Abstract

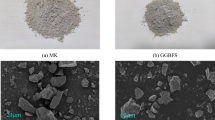

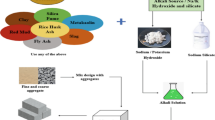

In this study, the fluidity, setting time, and compressive strength for 40%/60% ground granulated blast furnace slag (GGBFS)/metakaolin (MK) based geopolymer synthesis were experimentally investigated. By conducting 120 groups of tests, the effects of three design parameters of the alkaline activator, including the alkaline activator concentration, modulus, and liquid–solid ratio, were systematically analyzed. The test results show that the compressive strength of the GGBFS–MK geopolymer synthesis reaches a maximum value for a modulus of 1.2 or 1.4. Furthermore, according to the experimental results obtained, a series of contour plots for the relationship between the influencing parameters and the workability and mechanical properties for GGBFS–MK geopolymer synthesis are summarized. Then, a mix design method is proposed. Appropriate combinations of the concentration and modulus that can be used to generate a target compressive strength and fluidity are identified from the contour plots for different liquid–solid ratios. This method can be used to determine the mix proportion design for GGBFS–MK geopolymer synthesis that shows a specified compressive strength and working performance.

Similar content being viewed by others

Abbreviations

- C :

-

Concentration of the alkaline activator

- M :

-

Modulus of the alkaline activator

- L/S :

-

Liquid–solid ratio

- MK:

-

Metakaolin

- GGBFS:

-

Ground granulated blast furnace slag

- F d :

-

Target values of fluidity

- F t :

-

Test values of fluidity

- δ d :

-

Target values of compressive strength

- δ t :

-

Test values of compressive strength

References

Schneider M, Romer M, Tschudin M, Bolio H (2011) Sustainable cement production—present and future. Cem Concr Res 41(7):642–650. https://doi.org/10.1016/j.cemconres.2011.03.019

Damtoft JS, Lukasik J, Herfort D, Sorrentino D, Gartner EM (2008) Sustainable development and climate change initiatives. Cem Concr Res 38(2):115–127. https://doi.org/10.1016/j.cemconres.2007.09.008

Adjei S, Elkatatny S, Aggrey WN, Abdelraouf Y (2022) Geopolymer as the future oil-well cement: a review. J Pet Sci Eng. https://doi.org/10.1016/j.petrol.2021.109485

Farhan KZ, Johari MAM, Demirboga R (2020) Assessment of important parameters involved in the synthesis of geopolymer composites: a review. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2020.120276

Kong DLY, Sanjayan JG, Sagoe-Crentsil K (2007) Comparative performance of geopolymers made with metakaolin and fly ash after exposure to elevated temperatures. Cem Concr Res 37(12):1583–1589. https://doi.org/10.1016/j.cemconres.2007.08.021

Duxson P, Provis JL, Lukey GC, van Deventer JSJ (2007) The role of inorganic polymer technology in the development of ‘green concrete.’ Cem Concr Res 37(12):1590–1597. https://doi.org/10.1016/j.cemconres.2007.08.018

Shi C, Jiménez AF, Palomo A (2011) New cements for the 21st century: the pursuit of an alternative to Portland cement. Cem Concr Res 41(7):750–763. https://doi.org/10.1016/j.cemconres.2011.03.016

Shi XS, Zhang C, Liang YC, Luo JQ, Wang XQ, Feng Y, Li YL, Wang QY, Abomohra A (2021) Life cycle assessment and impact correlation analysis of fly ash geopolymer concrete. Materials. https://doi.org/10.3390/ma14237375

Ma C, Zhao B, Guo SL, Long GC, Xie YJ (2019) Properties and characterization of green one-part geopolymer activated by composite activators. J Clean Prod 220:188–199. https://doi.org/10.1016/j.jclepro.2019.02.159

Su M, Zhong Q, Peng H (2021) Regularized multivariate polynomial regression analysis of the compressive strength of slag-metakaolin geopolymer pastes based on experimental data. Constr Build Mater 303:124529. https://doi.org/10.1016/j.conbuildmat.2021.124529

Villaquiran-Caicedo MA, de Gutierrez RM, Gallego NC (2017) A novel MK-based geopolymer composite activated with rice husk ash and KOH: performance at high temperature. Mater De Constr. https://doi.org/10.3989/mc.2017.02316

Frías M, Martínez-Ramírez S, Vigil de la Villa R, García-Giménez R, Sánchez de Rojas MI (2022) New scientific evidence of the effect of high temperatures and long curing times on MK-blended cement paste mineralogy. Cem Concr Res 152:106657. https://doi.org/10.1016/j.cemconres.2021.106657

