Abstract

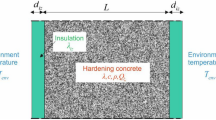

The durability of massive concrete structures may be compromised by delayed ettringite formation and thermal cracking. Designers have sought to develop alternative mix designs to control these durability issues, the efficacy of which depends on the adiabatic temperature rise of the mixtures. This contribution introduces a methodology for the prediction of the adiabatic temperature rise of concrete mixtures based on isothermal calorimetry. It is proposed that performing isothermal calorimetry at different temperatures is sufficient to predict heat of hydration under adiabatic conditions with high accuracy. The method is validated through the simulation of the internal temperatures of two mid-scale experiments which involve different cementitious materials. The method is also used to calculate adiabatic temperature rise curves for nine different concrete mixtures with varying characteristics. Utilizing the robust isothermal calorimetry to find accurate adiabatic temperature rises is of technological value since it facilitates the optimization of mass concrete mixture selection.

Similar content being viewed by others

References

Gajda J, Vangeem M (2002) Controlling Temperatures in Mass Concrete. Concrete international 24:58-62

ACI (2007) ACI PRC-207.2–07 Report on Thermal and Volume Change Effects on Cracking of Mass Concrete. American Concrete Institute, Farmington Hills, MI

Gross E (2017) Development of a Mass Concrete Specification for Use in ALDOT Bridge Construction. Auburn University

Collepardi M (2003) A state-of-the-art review on delayed ettringite attack on concrete. Cement Concr Compos 25:401–407

ACI (2000) ACI 116R-90: Cement and Concrete Terminology. American Concrete Institute, Farmington Hills, MI

CSA (2019) CSA A23.1/A23.2 Concrete materials and methods of concrete construction /Test methods and standard practices for concrete. CSA group, Canada

ACI (2006) ACI 207.1R-05 Guide to Mass Concrete. American Concrete Institute, Farmington Hills, MI

Chini A, Acquaye L (2005) Effect of elevated curing temperatures on the strength and durability of concrete. Mater Struct 38:673–679

Escalante-Garcıa J, Sharp J (1998) Effect of temperature on the hydration of the main clinker phases in Portland cements: Part II, blended cements. Cem Concr Res 28:1259–1274

Schindler AK, Folliard KJ (2005) Heat of hydration models for cementitious materials. ACI Mater J 102:24

Poole J, Riding K, Folliard K et al (2007) Hydration study of cementitious materials using semi-adiabatic calorimetry. Spec Publ 241:59–76

Wadso L (2020) An overview of different types of calorimeters used to study cement hydration

Wadso L (2003) An experimental comparison between isothermal calorimetry, semi-adiabatic calorimetry and solution calorimetry for the study of cement hydration (NT TR 522). NORDTEST, Finland

Riding KA, Poole JL, Folliard KJ et al (2012) Modeling hydration of cementitious systems. ACI Mater J 109:225–234

Carino NJ (1984) The maturity method: theory and application. Cem Concr AggreG 6:61–73

ASTM International (2017) ASTM C1679 standard practice for measuring hydration kinetics of hydraulic cementitious mixtures using isothermal calorimetry. ASTM International, West Conshohocken, PA

Top LafargeHolcim mills sustain portland limestone cement momentum – Concrete Products. https://concreteproducts.com/index.php/2022/01/17/top-lafargeholcim-mills-sustain-portland-limestone-cement-momentum/. Accessed 25 Jan 2022

Xu Q, Wang K, Medina C, Engquist B (2015) A mathematical model to predict adiabatic temperatures from isothermal heat evolutions with validation for cementitious materials. Int J Heat Mass Transf 89:333–338

De Schutter G, Taerwe L (1996) Degree of hydration-based description of mechanical properties of early age concrete. Mater Struct 29:335–344

Byfors J (1980) Plain concrete at early ages. Swedish Cement and Concrete Research Institute, Stockholm

Freiesleben Hansen P, Pedersen E (1985) Curing of Concrete Structures. CEB Inf Bull 166

Knudsen T (1982) Modeling hydration of Portland cement—the effect of particle size distribution. In: Proceedings of the engineering foundation conference on characterization and performance prediction of cement and concrete. Henniker, NH

Schindler AK (2002) Concrete hydration, temperature development, and setting at early-ages. The University of Texas at Austin, US

Lin F, Meyer C (2009) Hydration kinetics modeling of Portland cement considering the effects of curing temperature and applied pressure. Cem Concr Res 39:255–265

Mills R (1966) Factors influencing cessation of hydration in water cured cement pastes. Highway Research Board Special Report 406-424

Riding KA, Vosahlik J, Bartojay K et al (2019) Methodology comparison for concrete adiabatic temperature rise. ACI Mat J 116:45–53

Bogue RH (1955) The chemistry of Portland cement. LWW

Huang L, Yan P (2019) Effect of alkali content in cement on its hydration kinetics and mechanical properties. Constr Build Mater 228:116833

Van Breugel K (1998) Prediction of temperature development in hardening concrete. Prev Therm Crack Concr Early Ages 15:51–75

Hawkins P, Tennis PD, Detwiler RJ (1996) The use of limestone in Portland cement: a state-of-the-art review. Portland Cement Association, Illinois

Maruyama I, Lura P (2019) Properties of early-age concrete relevant to cracking in massive concrete. Cem Concr Res 123:105770

Freiesleben Hansen P, Pedersen EJ (1977) Maturity computer for controlled curing and hardening of concrete. Nordisk Betong

