Abstract

In pavement engineering, cold recycled material (CRM) mixtures allow implementing circular economy concepts by maximizing the reuse of reclaimed asphalt without heating. Along with bitumen emulsion and foamed bitumen, Portland cement is often added to CRM mixtures to improve the field performance. However, the role of cement on the fatigue failure is not sufficiently investigated. The objective of this research is to provide new insights into the fatigue failure of CRM mixtures produced with bitumen emulsion and cement. To this aim, two CRM mixtures prepared with different dosages of cement (1 and 2%) were subjected to uniaxial cyclic tension fatigue tests. Empirical and energy-based failure criteria, originally developed for asphalt concrete mixtures, were used to define the fatigue failure. The results showed that the fatigue failure mechanism of CRM mixtures was of a composite type, affected by both cementitious and bituminous bonds. A new criterion was proposed to identify the failure of the cementitious bonds.

Similar content being viewed by others

References

Wiesmeth H (2020) Implementing the circular economy for sustainable development. Elsevier. Amsterdam. ISBN 9780128217986. https://doi.org/10.1016/C2019-0-04150-7.

Cross S, Chesner W, Justus H, Kearney E (2011) Life-cycle environmental analysis for evaluation of pavement rehabilitation options. Transp Res Rec 2227:43–52

Giani MI, Dotelli G, Brandini N, Zampori L (2015) Comparative life cycle assessment of asphalt pavements using reclaimed asphalt, warm mix technology and cold in-place recycling. Resour Conserv Recycl 104:224–238

Thenoux G, González A, Dowling R (2007) Energy consumption comparison for different asphalt pavements rehabilitation techniques used in Chile. Resour Conserv Recycl 49(4):325–339

Thives LP, Ghisi E (2017) Asphalt mixtures emission and energy consumption: a review. Renew Sustain Energy Rev 72:473–484

Dołżycki B, Jaskuła P (2019) Review and evaluation of cold recycling with bitumen emulsion and cement for rehabilitation of old pavements. J Traffic Transportation Eng (English Edition) 6(4):311–323

Dolzycki B, Jaczewski M, Szydlowski C (2017) The long-term properties of mineral-cement-emulsion mixtures. Constr Build Mater 156:799–808

Godenzoni C, Graziani A, Bocci E, Bocci M (2018) The evolution of the mechanical behaviour of cold recycled mixtures stabilised with cement and bitumen: field and laboratory study. Road Mater Pavement Des 19(4):856–877

Guatimosim FV, Vasconcelos KL, Bernucci LLB, Jenkins KJ (2018) Laboratory and field evaluation of cold recycling mixture with foamed asphalt. Road Mater Pavement Des 19(2):385–399

Kuchiishi AK, Santos Antão CCD, Vasconcelos K, Bernucci LLB (2019) Influence of viscoelastic properties of cold recycled asphalt mixtures on pavement response by means of temperature instrumentation. Road Mater Pavement Des 20(sup2):S710–S724

Fedrigo W, Núñez WP, Visser AT (2020) A review of full-depth reclamation of pavements with Portland cement: Brazil and abroad. Constr Build Mater 262:120540

Fedrigo W, Núñez WP, Schreinert GG, Kleinert TR, Matuella MF, Castañeda López MA, Ceratti JAP (2021) Flexural strength, stiffness and fatigue of cement-treated mixtures of reclaimed asphalt pavement and lateritic soil. Road Mater Pavement Des 22(5):1004–1022

SABITA (2020) Technical guideline: Bitumen stabilised materials. A Guideline for the Design and Construction of Bitumen Emulsion and Foamed Bitumen Stabilised Materials.

