Abstract

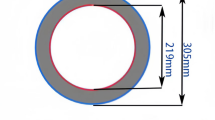

In this study, a new empirical Square-Box test was employed to evaluate the homogeneous flow performance of fiber-reinforced self-consolidating concrete (FR-SCC) under confined-flow conditions that are typical of repair applications. The Square-Box set-up consisted of a closed-circuit box, providing 2.4-m flow distance and a closed-surface cross section of 100-mm width and 200-mm height, equipped with 0 and 4 rows of reinforcing bar grids with 45-mm clear spacing. The flow performance was assessed in terms of dynamic stability and passing ability. The investigated mixtures were considered as diphasic suspensions of fiber-coarse aggregate (F-A > 5 mm) in suspending mortars containing particles finer than 5 mm. According to the experimental results, the dynamic segregation and blocking indices of the investigated mixtures were found in good agreements with characteristics of F-A combination and rheology of mortar. The investigated mixtures exhibited significantly higher blocking indices through the Square-Box set-up compared to those obtained using the L-Box test. Furthermore, the characteristics of F-A and rheology of mortar showed opposite effects on dynamic segregation assessed using Square-Box and conventional T-Box set-ups. Under confined flow conditions, higher dynamic segregation led to more dissimilar compressive strength values at different flow distances through the proposed Square-Box set-up. A new filling ability classification was established based on the experimental dynamic stability and passing ability results of the proposed empirical test.

Similar content being viewed by others

References

Wang J, Dai Q, Si R, Ma Y, Guo S (2020) Fresh and mechanical performance and freeze-thaw durability of steel fiber-reinforced rubber self-compacting concrete (SRSCC). J Clean Prod 277:123180. https://doi.org/10.1016/j.jclepro.2020.123180

Cattaneo S, Giussani F, Mola F (2012) Flexural behaviour of reinforced, prestressed and composite self-consolidating concrete beams. Constr Build Mater 36:826–837. https://doi.org/10.1016/j.conbuildmat.2012.06.001

Khayat KH, Kassimi F, Ghoddousi P (2014) Mixture design and testing of fiber-reinforced self-consolidating concrete. ACI Mater J 111(2):143–152. https://doi.org/10.14359/51686722

Ferrara L, Bamonte P, Caverzan A, Musa A, Sanal I (2012) A comprehensive methodology to test the performance of Steel Fibre Reinforced Self-Compacting Concrete (SFR-SCC). Constr Build Mater 37:406–424. https://doi.org/10.1016/j.conbuildmat.2012.07.057

Dhonde HB, Mo YL, Hsu TTC, Vogel J (2007) Fresh and hardened properties of self-consolidating fiber-reinforced concrete. ACI Mater J 104(5):491–500. https://doi.org/10.14359/18905

ASTM C1399/C1399M-10 (2015) Standard test method for obtaining average residual-strength of fiber-reinforced concrete, West Conshohocken, PA; ASTM International. https://dx.doi.org/https://doi.org/10.1520/C1399_C1399M-10R15

ASTM C1609/C1609M-19a (2020) Standard test method for flexural performance of fibre-reinforced concrete (Using Beam With Third Point Loading), West Conshohocken, PA; ASTM International. https://dx.doi.org/https://doi.org/10.1520/C1609_C1609M-19A

Song Q, Yu R, Shui Z, Wang X, Rao S, Lin Z (2018) Optimization of fibre orientation and distribution for a sustainable ultra-high performance fibre reinforced concrete (UHPFRC): experiments and mechanism analysis. Constr Build Mater 169:8–19. https://doi.org/10.1016/j.conbuildmat.2018.02.130

Zhang L, Zhao J, Fan C, Wang Z (2020) Effect of surface shape and content of steel fiber on mechanical properties of concrete. Adv Civ Eng 2020:8834507. https://doi.org/10.1155/2020/8834507

Sorelli LG, Meda A, Plizzari GA (2006) Steel fiber concrete slabs on ground: A structural matter. ACI Struct J 103(4):551–558. https://doi.org/10.14359/16431

Di Prisco M, Mauri M, Scola M (2006) A new design for stabilizing ground slopes, In: Proceedings of the 2nd fib congress, Napoli, Italy, ID 4-1 on CD-ROM. http://hdl.handle.net/11311/536592