Dolado JS, Van Breugel K (2011) Recent advances in modeling for cementitious materials. Cem Concr Res 41:711–726

Poole JL, Riding KA, Folliard KJ et al (2007) Methods for calculating activation energy for Portland cement. ACI Mater J 104:303–311

Zhang J, Cusson D, Monteiro P, Harvey J (2008) New perspectives on maturity method and approach for high performance concrete applications. Cem Concr Res 38:1438–1446

Thomas JJ (2012) The instantaneous apparent activation energy of cement hydration measured using a novel calorimetry-based method. J Am Ceram Soc 95:3291–3296

Riding KA, Poole JL, Folliard KJ, et al (2011) New Model for Estimating Apparent Activation Energy of Cementitious Systems. ACI Materials Journal 108:550-557

Broda M, Wirquin E, Duthoit B (2002) Conception of an isothermal calorimeter for concrete— Determination of the apparent activation energy. Mat Struct 35:389–394. https://doi.org/10.1007/BF02483141

Xu G, Tian Q, Miao J, Liu J (2017) Early-age hydration and mechanical properties of high volume slag and fly ash concrete at different curing temperatures. Constr Build Mater 149:367–377

Lerch W, Ford C (1948) Long-time study of cement performance in concrete. In: Journal Proceedings. pp 745–796

Neville A (2001) Consideration of durability of concrete structures: past, present, and future. Mater Struct 34:114–118. https://doi.org/10.1007/BF02481560

Riding K, Schindler AK, Pesek P, et al (2017) ConcreteWorks v3 training/user manual (P1) : ConcreteWorks software (P2)

Xu Q, Ruiz JM, Hu J et al (2011) Modeling hydration properties and temperature developments of early-age concrete pavement using calorimetry tests. Thermochim Acta 512:76–85

Powers TC (1968) The properties of fresh concrete. John Wiley & Sons, New York

Williams DA, Saak AW, Jennings HM (1999) The influence of mixing on the rheology of fresh cement paste. Cem Concr Res 29:1491–1496

Han D, Ferron RD (2016) Influence of high mixing intensity on rheology, hydration, and microstructure of fresh state cement paste. Cem Concr Res 84:95–106

Pang X, Cuello Jimenez W, Singh J (2020) Measuring and modeling cement hydration kinetics at variable temperature conditions. Constr Build Mater 262:120788. https://doi.org/10.1016/j.conbuildmat.2020.120788

Pang X, Sun L, Sun F et al (2021) Cement hydration kinetics study in the temperature range from 15 °C to 95 °C. Cem Concr Res 148:106552. https://doi.org/10.1016/j.cemconres.2021.106552

Emmanuel AC, Krishnan S, Bishnoi S (2022) Influence of curing temperature on hydration and microstructural development of ordinary Portland cement. Constr Build Mater 329:127070. https://doi.org/10.1016/j.conbuildmat.2022.127070

Breval E (1976) C3A hydration. Cem Concr Res 6:129–137

ASTM International (2020) ASTM C305–20 standard practice for mechanical mixing of hydraulic cement pastes and mortars of plastic consistency. ASTM International, PA

ASTM International (2019) ASTM C1738 / C1738M–19 standard practice for high-shear mixing of hydraulic cement pastes. ASTM International, PA

Van Breugel K (1980) Artificial cooling of hardening concrete. Delft University of Technology, Delft

Poppe A-M, De Schutter G (2005) Cement hydration in the presence of high filler contents. Cem Concr Res 35:2290–2299. https://doi.org/10.1016/j.cemconres.2005.03.008

Uchida K, Sakakibara H, Saito Y Sekisanhatsunetsuryo ni motozuku semento no suiwahatsunetsusokudo no teishikika to ondojyosyo no yosoku (Prediction of adiabatic temperature rise of concrete based on the formulation of the rate of cement hydration as a function of the cumulative heat liberation). Concrete Journal (JCI) 24:105–113

b4cast - Simulation of Hardening Concrete. http://www.b4cast.com/b4cast/b4cast.html. Accessed 1 Apr 14AD

Snelson DG, Wild S, O’Farrell M (2008) Heat of hydration of Portland Cement–Metakaolin–Fly ash (PC–MK–PFA) blends. Cem Concr Res 38:832–840

Fajun W, Grutzeck MW, Roy DM (1985) The retarding effects of fly ash upon the hydration of cement pastes: the first 24 h. Cem Concr Res 15:174–184

Sakai K, Watanabe H, Suzuki M, Hamazaki K (1992) Properties of granulated blast-furnace slag cement concrete. Special Publ 132:1367–1384

Hwang C-L, Shen D-H (1991) The effects of blast-furnace slag and fly ash on the hydration of Portland cement. Cem Concr Res 21:410–425

Vuk T, Tinta V, Gabrovšek R, Kaučič V (2001) The effects of limestone addition, clinker type and fineness on properties of Portland cement. Cem Concr Res 31:135–139

Acknowledgements

The authors would like to extend their appreciation and gratitude for the financial support provided by the Georgia Department of Transportation under the Research Projects No. 16-25 and No. 19-04. Any opinions, findings, and conclusions or recommendations expressed in this work are those of the author(s) and do not necessarily reflect the views of the Georgia Department of Transportation.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Al-Hasani, L.E., Park, J., Perez, G. et al. Quantifying concrete adiabatic temperature rise based on temperature-dependent isothermal calorimetry; modeling and validation. Mater Struct 55, 191 (2022). https://doi.org/10.1617/s11527-022-02023-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-022-02023-6