Abstract

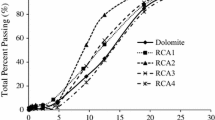

The fracture response of concrete with 30%, 60%, and 100% replacement of natural coarse aggregate with recycled concrete aggregate (RCA) is evaluated. An inverse analysis is performed on the measured fracture test response, assuming a multi-linear stress-crack separation (σ − w) relationship. The cohesive σ − w relationship indicates a decrease in the tensile strength and lower cohesive stress with RCA replacement levels higher than 30%. The crack depth established from digital image correlation is larger for a given crack mouth opening displacement in concrete with RCA. There is an increase in the area of the fractured surface with increasing RCA content. However, there is a consistent decrease in fracture energy with increasing RCA content. The microscopic examination reveals the existence of weak planes along with RCA interfaces with new mortar and pre-existing fracture planes in the aggregate. The increase in the surface area with RCA is attributed to weak planes around the RCA and pre-existing cracks in the aggregate, which creates a more tortuous path. There is thus an increase in the fracture surface area, a decrease in the fracture energy, a reduction in the cohesive stress transfer with crack opening, and a larger crack depth for a given crack opening in concrete with increasing RCA substitution.

Similar content being viewed by others

References

The International Federation for Structural Concrete (fib) (2011) Model code 2010

IS 456 (2000) Concrete, plain and reinforced. Bureau of Indian Standards, New Delhi, pp 1–114

ACI 318R (2014) ACI 318R-14.pdf

Putri DD ASTM C33/C33M-18 Standard specification for concrete aggregates 1

Rilem TC (1994) 121-DRG. Specifications for concrete with recycled aggregates. Mater Struct 27:557–559

Belén G, Fernando M, Isabel M, Javier E (2009) Structural shear behaviour of recycled concrete with silica fume. Constr Build Mater 23:3406–3410. https://doi.org/10.1016/j.conbuildmat.2009.06.035

Ghorbel E, Wardeh G (2017) Influence of recycled coarse aggregates incorporation on the fracture properties of concrete. Constr Build Mater 154:51–60. https://doi.org/10.1016/j.conbuildmat.2017.07.183

Marinkovic B, Tošic N, Ignjatovic IS (2017) Shear behaviour of recycled aggregate concrete beams with and without shear reinforcement. Eng Struct 141:386–401. https://doi.org/10.1016/j.engstruct.2017.03.026

Adams MP, Fu T, Guerra A et al (2016) Cracking susceptibility of concrete made with coarse recycled concrete aggregates. Constr Build Mater 102:802–810. https://doi.org/10.1016/j.conbuildmat.2015.11.022

Ceia F, Raposo J, Guerra M et al (2016) Shear strength of recycled aggregate concrete to natural aggregate concrete interfaces. Constr Build Mater 109:139–145. https://doi.org/10.1016/j.conbuildmat.2016.02.002

Ahmad S, Tech WM, Singh B (2016) Shear transfer strength of normal and high-strength recycled aggregate concrete—an experimental investigation. Constr Build Mater 125:29–40. https://doi.org/10.1016/j.conbuildmat.2016.08.022

Arezoumandi M, Smith A, Volz JS, Khayat KH (2015) An experimental study on flexural strength of reinforced concrete beams with 100% recycled concrete aggregate. Eng Struct 88:154–162. https://doi.org/10.1016/j.engstruct.2015.01.043

Arezoumandi M, Smith A, Volz JS, Khayat KH (2014) An experimental study on shear strength of reinforced concrete beams with 100% recycled concrete aggregate. Constr Build Mater 53:612–620. https://doi.org/10.1016/j.conbuildmat.2013.12.019

Pantini S, Rigamonti L (2020) Is selective demolition always a sustainable choice? Waste Manag 103:169–176. https://doi.org/10.1016/j.wasman.2019.12.033

Pedro D, De Brito J, Evangelista L (2014) Influence of the use of recycled concrete aggregates from different sources on structural concrete. Constr Build Mater 71:141–151. https://doi.org/10.1016/j.conbuildmat.2014.08.030

Musiket K, Rosendahl M, Xi Y (2016) Fracture of recycled aggregate concrete under high loading rates. J Mater Civ Eng 28:04016018. https://doi.org/10.1061/(asce)mt.1943-5533.0001513

Dhir RK, de Brito J, Silva RV, Lye CQ (2019) Properties and composition of recycled aggregates. https://doi.org/10.1016/B978-0-08-100985-7.00005-4

Kim Y, Hanif A, Kazmi SMS et al (2018) Properties enhancement of recycled aggregate concrete through pretreatment of coarse aggregates: comparative assessment of assorted techniques. J Clean Prod 191:339–349. https://doi.org/10.1016/j.jclepro.2018.04.192

Biswal US, Dinakar P (2021) A mix design procedure for fly ash and ground granulated blast furnace slag based treated recycled aggregate concrete. Clean Eng Technol. https://doi.org/10.1016/j.clet.2021.100314

Behera M, Bhattacharyya SK, Minocha AK et al (2014) Recycled aggregate from C&D waste & its use in concrete—a breakthrough towards sustainability in construction sector: a review. Constr Build Mater 68:501–516. https://doi.org/10.1016/j.conbuildmat.2014.07.003

