Abstract

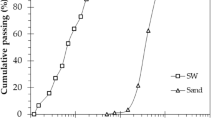

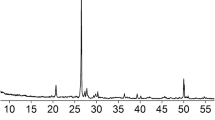

This paper discusses the physical, mechanical, hygric, and photoactive behaviour of photocatalytic coloured rendering mortars. 4% yellow, 4% brown, and 6% black iron oxide pigments were studied with 0%, 5%, and 10% titanium dioxide (TiO2) contents concerning white cement weight, resulting in twelve mortar types, including references. Mainly the addition of TiO2 and yellow pigment affected and reduced the mixtures’ flowability. Besides, mortars’ production was challenging due to the standard material quantities and execution methods. The presence of fine materials, the aggregates’ granulometry and the addition of superplasticiser resulted in mortars with high cohesion, entraining air; so, decreases in bulk density and, in some cases, mechanical strength were verified, especially for increasing contents of TiO2. Water absorption by capillarity decreased with the photocatalyst addition, while a minor impact was verified on the water vapour diffusion resistance factors. The pigments did not significantly influence the hygric behaviour. The photocatalytic efficacy of TiO2 was confirmed by RhB degradation tests. Mortars without pigments led to the highest colour differences (ΔE) throughout irradiation exposure irrespectively of the presence of 5% or 10% photocatalyst; yellow and brown mortars had increasing RhB degradation with increasing TiO2 contents and lower ΔE results than the specimens with no pigment. Black mortars were not efficiently evaluated through RhB degradation. The study’s novelty addresses the gap in understanding the combined effects of TiO2 with iron oxide pigments, and the investigation is primarily relevant to the practical application of photocatalytic coloured mortars in building facades, seeking aesthetic, economic and environmental benefits.

Similar content being viewed by others

References

Damas AL, do Rosário-Veiga M, Faria P, Silva AS (2018) Characterisation of old azulejos setting mortars: a contribution to the conservation of this type of coatings. Constr Build Mater 171:128–139. https://doi.org/10.1016/j.conbuildmat.2018.03.103

López A, Guzmán GA, Di Sarli AR (2016) Color stability in mortars and concretes. Part 1: study on architectural mortars. Constr Build Mater 120:617–622. https://doi.org/10.1016/j.conbuildmat.2016.05.133

Diamanti MV, Paolini R, Rossini M et al (2015) Long term self-cleaning and photocatalytic performance of anatase added mortars exposed to the urban environment. Constr Build Mater 96:270–278. https://doi.org/10.1016/j.conbuildmat.2015.08.028

Fernandes CN, Ferreira RLS, Bernardo RDS et al (2020) Using TiO2 nanoparticles as a SO2 catalyst in cement mortars. Constr Build Mater 257:119542. https://doi.org/10.1016/j.conbuildmat.2020.119542

Monteiro H, Moura B, Soares N (2022) Advancements in nano-enabled cement and concrete: innovative properties and environmental implications. J Build Eng 56:104736. https://doi.org/10.1016/j.jobe.2022.104736

De Richter R, Caillol S (2011) Fighting global warming: the potential of photocatalysis against CO2, CH4, N2O, CFCs, tropospheric O3, BC and other major contributors to climate change. J Photochem Photobiol C Photochem Rev 12:1–19. https://doi.org/10.1016/j.jphotochemrev.2011.05.002

Folli A, Pade C, Hansen TB et al (2012) TiO2 photocatalysis in cementitious systems: insights into self-cleaning and depollution chemistry. Cem Concr Res 42:539–548. https://doi.org/10.1016/j.cemconres.2011.12.001

Fujishima A, Rao TN, Tryk DA (2000) Titanium dioxide photocatalysis. J Photochem Photobiol C Photochem Rev 1:1–21. https://doi.org/10.1016/j.cemconres.2011.12.001

Fujishima A, Zhang X (2006) Titanium dioxide photocatalysis: present situation and future approaches. C R Chim 9:750–760. https://doi.org/10.1016/j.crci.2005.02.055

Maranhão FL (2009) Método para Redução de Mancha nas Vedações Externas de Edifícios. PhD Thesis, Universidade de São Paulo

Riaz S, Park SJ (2020) An overview of TiO2-based photocatalytic membrane reactors for water and wastewater treatments. J Ind Eng Chem 84:23–41. https://doi.org/10.1016/j.jiec.2019.12.021

Cassar L (2004) Photocatalysis of cementitious materials: clean buildings and clean air. MRS Bull 29:328–331. https://doi.org/10.1557/mrs2004.99

Zahabizadeh B, Rocha Segundo I, Pereira J et al (2023) Photocatalysis of functionalised 3D printed cementitious materials. J Build Eng 70:106373. https://doi.org/10.1016/j.jobe.2023.106373