El-Dieb AS, Reda Taha MM (2012) Flow characteristics and acceptance criteria of fiber-reinforced self-compacted concrete (FR-SCC). Constr Build Mater 27(1):585–596. https://doi.org/10.1016/j.conbuildmat.2011.07.004

Žirgulis G, Švec O, Geiker MR, Cwirzen A, Kanstad T (2016) Influence of reinforcing bar layout on fibre orientation and distribution in slabs cast from fibre-reinforced self-compacting concrete (FRSCC). Struct Concr 17(2):245–256. https://doi.org/10.1002/suco.201500064

Boulekbache B, Hamrat M, Chemrouk M, Amziane S (2010) Flowability of fibre-reinforced concrete and its effect on the mechanical properties of the material. Constr Build Mater 24(9):1664–1671. https://doi.org/10.1016/j.conbuildmat.2010.02.025

Jasiūnienė E, Cicėnas V, Grigaliūnas P, Rudžionis Ž, Navickas AA (2018) Influence of the rheological properties on the steel fibre distribution and orientation in self-compacting concrete. Mater Struct 51:103. https://doi.org/10.1617/s11527-018-1231-y

Yoo DY, Zi G, Kang ST, Yoon YS (2015) Biaxial flexural behavior of ultra-high-performance fiber-reinforced concrete with different fiber lengths and placement methods. Cem Concr Compos 63:51–66. https://doi.org/10.1016/j.cemconcomp.2015.07.011

Hwang S-D, Khayat KH (2008) Effect of mixture composition on restrained shrinkage cracking of self-consolidating concrete used in repair. ACI Mater J 105(5):498–508. https://doi.org/10.14359/19980

Kassimi F, El-Sayed AK, Khayat KH (2014) Performance of fiber-reinforced self-consolidating concrete for repair of reinforced concrete beams. ACI Struct J 111(6):1277–1286. https://doi.org/10.14359/51687031

Safdar M, Matsumoto T, Kakuma K (2016) Flexural behavior of reinforced concrete beams repaired with ultra-high performance fiber reinforced concrete (UHPFRC). Compos Struct 157:448–460. https://doi.org/10.1016/j.compstruct.2016.09.010

Issa CA, Assaad JJ (2017) Stability and bond properties of polymer-modified self-consolidating concrete for repair applications. Mater Struct 50(1):28. https://doi.org/10.1617/s11527-016-0921-6

Diab AM, Abd Elmoaty AEM, Tag Eldin MR (2017) Slant shear bond strength between self compacting concrete and old concrete. Constr Build Mater 130:73–82. https://doi.org/10.1016/j.conbuildmat.2016.11.023

Arezoumandi M, Wirkman C, Volz JS (2018) Performance of fiber-reinforced self-consolidating concrete for repair of bridge substructures. Structure 15:320–328. https://doi.org/10.1016/j.istruc.2018.07.015

Kassimi F, El-Sayed AK, Khayat KH (2021) Flexural behavior of fiber-reinforced SCC for monolithic and composite beams. J Adv Concr Technol 19(8):937–949. https://doi.org/10.3151/jact.19.937

Abed MA, Fořt J, Naoulo A, Essa A (2021) Influence of polypropylene and steel fibers on the performance and crack repair of self-compacting concrete. Materials 14(19):5506. https://doi.org/10.3390/ma14195506

Voigt T, Bui VK, Shah SP (2004) Drying shrinkage of concrete reinforced with fibers and welded-wire fabric. ACI Mater J 101(3):233–241. https://doi.org/10.14359/13119

Koura BIO, Hosseinpoor M, Yahia A (2020) Coupled effect of fine mortar and granular skeleton characteristics on dynamic stability of self-consolidating concrete as a diphasic material. Constr Build Mater 263:120131. https://doi.org/10.1016/j.conbuildmat.2020.120131

Hosseinpoor M, Koura BIO, Yahia A (2021) Rheo-morphological investigation of static and dynamic stability of self-consolidating concrete: a biphasic approach. Cem Concr Compos 121:104072. https://doi.org/10.1016/j.cemconcomp.2021.104072

