 21(3):1712–1716. https://doi.org/10.1021/ef060658j

Li DD, Greenfield ML (2014) Chemical compositions of improved model asphalt systems for molecular simulations. Fuel 115:347–356. https://doi.org/10.1016/j.fuel.2013.07.012

Xu JY, Ma B, Mao WJ, Si W, Wang X (2023) Review of interfacial adhesion between asphalt and aggregate based on molecular dynamics. Constr Build Mater 362:129642. https://doi.org/10.1016/j.conbuildmat.2022.129642

Li F, Yang YY, Wang LB (2021) The interfacial interaction between asphalt binder and mineral filler: a comprehensive review on mechanisms, evaluation methods and influence factors. Int J Pavement Eng. https://doi.org/10.1080/10298436.2021.1942468

Jain S, Chandrappa AK (2023) Critical review on waste cooking oil rejuvenation in asphalt mixture with high recycled asphalt. Environ Sci Pollut Res 30(32):77981–78003. https://doi.org/10.1007/s11356-023-28098-4

Zadshir M, Hosseinnezhad S, Fini EH (2019) Deagglomeration of oxidized asphaltenes as a measure of true rejuvenation for severely aged asphalt binder. Constr Build Mater 209:416–424. https://doi.org/10.1016/j.conbuildmat.2019.03.090

Samieadel A, Høgsaa B, Fini EH (2018) Examining the implications of wax-based additives on the sustainability of construction practices: multiscale characterization of wax-doped aged asphalt binder. ACS Sustainable Chem Eng 7(3):2943–2954. https://doi.org/10.1021/acssuschemeng.8b03842

Pahlavan F, Samieadel A, Deng S, Fini E (2019) Exploiting synergistic effects of intermolecular interactions to synthesize hybrid rejuvenators to revitalize aged asphalt. ACS Sustain Chem Eng 7(18):15514–15525. https://doi.org/10.1021/acssuschemeng.9b03263

Shariati S, Rajib AI, Crocker MS, Ackerman-Biegasiewicz LKG, Martis V, Fini EH (2022) Bio-grafted silica to make an asphalt road a sink for reactive environmental pollutants. Environ Pollut 313:120142. https://doi.org/10.1016/j.envpol.2022.120142

Quezada GR, Solar C, Saavedra JH, Petit K, Martin-Martínez FJ, Arteaga-Pérez LE et al (2024) Operando FTIR-ATR with molecular dynamic simulations to understand the diffusion mechanism of waste tire-derived pyrolytic oil for asphalt self-healing. Fuel 357:129834. https://doi.org/10.1016/j.fuel.2023.129834

Wang JY, Yu X, Ding GY, Si JJ, Xing M, Xie R (2022) Strength and toughness attenuation mechanism of biobased cold-mixed epoxy asphalt under freeze–thaw cycles. Int J Pavement Eng. https://doi.org/10.1080/10298436.2022.2075553

Wang JY, Yu X, Ding GY, Si JJ, Ruan W, Zou XY (2021) Influence of asphalt solvents on the rheological and mechanical properties of cold-mixed epoxy asphalt. Constr Build Mater 310:125245. https://doi.org/10.1016/j.conbuildmat.2021.125245

Sun W, Wang H (2020) Moisture effect on nanostructure and adhesion energy of asphalt on aggregate surface: a molecular dynamics study. Appl Surf Sci 510:145435. https://doi.org/10.1016/j.apsusc.2020.145435

Xu GJ, Wang H (2017) Molecular dynamics study of oxidative aging effect on asphalt binder properties. Fuel 188:1–10. https://doi.org/10.1016/j.fuel.2016.10.021

Wang JY, Si JJ, Yu X, Jiang ZQ, Zhang MZ, Ding GY et al (2023) Enhancing the compatibility of cold-mixed epoxy asphalt binder via graphene oxide grafted plant oil-based materials. J Clean Prod 418:138209. https://doi.org/10.1016/j.jclepro.2023.138209

Tang J, Wang H, Liang M (2022) Molecular simulation and experimental analysis of interaction and compatibility between asphalt binder and styrene-butadiene-styrene. Constr Build Mater 342:128028. https://doi.org/10.1016/j.conbuildmat.2022.128028

Li C, Strachan A (2011) Molecular dynamics predictions of thermal and mechanical properties of thermoset polymer EPON862/DETDA. Polymer 52(13):2920–2928. https://doi.org/10.1016/j.polymer.2011.04.041