Jia ZJ, Chen C, Shi JJ, Zhang YM, Sun ZM, Zhang PG (2019) The microstructural change of C-S-H at elevated temperature in Portland cement/GGBFS blended system. Cem Concr Res. https://doi.org/10.1016/j.cemconres.2019.05.018

Bui PT, Huynh TP (2022) Performance and microstructural evaluation of rice husk ash-ground granulated blast furnace slag-CFBC fly ash mixtures produced as an eco-cement. J Mater Civ Eng. https://doi.org/10.1061/(asce)mt.1943-5533.0004119

Tennakoon C, Nicolas RS, Sanjayan JG, Shayan A (2016) Thermal effects of activators on the setting time and rate of workability loss of geopolymers. Ceram Int 42(16):19257–19268. https://doi.org/10.1016/j.ceramint.2016.09.092

Peng H, Li Y, Luo D, Liu Y, Cai CS (2022) Quantitative analysis of reaction degrees and factors influencing alkali-activated metakaolin-GGBFS blend. Constr Build Mater 359:129472. https://doi.org/10.1016/j.conbuildmat.2022.129472

Yip CK, Lukey GC, van Deventer JSJ (2005) The coexistence of geopolymeric gel and calcium silicate hydrate at the early stage of alkaline activation. Cem Concr Res 35(9):1688–1697. https://doi.org/10.1016/j.cemconres.2004.10.042

Khalil MG, Elgabbas F, El-Feky MS, El-Shafie H (2020) Performance of geopolymer mortar cured under ambient temperature. Constr Build Mater 242:118090. https://doi.org/10.1016/j.conbuildmat.2020.118090

Borges PHR, Banthia N, Alcamand HA, Vasconcelos WL, Nunes EHM (2016) Performance of blended metakaolin/blastfurnace slag alkali-activated mortars. Cem Concr Compos 71:42–52. https://doi.org/10.1016/j.cemconcomp.2016.04.008

Bernal SA (2015) Effect of the activator dose on the compressive strength and accelerated carbonation resistance of alkali silicate-activated slag/metakaolin blended materials. Constr Build Mater 98:217–226. https://doi.org/10.1016/j.conbuildmat.2015.08.013

Burciaga-Díaz O, Magallanes-Rivera RX, Escalante-García JI (2013) Alkali-activated slag-metakaolin pastes: strength, structural, and microstructural characterization. J Sustain Cem-Based Mater 2(2):111–127. https://doi.org/10.1080/21650373.2013.801799

Hadi MNS, Farhan NA, Sheikh MN (2017) Design of geopolymer concrete with GGBFS at ambient curing condition using Taguchi method. Constr Build Mater 140:424–431. https://doi.org/10.1016/j.conbuildmat.2017.02.131

Luan C, Shi X, Zhang K, Utashev N, Yang F, Dai J, Wang Q (2021) A mix design method of fly ash geopolymer concrete based on factors analysis. Constr Build Mater 272:121612. https://doi.org/10.1016/j.conbuildmat.2020.121612

Gunasekara C, Atzarakis P, Lokuge W, Law DW, Setunge S (2021) Novel analytical method for mix design and performance prediction of high calcium fly ash geopolymer concrete. Polymers 13(6):900. https://doi.org/10.3390/polym13060900

Singh P, Kapoor K (2022) Development of mix design method based on statistical analysis of different factors for geopolymer concrete. Front Struct Civ Eng 16(10):1315–1335. https://doi.org/10.1007/s11709-022-0853-x

Zahid M, Shafiq N (2020) Effects of sand/fly ash and the water/solid ratio on the mechanical properties of engineered geopolymer composite and mix design optimization. Minerals 10(4):333. https://doi.org/10.3390/MIN10040333

Cho YK, Yoo SW, Jung SH, Lee KM, Kwon SJ (2017) Effect of Na2O content, SiO2/Na2O molar ratio, and curing conditions on the compressive strength of FA-based geopolymer. Constr Build Mater 145:253–260. https://doi.org/10.1016/j.conbuildmat.2017.04.004

Naghizadeh A, Ekolu SO (2019) Method for comprehensive mix design of fly ash geopolymer mortars. Constr Build Mater 202:704–717. https://doi.org/10.1016/j.conbuildmat.2018.12.185

AQSIQ, SAC (2012) Methods for testing uniformity of concrete admixture(GB/T 8077-2012). Standards Press of China, Beijing

AQSIQ, SAC (2011) Test methods for water requirement of normal consistency,setting time and soundness of the portland cement(GB/T 1346-2011). Standards Press of China, Beijing