Orosa P, Pérez I, Pasandín AR (2022) Evaluation of the shear and permanent deformation properties of cold in-place recycled mixtures with bitumen emulsion using triaxial tests. Constr Build Mater 328:127054

Bocci M, Grilli A, Cardone F, Graziani A (2011) A study on the mechanical behaviour of cement-bitumen treated materials. Constr Build Mater 25(2):773–778

Buczyński P, Iwański M (2017) Fatigue life comparison of recycled cold mixes with foamed bitumen and with bitumen emulsion. Proc Eng 172:135–142

Dolzycki B, Szydlowski C, Jaczewski M (2020) The influence of combination of binding agents on fatigue properties of deep cold in-place recycled mixtures in Indirect Tensile Fatigue Test (ITFT). Constr Build Mater 239:117825

Kavussi A, Modarres A (2010) Laboratory fatigue models for recycled mixes with bitumen emulsion and cement. Constr Build Mater 24(10):1920–1927

Leandri P, Losa M, Di Natale A (2015) Field validation of recycled cold mixes viscoelastic properties. Constr Build Mater 75:275–282

Stimilli A, Ferrotti G, Graziani A, Canestrari F (2013) Performance evaluation of a cold-recycled mixture containing high percentage of reclaimed asphalt. Road Mater Pavement Des 14(SUPPL.1):149–161.

Chelelgo K, Gariy ZCA, Shitote SM (2019) Modeling of fatigue-strength development in cold-emulsion asphalt mixtures using maturity method. Appl Sci 9(13):2694

Ebels L-J (2008) Characterisation of material properties and behaviour of cold bituminous mixtures for road pavements. PhD Dissertation, Stellenbosch University, South Africa.

Huang W, Cao M, Xiao L, Li J, Zhu M (2023) Experimental study on the fatigue performance of emulsified asphalt cold recycled mixtures. Constr Build Mater 369:130607

Di Benedetto H, Perraton D, Lamothe S, Boussabnia MM (2023) Rational relationship between the fatigue curves of asphalt mixes obtained from tension/compression and 4-point bending tests. Road Mater Pavement Des 24(sup1):192–208

Di Benedetto H, Partl MN, Francken L, La Roche De, Saint André C (2001) Stiffness testing for bituminous mixtures. Mater Struct 34(2):66–70

Nemati R, Dave EV, Sias JE, Thibodeau ES, Worsman RK (2019) Evaluation of laboratory performance and structural contribution of cold recycled versus hot mixed intermediate and base course asphalt layers in new Hampshire. Transp Res Rec 2673(6):467–476

Tavassoti P, Solaimanian M, Chen X (2022) Characterization of fatigue performance of cold mix recycled asphalt mixtures through uniaxial tension-compression testing. Constr Build Mater 329:127155

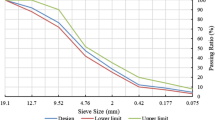

EN 13043 (2002) Aggregates for bituminous mixtures and surface treatments for roads, airfields and other trafficked areas.

EN 13808 (2013) Bitumen and bituminous binders – Framework for specifying cationic bituminous emulsions.

EN 197-1 (2011) Cements—Part 1: Composition, specifications and conformity criteria for common cements.

Winter M, Mollenhauer K, Graziani A, Mignini C, Giancontieri G, Lo Presti D, Bjurström H, Kalman B, Hornych P, Gaudefroy V (2020) Design of flexible pavements with cold recycled asphalt bases: Comparison of five national approaches. In: Proceedings of the 8th Transport Research Arena TRA 2020.

Mignini C, Cardone F, Graziani A (2022) Complex modulus of cement-bitumen treated materials produced with different reclaimed asphalt gradations. Mater Struct 55(7):169

Spadoni S, Ingrassia LP, Jaskuła P, Canestrari F (2023) Advanced fatigue and rutting characterisation of Polish asphalt mixtures based on the VECD model and viscoplastic shift model. Road Mater Pavement Des 24(S1):145–159

Graziani A, Raschia S, Mignini C, Carter A, Perraton D (2020) Use of fine aggregate matrix to analyze the rheological behavior of cold recycled materials. Mater Struct 53(4):72

EN 12697-31 (2019) Bituminous mixtures—test methods—Part 31: Specimen preparation by gyratory compactor.

Grilli A, Graziani A, Bocci E, Bocci M (2016) Volumetric properties and influence of water content on the compactability of cold recycled mixtures. Mater Struct 49:4349–4362

Cardone F, Grilli A, Bocci M, Graziani A (2014) Curing and temperature sensitivity of cement–bitumen treated materials. Int J Pavement Eng 16(10):868–880

EN 12697-6, 2020. Bituminous mixtures—Test methods—Part 6: Determination of bulk density of bituminous specimens.

