Abstract

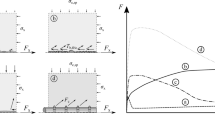

The repair of existing reinforced concrete elements is mainly realized by overlaying them with a higher strength concrete layer strengthened with reinforcement, known as jacketing. The efficiency of the method is based on the stress transfer and strain compatibility at the interface. The common methods used on-site to enhance the concrete-to-concrete bond is roughening the surface and/or applying a bonding agent layer on the old concrete surface. The purpose of this research is to evaluate the contribution of roughness and bonding agent on the bonding strength and, additionally, to develop a general predictive model. Thus, three different levels of roughness were materialized: (i) left-as-cast, (ii) wire-brushed and, (iii) splitting-fractured while two modes of adhesion were tested: (i) substrate with repair cement paste and, (ii) use of a bonding agent. Bi-surface symmetrical shear tests were carried out to assess the ultimate bonding strength of specimens with properties usually found in situ. The experimental results showed that an increase of roughness leads to a better bond performance. The bonding agent effect, however, was notable only for the left-as-cast specimens. A physically-based model is proposed to predict the shear bonding strength concerning the surface roughness, as well as the old and repair concrete’s properties. The model aims to offer to designers and researchers an accurate tool to evaluate the effectiveness of the interfacial bond in renovation jacketing procedures.

Similar content being viewed by others

Change history

29 June 2022

A Correction to this paper has been published: https://doi.org/10.1617/s11527-022-01999-5

References

Vainio TH (2011) Building renovation: a new industry? In: TU delft repository

Hasik V, Escott E, Bates R et al (2019) Comparative whole-building life cycle assessment of renovation and new construction. Build Environ. https://doi.org/10.1016/j.buildenv.2019.106218

Andrew RM (2019) Global CO2 emissions from cement production, 1928–2018. Earth Syst Sci Data 10(1):195–217

Tilly G, Jacobs J (2007) Concrete repairs: performance in service and current practice. IHS Bre Press, Bracknell

Júlio ES, Branco F, Silva VD (2003) Structural rehabilitation of columns with reinforced concrete jacketing. Prog Struct Eng Mater. https://doi.org/10.1002/pse.140

Tsioulou OT, Lampropoulos AP, Dritsos SE (2013) Experimental investigation of interface behaviour of RC beams strengthened with concrete layers. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2012.09.093

Thermou GE, Kappos AJ (2022) Background to the monolithicity factors for the assessment of jacketed reinforced concrete columns. Buildings. https://doi.org/10.3390/buildings12010055

Grand View Research (2021) Precast Concrete Market Size, Share and Trends Analysis Report By Product (Structural Building Components, Transportation Products), By End-use (Residential, Infrastructure), By Region, And Segment Forecasts. 2021–2028

Tajul AS, Yunus R, Mohammad H, Yaman SK (2017) A preliminary review on economies of scale (EOS) towards industrialized building system (IBS) manufacturer. In: MATEC Web of Conferences. EDP Sciences Publishing: France. p 03008

Murari SS, Joshi AM (2019) Precast Construction Methodology in Construction Industry. SSRN Electron J. https://doi.org/10.2139/ssrn.3496019

Santos DS, Santos PMD, Dias-da-Costa D (2012) Effect of surface preparation and bonding agent on the concrete-to-concrete interface strength. Constr Build Mater 37:102–110. https://doi.org/10.1016/j.conbuildmat.2012.07.028

He Y, Zhang X, Hooton RD, Zhang X (2017) Effects of interface roughness and interface adhesion on new-to-old concrete bonding. Constr Build Mater 151:582–590. https://doi.org/10.1016/j.conbuildmat.2017.05.049

Ulio ENBSJ, Branco FAB, Silva D (2004) Concrete-to-concrete bond strength. Influence of the roughness of the substrate surface. Build Environ. https://doi.org/10.1016/j.conbuildmat.2004.04.023