Diamanti MV, Ormellese M, Pedeferri MP (2008) Characterization of photocatalytic and superhydrophilic properties of mortars containing titanium dioxide. Cem Concr Res 38:1349–1353. https://doi.org/10.1016/j.cemconres.2008.07.003

Austria GC (2015) Argamassa autolimpante para revestimento de fachadas: o efeito das propriedades fotocatalíticas do dióxido de titânio (TiO2). MsC Dissertation, Universidade Federal do Rio Grande do Sul

Treviso JPM (2016) Avaliação da eficiência de autolimpeza em argamassas e pastas contendo TiO2 expostas ao microclima urbano. MsC Dissertation, Universidade Federal do Rio Grande do Sul

De la Rosa JM, Miller AZ, Pozo-Antonio JS et al (2017) Assessing the effects of UVA photocatalysis on soot-coated TiO2-containing mortars. Sci Total Environ 605–606:147–157. https://doi.org/10.1016/j.scitotenv.2017.06.127

Casarin RP (2019) Análise da eficiência da ação autolimpante em diferentes tipos de acabamentos superficiais de argamassas com adição de TiO2. MsC Dissertation, Universidade Federal do Rio Grande do Sul

Piovesan AZ (2009) Estudo sobre a Influência da Adição de Pigmentos em Propriedades de Durabilidade e na Cromaticidade do Concreto de Cimento Portland Branco. MsC Dissertation, Universidade Federal do Rio Grande do Sul

Hatami L, Jamshidi M (2021) Effects of type and duration of pigment milling on mechanical and colorimetric properties of colored self compacting mortars (CSCM). J Build Eng 35:102006. https://doi.org/10.1016/j.jobe.2020.102006

Wang Z, Liu Y, Huang B et al (2014) Progress on extending the light absorption spectra of photocatalysts. Phys Chem Chem Phys 16:2758–2774. https://doi.org/10.1039/C3CP53817F

Diamanti MV, Del Curto B, Ormellese M, Pedeferri MP (2013) Photocatalytic and self-cleaning activity of colored mortars containing TiO2. Constr Build Mater 46:167–174. https://doi.org/10.1016/j.conbuildmat.2013.04.038

Laplaza A, Jimenez-Relinque E, Campos J, Castellote M (2017) Photocatalytic behavior of colored mortars containing TiO2 and iron oxide based pigments. Constr Build Mater 144:300–310. https://doi.org/10.1016/j.conbuildmat.2017.03.146

Janczarek M, Klapiszewski Ł, Jędrzejczak P et al (2022) Progress of functionalized TiO2-based nanomaterials in the construction industry: a comprehensive review. Chem Eng J 430:132062. https://doi.org/10.1016/j.cej.2021.132062

Diamanti MV, Luongo N, Massari S et al (2021) Durability of self-cleaning cement-based materials. Constr Build Mater 280:122442. https://doi.org/10.1016/j.conbuildmat.2021.122442

IBP (Fraunhofer Institute for Building Physics) (2023) WUFI® Pro v6.6 (Version 6.6) manual—non commercial

Pereira C, de Brito J, Silvestre JD (2018) Contribution of humidity to the degradation of façade claddings in current buildings. Eng Fail Anal 90:103–115. https://doi.org/10.1016/j.engfailanal.2018.03.028

Maaroufi M, Belarbi R, Abahri K, Benmahiddine F (2021) Full characterization of hygrothermal, mechanical and morphological properties of a recycled expanded polystyrene-based mortar. Constr Build Mater 301:124310. https://doi.org/10.1016/j.conbuildmat.2021.124310

Krishnan P, Zhang MH, Yu L, Feng H (2013) Photocatalytic degradation of particulate pollutants and self-cleaning performance of TiO2-containing silicate coating and mortar. Constr Build Mater 44:309–316. https://doi.org/10.1016/j.conbuildmat.2013.03.009

American Society for Testing and Materials (2021) ASTM C150/C150M—21: standard specification for Portland Cement

Associação Brasileira de Normas Técnicas (2018) ABNT NBR 16697: cimento Portland—Requisitos

Associação Brasileira de Normas Técnicas (2017) ABNT NBR 16605: cimento Portland e outros materiais em pó—Determinação da massa específica

Associação Brasileira de Normas Técnicas (2021) ABNT NBR 16972: agregados—Determinação da massa unitária e do índice de vazios

Associação Brasileira de Normas Técnicas (2019) ABNT NBR 7215: cimento Portland—Determinação da resistência à compressão de corpos de prova cilíndricos

Zanrosso CD (2016) Avaliação da aplicação de ácidos policarboxílicos como ligantes na imobilização de dióxido de titânio em tecidos de algodão. MSc Dissertation, Universidade Federal do Rio Grande do Sul