EN 12697-8 (2018) Bituminous mixtures—Test methods—Part 8: Determination of void characteristics of bituminous specimens.

AASHTO PP 99 (2019) Standard Practice for Preparation of Small Cylindrical Performance Test Specimens Using the Superpave Gyratory Compactor (SGC) or Field Cores.

AASHTO T 400 (2023) Standard method of test for determining the damage characteristic curve and failure criterion using the Asphalt Mixture Performance Tester (AMPT) cyclic fatigue test.

Underwood BS, Kim YR, Guddati MN (2010) Improved calculation method of damage parameter in viscoelastic continuum damage model. Int J Pavement Eng 11(6):459–476

Jaczewski M, Szydlowski C, Dolzycki B (2022) Preliminary study of linear viscoelasticity limits of cold recycled mixtures determined in Simple Performance Tester (SPT). Constr Build Mater 357:129432

Jaczewski M, Szydłowski C, Dołżycki B (2023) Stiffness of cold-recycled mixtures under variable deformation conditions in the IT-CY test. Case Stud Construct Mater 18:e02066

Bhasin A, Castelo Branco VF, Masad E, Little DN (2009) Quantitative comparison of energy methods to characterize fatigue in asphalt materials. J Mater Civ Eng 21(2):83–92

Gajewski M, Bańkowski W, Pronk AC (2020) Evaluation of fatigue life of high modulus asphalt concrete with use of three different definitions. Int J Pavement Eng 21(14):1717–1728

Shen S, Lu X (2011) Energy based laboratory fatigue failure criteria asphalt materials. J Test Eval 39(3):103088

Sudarsanan N, Kim YR (2022) A critical review of the fatigue life prediction of asphalt mixtures and pavements. J Traffic Transportation Eng (English Edition) 9(5):808–835

AASHTO T 321 (2017) Standard method of test for determining the fatigue life of compacted asphalt mixtures subjected to repeated flexural bending.

EN 12697-24 (2018) Bituminous mixtures—Test methods—Part 24: Resistance to fatigue.

Reese R (1997) Properties of aged asphalt binder related to asphalt concrete fatigue life. J Assoc Asphalt Paving Technol 66:604–632

Pronk AC, Hopman PC (1991) Energy dissipation: the leading factor of fatigue. Highway Research: Sharing the Benefits. Thomas Telford Publishing, London, pp 255–267

Van Dijk W (1975) Practical fatigue characterization of bituminous mixes. Proc Assoc Asphalt Paving Technol (AAPT) (AAPT) 44:38–74

Van Dijk W, Visser W (1977) The energy approach to fatigue for pavement design. Proc Assoc Asphalt Paving Technol (AAPT) 46:1–40

Monismith CL, Deacon JA (1969) Fatigue of asphalt paving mixtures. Transp Eng J ASCE 95(2):317–346

Di Benedetto H, De La Roche C, Baaj H, Pronk A, Lundström R (2004) Fatigue of bituminous mixtures. Mater Struct 37(267):202–216

Lee KC (2020) Improvement in dynamic modulus and cyclic fatigue testing of asphalt mixture. PhD Thesis, North Carolina State University.

Virgili A, Canestrari F, Grilli A, Santagata FA (2009) Repeated load test on bituminous systems reinforced by geosynthetics. Geotext Geomembr 27(3):187–195

Tapsoba N, Sauzéat C, Di Benedetto H (2013) Analysis of fatigue test for bituminous mixtures. J Mater Civ Eng 25(6):701–710

Funding

No funding was received for conducting this study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

The authors have no competing interests to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Graziani, A., Spadoni, S., Ingrassia, L.P. et al. Composite fatigue failure of cold recycled material mixtures: new insights into the role of bitumen and cement. Mater Struct 57, 10 (2024). https://doi.org/10.1617/s11527-023-02285-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-023-02285-8