Beushausen H, Höhlig B, Talotti M (2017) The influence of substrate moisture preparation on bond strength of concrete overlays and the microstructure of the OTZ. Cem Concr Res 92:84–91. https://doi.org/10.1016/j.cemconres.2016.11.017

Courard L (2005) Adhesion of repair systems to concrete: Influence of interfacial topography and transport phenomena. Mag Concr Res. https://doi.org/10.1680/macr.2005.57.5.273

Valikhani A, Jahromi AJ, Mantawy IM, Azizinamini A (2020) Experimental evaluation of concrete-to-UHPC bond strength with correlation to surface roughness for repair application. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2019.117753

Zhang Y, Zhu P, Liao Z, Wang L (2020) Interfacial bond properties between normal strength concrete substrate and ultra-high performance concrete as a repair material. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2019.117431

Farzad M, Shafieifar M, Azizinamini A (2019) Experimental and numerical study on bond strength between conventional concrete and ultra high-performance concrete (UHPC). Eng Struct. https://doi.org/10.1016/j.engstruct.2019.02.030

Tayeh BA, Abu Bakar BH, Johari MAM (2012) Characterization of the interfacial bond between old concrete substrate and ultra high performance fiber concrete repair composite. Mater Struct. https://doi.org/10.1617/s11527-012-9931-1

Ganesh P, Ramachandra Murthy A (2020) Simulation of surface preparations to predict the bond behaviour between normal strength concrete and ultra-high performance concrete. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2020.118871

EN 1504 (2004) Products and systems for the protection and repair of concrete structures. In: Definitions, requirements, quality control and evaluation of conformity surface protection systems for concrete. Thomas Telford Publishing: London. pp 361–370

Luc T, Matthys S (2013) Fib model code for concrete structures 2010. Wiley, New Jerssy

Santos PMD, Júlio ENBS (2012) A state-of-the-art review on shear-friction. Eng Struct 45:435–448

Courard L, Piotrowski T, Garbacz A (2014) Near-to-surface properties affecting bond strength in concrete repair. Cement Concr Compos 46:73–80. https://doi.org/10.1016/j.cemconcomp.2013.11.005

Martín-Pérez B, Pantazopoulou SJ (2001) Effect of bond, aggregate interlock and dowel action on the shear strength degradation of reinforced concrete. Eng Struct 23:214–227

Thermou GE, Pantazopoulou SJ, Elnashai AS (2004) Analytical modeling of interface behavior in reinforced concrete jacketed members. In: proceedings of the 2004 structures congress-building on the past securing the future. pp 389–396

Austin S, Robins P, Pan Y (1999) Shear bond testing of concrete repairs. Cem Concr Res. https://doi.org/10.1016/S0008-8846(99)00088-5

Santos PMD, Julio ENBS (2011) Factors affecting bond between new and old concrete. ACI Mater J. https://doi.org/10.14359/51683118

Júlio ENBS, Branco FAB, Silva VD, Lourenço JF (2006) Influence of added concrete compressive strength on adhesion to an existing concrete substrate. Build Environ 41:1934–1939. https://doi.org/10.1016/J.BUILDENV.2005.06.023

Eurocode 2 (2004) Design of concrete structures–part 1–1: general rules and rules for buildings. The European union per regulation 305/2011, directive 98/34/EC, directive 2004/18/ECJ

Alvarez R, Veiga S, Martínez-Ramírez M, Secco P, Faria PN, Maravelaki M, Ramesh I, Papayianni J, Válek JI (2021) RILEM TC 277-LHS report: a review on the mechanisms of setting and hardening of lime-based binding systems. Mater Struct. https://doi.org/10.1617/s11527-021-01648-3

Momayez A, Ehsani MR, Ramezanianpour AA, Rajaie H (2005) Comparison of methods for evaluating bond strength between concrete substrate and repair materials. Cem Concr Res. https://doi.org/10.1016/j.cemconres.2004.05.027