Guerra FL (2018) Avaliação da eficiência de nanopartículas de TiO2 no controle do crescimento de fungos filamentosos deteriogênicos em argamassas históricas. PhD Thesis, Universidade Federal do Rio Grande do Sul

González-Sánchez JF, Taşcı B, Fernández JM et al (2021) Improvement of the depolluting and self-cleaning abilities of air lime mortars with dispersing admixtures. J Clean Prod 292:126069. https://doi.org/10.1016/j.jclepro.2021.126069

Dantas SRA, de Oliveira Romano RC, Vittorino F, Loh K (2021) Effects of surface roughness and light scattering on the activation of TiO2 on mortar photocatalytic process. Constr Build Mater 270:121421. https://doi.org/10.1016/j.conbuildmat.2020.121421

Lee HS, Lee JY, Yu MY (2005) Influence of inorganic pigments on the fluidity of cement mortars. Cem Concr Res 35:703–710. https://doi.org/10.1016/j.cemconres.2004.06.010

Associação Brasileira de Normas Técnicas (2003) ABNT NBR NM 248: agregados—Determinação da composição granulométrica

Associação Brasileira de Normas Técnicas (2021) ABNT NBR 16916: agregado miúdo—Determinação da densidade e da absorção de água

Associação Brasileira de Normas Técnicas (2019) ABNT NBR 11768–3: aditivos químicos para concreto de cimento Portland. Parte 3: Ensaios de caracterização

Assaad JJ, Nasr D, Chwaifaty S, Tawk T (2020) Parametric study on polymer-modified pigmented cementitious overlays for colored applications. J Build Eng 27:101009. https://doi.org/10.1016/j.jobe.2019.101009

López A, Tobes JM, Giaccio G, Zerbino R (2009) Advantages of mortar-based design for coloured self-compacting concrete. Cem Concr Compos 31:754–761. https://doi.org/10.1016/j.cemconcomp.2009.07.005

Associação Brasileira de Normas Técnicas (2016) ABNT NBR 13276: argamassa para assentamento e revestimento de paredes e tetos—Determinação do índice de consistência

Associação Brasileira de Normas Técnicas (2005) ABNT NBR 13278: argamassa para assentamento e revestimento de paredes e tetos—Determinação da densidade de massa e do teor de ar incorporado

Associação Brasileira de Normas Técnicas (2005) ABNT NBR 13280: argamassa para assentamento e revestimento de paredes e tetos—Determinação da densidade de massa aparente no estado endurecido

Associação Brasileira de Normas Técnicas (2008) ABNT NBR 15630: argamassa para assentamento e revestimento de paredes e tetos—Determinação do módulo de elasticidade dinâmico através da propagação de onda ultra-sônico

Associação Brasileira de Normas Técnicas (2005) ABNT NBR 13279: argamassa para assentamento e revestimento de paredes e tetos—Determinação da resistência à tração na flexão e à compressão

Associação Brasileira de Normas Técnicas (2005) ABNT NBR 15259: argamassa para assentamento e revestimento de paredes e tetos—Determinação da absorção de água por capilaridade e do coeficiente de capilaridade

American Society for Testing and Materials (2016) ASTM E96/E96M—16: standard test method for water vapor transmission of materials

ASTM International (2005) ASTM G155—05a: standard practice for operating xenon arc light apparatus for exposure of non-metallic materials

ASTM International (2019) ASTM G151—19: standard practice for exposing nonmetallic materials in accelerated test devices that use laboratory light sources

ASTM International (2019) ASTM C1501—19: standard test method for color stability of building construction sealants as determined by laboratory accelerated weathering procedures

Łaźniewska-Piekarczyk B, Szwabowski J (2012) The influence of the type of anti-foaming admixture and superplasticizer on the properties of self-compacting mortar and concrete. J Civ Eng Manag 18:408–415. https://doi.org/10.3846/13923730.2012.698908

Lin X, Pang H, Wei D et al (2021) Effect of superplasticizers with different anchor groups on the properties of cementitious systems. Colloids Surf A Physicochem Eng Asp 630:127207. https://doi.org/10.1016/j.colsurfa.2021.127207

Dantas SRA, Serafini R, de Oliveira Romano RC et al (2019) Influence of the nano TiO2 dispersion procedure on fresh and hardened rendering mortar properties. Constr Build Mater 215:544–556. https://doi.org/10.1016/j.conbuildmat.2019.04.190

Moro C, El Fil H, Francioso V, Velay-Lizancos M (2021) Influence of water-to-binder ratio on the optimum percentage of nano-TiO2 addition in terms of compressive strength of mortars: a laboratory and virtual experimental study based on ANN model. Constr Build Mater 267:120960. https://doi.org/10.1016/j.conbuildmat.2020.120960

