Abstract

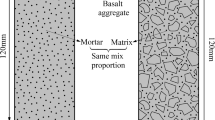

Ultra-high performance mortar (UHPM) has been proposed to replace conventional mortar (CM) as it can improve the compressive performance of stone masonry structure. To investigate performance features such as failure modes, load-versus deformation and ultimate compressive strength, eighteen UHPM and CM stone masonry specimens were tested under axial loading with mortar type, fiber type, mortar thickness and stone block surface condition as the main parameters. The test results indicate that for UHPM specimens, the primary cause of failure is the cracking of stone blocks rather than the mortar joints. And the cracking and ultimate compressive strength is 182.1% and 245.3% higher respectively compared with that of the CM ones. mechanism possible explanation is that stone blocks in stone masonry with UHPM are in a tri-axial compression due to the confinement effect of UHPM material which possesses high elastic modulus and low Poisson's ratio. UHPC without fibers recommended for stone masonry structures as the theoretically positive effects of steel and PVA fibers on UHPC did not show up in this experiment. The artificial sand blasting treatment on stone surface exerts little effect on the compressive performance of UHPC stone masonry. Based on the test results, a new formula of EC6 is recalculated and the ratio between recalculated and test values is 0.97 with a variance of 0.07. However, for the equation used to predict the compressive strength of UHPM stone masonry is still need to improvement.

Similar content being viewed by others

References

García D, San-José JT, Garmendia L, Larrinaga P (2012) Comparison between experimental values and standards on natural stone masonry mechanical properties. Constr Build Mater 28(1):444–449. https://doi.org/10.1016/j.conbuildmat.2011.08.012

García D, San-José JT, Garmendia L, San-Mateos R (2012) Experimental study of traditional stone masonry under compressive load and comparison of results with design codes. Mater Struct 45(7):995–1006. https://doi.org/10.1617/s11527-011-9812-z

Vasconcelos G, Lourenço PB (2009) Experimental characterization of stone masonry in shear and compression. Constr Build Mater 23(11):3337–3345. https://doi.org/10.1016/j.conbuildmat.2009.06.045

Rodríguez Pérez I, Vasconcelos G, Lourenço PB et al (2021) Physical-mechanical characterization of limestones from Yucatan churches, Mexico. J Build Eng 44:102895. https://doi.org/10.1016/j.jobe.2021.102895

Bernat-Maso E, Escrig C, Aranha CA, Gil L (2014) Experimental assessment of textile reinforced sprayed mortar strengthening system for brickwork wallettes. Constr Build Mater 50:226–236. https://doi.org/10.1016/j.conbuildmat.2013.09.031

Zimmermann T, Strauss A, Bergmeister K (2011) Structural behavior of low-and normal-strength interface mortar of masonry. Mater Struct 45(6):829–839. https://doi.org/10.1617/s11527-011-9801-2

Thaickavil NN, Thomas J (2018) Behaviour and strength assessment of masonry prisms. Case Stud Constr Mater 8:23–38. https://doi.org/10.1016/j.cscm.2017.12.007

Kaushik HB, Rai DC, Jain SK (2007) Stress–strain characteristics of clay brick masonry under uniaxial compression. J Mater Civ Eng 19(9):728–739. https://doi.org/10.1061/(ASCE)0899-1561(2007)19:9(728)

Singh SB, Munjal P (2017) Bond strength and compressive stress-strain characteristics of brick masonry. J Build Eng 9:10–16. https://doi.org/10.1016/j.jobe.2016.11.006

Zhou Q, Wang F, Zhu F et al (2017) Stress–strain model for hollow concrete block masonry under uniaxial compression. Mater Struct 50(106):1–12. https://doi.org/10.1617/s11527-016-0975-5

Nalon GH, Santos CFR, Pedroti LG (2020) Strength and failure mechanisms of masonry prisms under compression, flexure and shear: components’ mechanical properties as design constraints. J Build Eng 28:10103. https://doi.org/10.1016/j.jobe.2019.101038

PR China Minister of China. JTG D61-2005: Code for Design of Highway Masonry Brideges and Culverts. China Communication Press;2005

PR China Minister of China. GB 50003-2011: Code for Design of Masonry Structures. Chinese Standard Press; 2011

Rao KVM, Reddy BVV, Jagadish KS (1997) Strength characteristics of stone masonry. Mater Struct 30:233–237. https://doi.org/10.1007/BF02486181

ASTM C-270. Standard specification for mortar for unit masonry. ASTM International, West Conshohocken; 2014

Xu XL, Guo ZX, Cai ZL et al (2017) Experimental study on performance of stone masonry walls under axial compression. J Build Struct 38(12):152–157. https://doi.org/10.14006/j.jzjgxb.2017.12.017

Cominelli S, Giuriani E, Marini A (2017) Mechanisms governing the compressive strength of unconfined and confined rubble stone masonry. Mater Struct 50:10. https://doi.org/10.1617/s11527-016-0905-6

Li CY (2015) Research on the basic mechanical properties of block stone masonry. Postgraduate thesis. Southeast University, Nan Jing, China