Chen R, Gong J, Jiang YJ, Wang QJ, Xi ZH, Xie HF (2018) Halogen-free flame retarded cold-mix epoxy asphalt binders: rheological, thermal and mechanical characterization. Constr Build Mater 186:863–870. https://doi.org/10.1016/j.conbuildmat.2018.08.018

Zhang J, Su WF, Liu Y, Gong J, Xi ZH, Zhang JS et al (2021) Laboratory investigation on the microstructure and performance of SBS modified epoxy asphalt binder. Constr Build Mater 270:121378. https://doi.org/10.1016/j.conbuildmat.2020.121378

Xu PJ, Du X, Cong P, Zhou Z (2020) Properties of paving epoxy asphalt with epoxy-terminated hyperbranched polyester. Road Mater Pavement 23(1):234–246. https://doi.org/10.1080/14680629.2020.1826342

Zeng QW, Gao PW, Xu YF, Dong GQ, Chen MM, Zhao JW et al (2021) Laboratory research and evaluation on design and application performance of high-performance cold-mix resin. Materials 14(17):4828. https://doi.org/10.3390/ma14174828

Li X, Kang HL, Shen JX, Zhang LQ, Nishi T, Ito K (2015) Miscibility, intramolecular specific interactions and mechanical properties of a DGEBA based epoxy resin toughened with a sliding graft copolymer. Chin J Polym Sci 33(3):433–443. https://doi.org/10.1007/s10118-015-1596-0

Meure S, Wu DY, Furman SA (2010) FTIR study of bonding between a thermoplastic healing agent and a mendable epoxy resin. Vib Spectrosc 52(1):10–15. https://doi.org/10.1016/j.vibspec.2009.09.005

Polacco G, Filippi S, Merusi F, Stastna G (2015) A review of the fundamentals of polymer-modified asphalts: asphalt/polymer interactions and principles of compatibility. Adv Colloid Interface Sci 224:72–112. https://doi.org/10.1016/j.cis.2015.07.010

Chowdhury SC, Elder RM, Sirk TW, Gillespie JW (2020) Epoxy resin thermo-mechanics and failure modes: effects of cure and cross-linker length. Compos Part B-Eng. 186:107814. https://doi.org/10.1016/j.compositesb.2020.107814

Yang S, Gao F, Qu J (2013) A molecular dynamics study of tensile strength between a highly-crosslinked epoxy molding compound and a copper substrate. Polymer 54(18):5064–5074. https://doi.org/10.1016/j.polymer.2013.07.019

Ramezanzadeh M, Bahlakeh G, Ramezanzadeh B (2019) Development of a nanostructured Ce(III)-Pr(III) film for excellently corrosion resistance improvement of epoxy/polyamide coating on carbon steel. J Alloys Compd 792:375–388. https://doi.org/10.1016/j.jallcom.2019.04.051

Pires de Oliveira I, Caires ARL (2019) Molecular arrangement in diesel/biodiesel blends: a molecular dynamics simulation analysis. Renewable Energy 140:203–211. https://doi.org/10.1016/j.renene.2019.03.061

Nie FH, Jian W, Lau D (2021) An atomistic study on the thermomechanical properties of graphene and functionalized graphene sheets modified asphalt. Carbon 182:615–627. https://doi.org/10.1016/j.carbon.2021.06.055

Acknowledgements

This work was supported by the National Key Research and Development Program of China [Grant No. 2021YFB2601200] and the National Natural Science Foundation of China [Grant No. 52078191] and the Natural Science Foundation of Jiangsu Province [Grant No. BK20231463].

Author information

Authors and Affiliations

Contributions

Junyan Wang: Conceptualization, formal analysis, methodology, data curation, and writing—original draft, and writing—review and editing. Xin Yu: Conceptualization, investigation, and writing—review and editing, funding acquisition, project administration, supervision. Jingjing Si: Conceptualization, funding acquisition, investigation, and writing—review and editing. Shuang Zhao and Wuyang Wei: Data curation, formal analysis and methodology. Gongying Ding: Data curation and validation.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, J., Yu, X., Si, J. et al. Comparative analysis of cold-mixed epoxy asphalt models for molecular dynamics simulation: structural, curing and mechanical properties. Mater Struct 57, 61 (2024). https://doi.org/10.1617/s11527-024-02320-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-024-02320-2