Zhao A, Yang J, Yang EH (2015) Self-cleaning engineered cementitious composites. Cem Concr Compos 64:74–83. https://doi.org/10.1016/j.cemconcomp.2015.09.007

Rao S, Silva P, De Brito J (2015) Experimental study of the mechanical properties and durability of self-compacting mortars with nano materials (SiO2 and TiO2). Constr Build Mater 96:508–517. https://doi.org/10.1016/j.conbuildmat.2015.08.049

Ren J, Lai Y, Gao J (2018) Exploring the influence of SiO2 and TiO2 nanoparticles on the mechanical properties of concrete. Constr Build Mater 175:277–285. https://doi.org/10.1016/j.conbuildmat.2018.04.181

Kim S, Seo J, Yoon HN, Lee HK (2022) Exploration of effects of CO2 exposure on the NOx-removal performance of TiO2-incorporated Portland cement evaluated via microstructural and morphological investigation. J Build Eng 45:103609. https://doi.org/10.1016/j.jobe.2021.103609

Isaia GC, Gastaldini ALG, Moraes R (2003) Physical and pozzolanic action of mineral additions on the mechanical strength of high-performance concrete. Cem Concr Compos 25:69–76. https://doi.org/10.1016/S0958-9465(01)00057-9

Lawrence P, Cyr M, Ringot E (2003) Mineral admixtures in mortars: effect of inert materials on short-term hydration. Cem Concr Res 33:1939–1947. https://doi.org/10.1016/S0008-8846(03)00183-2

Kumar R, Bhattacharjee B (2003) Porosity, pore size distribution and in situ strength of concrete. Cem Concr Res 33:155–164. https://doi.org/10.1016/S0008-8846(02)00942-0

Salomão MC, Bauer E, Kazmierczak C (2018) Drying parameters of rendering mortars. Ambiente Construído 18:7–19. https://doi.org/10.1590/s1678-86212018000200239

European Committee for Standardization (2001) EN ISO 12572: building materials: determination of water vapor transmission properties

Cincotto MA, Helene P (1994) Aglomerantes Hidráulicos. In: Mehta P, Monteiro P (eds) Concreto: Estrutura, propriedades e materiais. São Paulo, pp 187–238

Posani M, Veiga MDR, de Freitas VP (2021) Towards resilience and sustainability for historic buildings: a review of envelope retrofit possibilities and a discussion on hygric compatibility of thermal insulations. Int J Archit Herit 15:807–823. https://doi.org/10.1080/15583058.2019.1650133

Veiga MRS (1998) Comportamento de argamassas de revestimento de paredes. Contribuição para o estudo da sua resistência à fendilhação. PhD Thesis, Faculdade de Engenharia da Universidade do Porto

Parracha JL, Borsoi G, Veiga R et al (2022) Durability assessment of external thermal insulation composite systems in urban and maritime environments. Sci Total Environ 849:157828. https://doi.org/10.1016/j.scitotenv.2022.157828

Salomão MCF (2016) Estudo da estrutura das argamassas de revestimento e sua influência nas propriedades de transporte de água. PhD Thesis, Universidade de Brasília

Veiga R, Faria P, van Hees R et al (2023) RILEM TC 277-LHS report: properties of lime-based renders and plasters—discussion of current test methods and proposals for improvement. Mater Struct 56:70. https://doi.org/10.1617/s11527-023-02141-9

Yurtdas I, Leklou N (2021) Effect of re-saturation after drying on hydric and strength behaviour of mortar. Mater Struct 54:186. https://doi.org/10.1617/s11527-021-01780-0

Acknowledgements

This research was funded by CAPES (Coordenação de Aperfeiçoamento de Pessoal de Nível Superior), grant number 88887.702359/2022-00, and CNPq (Conselho Nacional de Desenvolvimento Científico e Tecnológico). The authors would like to thank LAMTAC (Laboratório de Materiais e Tecnologia do Ambiente Construído), LACER (Laboratório de Materiais Cerâmicos), LINCE (Laboratório de Inovação em Cimentos Ecoeficientes), PPGCI (Programa de Pós-Graduação em Engenharia Civil: Construção e Infraestrutura), and UFRGS (Universidade Federal do Rio Grande do Sul).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflict of interest to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bersch, J.D., Masuero, A.B. & Dal Molin, D.C.C. Photocatalytic coloured rendering mortars: effect of TiO2 and iron oxide pigments on the physical, mechanical, hygric, and photoactive behaviour. Mater Struct 56, 146 (2023). https://doi.org/10.1617/s11527-023-02240-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-023-02240-7