MOHURD (2009) Standard for test method of basic properties of construction mortar (JGJ/T 70-2009). China Architecture Publishing & Media Co., Ltd., Beijing

Hasnaoui A, Ghorbel E, Wardeh G (2019) Optimization approach of granulated blast furnace slag and metakaolin based geopolymer mortars. Constr Build Mater 198:10–26. https://doi.org/10.1016/j.conbuildmat.2018.11.251

Yang X, Zhu W, Yang Q (2008) The viscosity properties of sodium silicate solutions. J Solut Chem 37(1):73–83. https://doi.org/10.1007/s10953-007-9214-6

Zuhua Z, Xiao Y, Huajun Z, Yue C (2009) Role of water in the synthesis of calcined kaolin-based geopolymer. Appl Clay Sci 43(2):218–223. https://doi.org/10.1016/j.clay.2008.09.003

Park S, Pour-Ghaz M (2018) What is the role of water in the geopolymerization of metakaolin? Constr Build Mater 182:360–370. https://doi.org/10.1016/j.conbuildmat.2018.06.073

Arnoult M, Perronnet M, Autef A, Rossignol S (2018) How to control the geopolymer setting time with the alkaline silicate solution. J Non-Cryst Solids 495:59–66. https://doi.org/10.1016/j.jnoncrysol.2018.02.036

Yifeng L, Kejin W, Xuhao W, Sudong H (2019) Effects of mix design parameters on heat of geopolymerization, set time, and compressive strength of high calcium fly ash geopolymer. Constr Build Mater 228:116763. https://doi.org/10.1016/j.conbuildmat.2019.116763

Duran Atiş C, Bilim C, Çelik Ö, Karahan O (2009) Influence of activator on the strength and drying shrinkage of alkali-activated slag mortar. Constr Build Mater 23(1):548–555. https://doi.org/10.1016/j.conbuildmat.2007.10.011

Mustafa AM, AB H, K M, B A (2012) Effect of Na2SiO3/NaOH ratios and NaOH molarities on compressive strength of fly-ash-based geopolymer. ACI Mater J 109(5):503–508

Ruiz-Santaquiteria C, Skibsted J, Fernández-Jiménez A, Palomo A (2012) Alkaline solution/binder ratio as a determining factor in the alkaline activation of aluminosilicates. Cem Concr Res 42(9):1242–1251. https://doi.org/10.1016/j.cemconres.2012.05.019

Ling Y, Wang K, Wang X, Hua S (2019) Effects of mix design parameters on heat of geopolymerization, set time, and compressive strength of high calcium fly ash geopolymer. Constr Build Mater 228:116763. https://doi.org/10.1016/j.conbuildmat.2019.116763

Bignozzi MC, Manzi S, Natali ME, Rickard WDA, van Riessen A (2014) Room temperature alkali activation of fly ash: the effect of Na2O/SiO2 ratio. Constr Build Mater 69:262–270. https://doi.org/10.1016/j.conbuildmat.2014.07.062

Khedmati M, Alanazi H, Kim Y-R, Nsengiyumva G, Moussavi S (2018) Effects of Na2O/SiO2 molar ratio on properties of aggregate-paste interphase in fly ash-based geopolymer mixtures through multiscale measurements. Constr Build Mater 191:564–574. https://doi.org/10.1016/j.conbuildmat.2018.10.024

Reddy KC, Gudur C, Subramaniam KVL (2020) Study on the influences of silica and sodium in the alkali-activation of ground granulated blast furnace slag. Constr Build Mater 257:119514. https://doi.org/10.1016/j.conbuildmat.2020.119514

Buchwald A, Zellmann HD, Kaps CJJoN-CS (2011) Condensation of aluminosilicate gels—model system for geopolymer binders. J Non-Cryst Solids 357(5):1376–1382. https://doi.org/10.1016/j.jnoncrysol.2010.12.036

Davidovits J (2005) Geopolymer chemistry and sustainable development, Geopolymer green chemistry and sustainable development solutions, Geopolymer 2005 conference

Acknowledgements

The work was supported by the National Natural Science Foundation of China (Grant No. 51878068), the Open Fund of Key Laboratory of Safety Control of Bridge Engineering, Ministry of Education (Changsha University of Science & Technology) (Grant No. 18KB02) and the Basic Ability Improvement Project of Young and Middle-aged Teachers in Colleges and Universities in Guangxi (Grant No. 2018KY0315).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhong, Q., Su, M., Tian, X. et al. Workability and mechanical properties for GGBFS–MK geopolymer synthesis: influencing factor analysis and a mix design method. Mater Struct 56, 144 (2023). https://doi.org/10.1617/s11527-023-02232-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-023-02232-7