Fallahnejad H, Davoodi MR, Nikbin IM (2021) The influence of aging on the fracture characteristics of recycled aggregate concrete through three methods. Struct Concr 22:E74–E93. https://doi.org/10.1002/suco.202000119

Thomas C, de Brito J, Cimentada A, Sainz-Aja JA (2020) Macro- and micro- properties of multi-recycled aggregate concrete. J Clean Prod. https://doi.org/10.1016/j.jclepro.2019.118843

Abdollahnejad Z, Mastali M, Falah M et al (2019) Construction and demolition waste as recycled aggregates in alkali-activated concretes. Materials. https://doi.org/10.3390/ma12234016

IS: 2386-4 (2016) Methods of test for aggregates for concrete, pa 4: mechanical properties. Bureau of Indian Standards, New Delhi, pp 1–37

IS:383-2016 (2016) Indian standard coarse and fine aggregate for concrete- specification. Bureau of Indian Standards, New Delhi, India, pp 1–21

Sutton MA, McNeill SR, Jang J, Babai M (1988) Effects of subpixel image restoration on digital correlation error estimates. Opt Eng. https://doi.org/10.1117/12.7976778

Chu TC, Ranson WF, Sutton MA (1985) Applications of digital-image-correlation techniques to experimental mechanics. Exp Mech 25:232–244. https://doi.org/10.1007/BF02325092

Sutton M, Wolters W, Peters W et al (1983) Determination of displacements using an improved digital correlation method. Image Vis Comput 1:133–139. https://doi.org/10.1016/0262-8856(83)90064-1

Bruck HA, McNeill SR, Sutton MA, Peters WH (1989) Digital image correlation using Newton-Raphson method of partial differential correction. Exp Mech 29:261–267. https://doi.org/10.1007/BF02321405

Schreier HW, Sutton MA (2002) Systematic errors in digital image correlation due to undermatched subset shape functions. Exp Mech 42:303–310. https://doi.org/10.1177/001448502321548391

Reddy CK, Subramaniam KVL (2017) Analysis for multi-linear stress-crack opening cohesive relationship: application to macro-synthetic fiber reinforced concrete. Eng Fract Mech 169:128–145. https://doi.org/10.1016/j.engfracmech.2016.11.015

Gali S, Subramaniam KVL (2018) Multi-linear stress-crack separation relationship for steel fiber reinforced concrete: analytical framework and experimental evaluation. Theor Appl Fract Mech 93:33–43. https://doi.org/10.1016/j.tafmec.2017.06.018

Bhogone MV, Subramaniam KVL (2021) Early-age tensile constitutive relationships for steel and polypropylene fiber reinforced concrete. Eng Fract Mech 244:1–16. https://doi.org/10.1016/j.engfracmech.2021.107556

de Oliveira e Sousa JLA, Gettu R (2006) Determining the tensile stress-crack opening curve of concrete by inverse analysis. J Eng Mech 132:141–148. https://doi.org/10.1061/(asce)0733-9399(2006)132:2(141)

Reddy KC, Subramaniam KVL (2017) Experimental investigation of crack propagation and post-cracking behaviour in macrosynthetic fibre reinforced concrete. Mag Concr Res 69:467–478. https://doi.org/10.1680/jmacr.16.00396

Kou SC, Poon CS (2012) Enhancing the durability properties of concrete prepared with coarse recycled aggregate. Constr Build Mater 35:69–76. https://doi.org/10.1016/j.conbuildmat.2012.02.032

Shi C, Li Y, Zhang J et al (2016) Performance enhancement of recycled concrete aggregate: a review. J Clean Prod 112:466–472. https://doi.org/10.1016/j.jclepro.2015.08.057

Spaeth V, Djerbi Tegguer A (2013) Improvement of recycled concrete aggregate properties by polymer treatments. Int J Sustain Built Environ 2:143–152. https://doi.org/10.1016/j.ijsbe.2014.03.003

Tsujino M, Noguchi T, Tamura M et al (2007) Application of conventionally recycled coarse aggregate to concrete structure by surface modification treatment. J Adv Concr Technol 5:13–25. https://doi.org/10.3151/jact.5.13

Liang JF, Yang ZP, Yi PH, Wang JB (2015) Mechanical properties of recycled fine glass aggregate concrete under uniaxial loading. Comput Concr 16:275–285. https://doi.org/10.12989/CAC.2015.16.2.275

Qiu J, Tng DQS, Yang EH (2014) Surface treatment of recycled concrete aggregates through microbial carbonate precipitation. Constr Build Mater 57:144–150. https://doi.org/10.1016/j.conbuildmat.2014.01.085

Author information

Authors and Affiliations

Contributions

SC: investigation; data curation; formal analysis; writing—original draft. KVLS: conceptualization; supervision; funding acquisition; project administration; review and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chakraborty, S., Subramaniam, K.V.L. Evaluation of cracking and cohesive fracture response in recycled aggregate concrete. Mater Struct 56, 130 (2023). https://doi.org/10.1617/s11527-023-02193-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-023-02193-x