Hosseinpoor M, Koura BIO, Yahia A (2021) New diphasic insight into the restricted flowability and granular blocking of self-consolidating concrete: effect of morphological characteristics of coarse aggregate on passing ability of SCC. Constr Build Mater 308:125001. https://doi.org/10.1016/j.conbuildmat.2021.125001

Esmaeilkhanian B, Feys D, Khayat KH, Yahia A (2014) New test method to evaluate dynamic stability of self-consolidating concrete. ACI Mater J 111(3):299–307. https://doi.org/10.14359/51686573

ASTM C1621/C1621M-17 (2017) Standard test method for passing ability of self-consolidating concrete by J-Ring. West Conshohocken, PA; ASTM International. https://doi.org/10.1520/C1621_C1621M-17

EFNARC, European Project Group (2005) The European guidelines for self-compacting concrete: specification, production and use

ASTM C1611/C1611M-18 (2018) Standard Test method for slump flow of self-consolidating concrete. West Conshohocken, PA; ASTM International. https://doi.org/10.1520/C1611_C1611M-18

Kuroiwa S, Matsuoka Y, Hayakawa M, Shindoh T (1993) Application of super workable concrete to construction of a 20-story building. ACI Symposium Publication vol 140, p 147–162

Khayat KH (1999) Workability, testing, and performance of self-consolidating concrete. ACI Mater J 96(3):346–353. https://doi.org/10.14359/632

Nordtest (1994) Method (NT BUILD 427) for Fresh Concrete: Compactibility with IC-tester (Intensive Compaction Tester) Proj. 1005-91, Nord. Scand. Inst. 1-4, ISSN 0283-7153. www.nordtest.org

Aïssoun BM (2011) Étude de l'influence des caractéristiques des granulats sur la performance des bétons fluides à rhéologie adaptée (in French). M.Sc. Thesis, Université de Sherbrooke. http://savoirs.usherbrooke.ca/handle/11143/1590

Nouri N, Hosseinpoor M, Yahia A, Khayat KH (2022) Coupled effect of fiber and granular skeleton characteristics on packing density of fiber-aggregate mixtures. Constr Build Mater 342:127932. https://doi.org/10.1016/j.conbuildmat.2022.127932

Hosseinpoor M, Koura BIO, Yahia A, Kadri EH (2021) Diphasic investigation of the visco-elastoplastic characteristics of highly flowable fine mortars. Constr Build Mater 270:121425. https://doi.org/10.1016/j.conbuildmat.2020.121425

Hosseinpoor M, Koura BIO, Yahia A (2021) Rheo-morphological investigation of Reynolds dilatancy and its effect on pumpability of self-consolidating concrete. Cem Concr Compos 117:103912. https://doi.org/10.1016/j.cemconcomp.2020.103912

Esmaeilkhanian B, Khayat KH, Yahia A, Feys D (2014) Effects of mix design parameters and rheological properties on dynamic stability of self-consolidating concrete. Cem Concr Compos 54:21–28. https://doi.org/10.1016/j.cemconcomp.2014.03.001

Acknowledgements

The authors wish to thank the financial support of the National Science and Engineering Research Council of Canada (NSERC) and the eight industrial partners participating in the NSERC Industrial Research Chair (IRC) on Development of Flowable Concrete with Adapted Rheology and Their Application in Concrete Infrastructures, held by Professor Ammar Yahia at the Université de Sherbrooke.

Author information

Authors and Affiliations

Contributions

NN: Conceptualization, Methodology, Software, Validation, Formal analysis, Investigation, Data curation, and Writing–Original draft. MH: Conceptualization, Methodology, Software, Validation, Formal analysis, Investigation, Resources, Data curation, Writing–Review original and edited drafts, and Supervision. AY: Conceptualization, Methodology, Formal analysis, Investigation. Resources, Writing–Review original and edited Drafts, Supervision, and Project administration, KHK: Conceptualization, Methodology, Formal analysis, Investigation, Writing–Review original and edited drafts, Supervision, and Project administration.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nouri, N., Hosseinpoor, M., Yahia, A. et al. Homogenous flow performance of steel fiber-reinforced self-consolidating concrete for repair applications: developing a new empirical set-up. Mater Struct 55, 223 (2022). https://doi.org/10.1617/s11527-022-02056-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-022-02056-x