Zahra T, Dhanasekar M (2016) Prediction of masonry compressive behavior using a damage mechanics inspired modelling method. Constr Build Mater 109:128–138. https://doi.org/10.1016/j.conbuildmat.2016.01.048

Drougkas A, Roca P, Molins C (2015) Compressive strength and elasticity of pure lime mortar masonry. Mater Struct 49:983–999. https://doi.org/10.1617/s11527-015-0553-2

Yao X, Liang B, Zhang H (2011) Typical brick masonry walls reinforced with high-strength mortar and steel bars in the horizontal joints. Adv Struct Eng 24(12):2767–2779. https://doi.org/10.1177/136943322110122

Sandin K (1995) Mortars for masonry and rendering choice and application. Build Issues 7:3–18

Deng M, Li T, Zhang Y (2020) Compressive performance of masonry columns confined with highly ductile fiber reinforced concrete (HDC). Constr Build Mater 254:119264. https://doi.org/10.1016/j.conbuildmat.2020.119264

Islam MT, Chan R, Bindiganavile V (2012) Stress rate sensitivity of stone masonry units bound with fibre reinforced hydraulic lime mortar. Mater Struct 45:765–776. https://doi.org/10.1617/s11527-011-9796-8

Wang PM, Xu Q, Stark J (2001) Mechanical properties of styrene-butadiene emulsion modified cement mortar used for repair of bridge surface. J Build Mater 4(1):1–6

Yi WJ, Nong JL, Hang ZY et al (2011) Research on long-time interfacial bonding performance of polymer modified cement-based mortars. Bull Chin Ceram Soc. https://doi.org/10.16552/j.cnki.issn1001-1625.2011.04.020

Bosiljkov V, Zarnic R, Bokan V (2000) Shear tests of the URM panels made from different types of mortar experimental study. In: 12th international brick/block masonry conference, Madrid, Spain, pp 112–119

Alecci V, Fagone M, Rotunno T et al (2013) Shear strength of brick masonry walls assembled with different types of mortar. Constr Build Mater 40:1038–1045. https://doi.org/10.1016/j.conbuildmat.2012.11.107

Zhao W, Li DX, Li QH (2016) Review of polymer modified mortar. Mater Rep 24(11):136–140

Chen BC, Su JZ, Li C (2017) An ultra-high performance mortar for building joints. China, 2017100666139

Li Cong, Chen Baochun, Su Jiazhan, et al (2017) Experimental study of ultra-high performance mortar masonry short columns under axial loads. In: Proceedings of the AFGC-ACI_fib_RILEM international conference on ultra-high performance fibre-reinforced concrete, Volumne II, RILEM Publication, pp 605–614

McNary WS, Abrams DP (1985) Mechanics of masonry compression. J Struct Eng 111(4):857–870. https://doi.org/10.1061/(ASCE)0733-9445(1985)111:4(857)

Berto L, Saetta A, Scotta R et al (2005) Failure mechanism of masonry prism loaded in axial compression: computational aspects. Mater Struct 38:249–256. https://doi.org/10.1007/BF02479350

PR China Minister of China. JGJ 98-2010: specification for mix proportion design of masonry mortar. Chinese Standard Press 2010

PR China Minister of China. JGJ/T 70-2009: Standard for test method of basic properties of construction mortar 2009

Ji T, Chen BC, Zhuang YZ et al (2011) Effects of Sand Particle Size and Gradation on Strength of Reactive Powder Concrete. Adv Mater Res 261–263:208–211. https://doi.org/10.4028/www.scientific.net/AMR.261-263.208

PR China Minister of China. GB175-2020: Common portland cement 2020

PR China Minister of China. GB/T 27690-2011: Silica fume for cement mortar and concrete 2011

PR China Minister of China. GB/T 14684-2022: Sand for construction; 2022

Vonk RA (1992) “Softening of concrete loaded in compression”, Dissertation, (Eindhoven University of Technology, Eindhoven. The Netherlands. https://doi.org/10.6100/IR375705

Hendry AW Structural masonry, 2nd Edn. (MacMillan Press LTD, London, 1998. https://doi.org/10.1007/978-1-349-14827-1

Eurocode 6. Design of masonry structures. European Committee for Standardization, 2005, pp 15–32

AS 3700-2018. Masonry structures. Australian Standard Association, 2018: 15–48

ACI 530.1-02. Commentary on specification for masonry structures. Manual of Concrete Practice, Detroit, USA; 2002

Acknowledgements

This project was sponsored in part by the National Key R&D Program of China (2018YFC0705400), Project funded by China Postdoctoral Science Foundation (2023T160138), Guangxi University High-level Talent Funding Project (A3030051017, A3030051026) and Guangxi Zhuang autonomous region Postdoctoral Innovative Talent Support Program (T3030097963). Their supports are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

No potential conflict of interest was reported by the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, C., Chen, B., Sennah, K. et al. Experimental study on axial compressive behavior of stone masonry with ultra-high performance mortar. Mater Struct 56, 124 (2023). https://doi.org/10.1617/s11527-023-02215-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-023-02215-8