Courard L (2000) Parametric study for the creation of the interface between concrete and repair products. Mater Struct Mater et Constr. https://doi.org/10.1007/bf02481698

Lukovic M, Savija B, Dong H et al (2014) Micromechanical Study of the Interface Properties in Concrete Repair Systems. J Adv Concr Technol 12:320–339

Xie HC, Li GY, Xiong GJ (2002) Microstructure model of the interfacial zone between fresh and old concrete. J Wuhan Univ Technol Mater Sci Ed. https://doi.org/10.1007/bf02838421

Courard L, Piotrowski T, Garbacz A (2013) Near-to-surface properties affecting bond strength in concrete repair. Cem Concr Compos. https://doi.org/10.1016/j.cemconcomp.2013.11.005

Yazdi MA, Dejager E, Gruyaert E et al (2019) Bond strength between concrete and repair mortar and its relation with concrete removal techniques and substrate composition. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2019.116900

Omar B, Boumediene H, Kharchi F (2010) Influence of the roughness and moisture of the substrate surface on the bond between old and new concrete. Contemp Eng Sci 3:139–147

Chorinsky G, Erhard D (1986) Repair of concrete floors with polymer modified cement mortars. In: Sasse HR (ed) Adhesion between polymers and concrete/Adhésion entre polymères et béton. Springer, Boston, MA

Bentz DP, de la Varga I, Muñoz JF et al (2018) Influence of substrate moisture state and roughness on interface microstructure and bond strength: Slant shear vs. pull-off testing. Cem Concr Compos 87:63–72. https://doi.org/10.1016/j.cemconcomp.2017.12.005

Emmons PH (1996) Concrete repair and maintenance illustrated: problem analysis, repair strategy, and techniques, RSmeans. Wiley, New Jerssy

Andrea S, Vittorio M (1999) Durability of epoxy resin-based materials for the repair of damaged cementitious composites. Cem Concr Res 29:95–98

Guo SY, Zhang X, Chen JZ et al (2020) Mechanical and interface bonding properties of epoxy resin reinforced Portland cement repairing mortar. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2020.120715

Cleland DJ, Long AE (1997) The pull-off test for concrete patch repairs. Proc Inst Civ Eng Struct Build. https://doi.org/10.1680/istbu.1997.29833

Austin S, Robins P, Pan Y (1995) Tensile bond testing of concrete repairs. Mater Struct. https://doi.org/10.1007/BF02473259

Silfwerbrand J, Paulsson J (1998) Better bonding of bridge deck overlays. Concr Int 20:56–61

Silfwerbrand J, Beushausen H, Courard L (2011) Bonded cement-based material overlays for the repair, the lining or the strengthening of slabs or pavements. Springer, New York

Júlio ENBS, Branco FAB, Silva VD (2005) Concrete-to-concrete bond strength: Influence of an epoxy-based bonding agent on a roughened substrate surface. Mag Concr Res. https://doi.org/10.1680/macr.2005.57.8.463

Garbacz A, Górka M, Courard L (2005) Effect of concrete surface treatment on adhesion in repair systems. Mag Concr Res. https://doi.org/10.1680/macr.2005.57.1.49

Raoof SM, Koutas LN, Bournas DA (2016) Bond between textile-reinforced mortar (TRM) and concrete substrates: experimental investigation. Compos B Eng. https://doi.org/10.1016/j.compositesb.2016.05.041

Koutas LN, Tetta Z, Bournas DA, Triantafillou TC (2019) Strengthening of Concrete Structures with Textile Reinforced Mortars: State-of-the-Art Review. J Compos Constr. https://doi.org/10.1061/(asce)cc.1943-5614.0000882

Pohoryles DA, Melo J, Rossetto T (2021) Combined flexural and shear strengthening of rc t-beams with frp and trm: experimental study and parametric finite element analyses. Buildings. https://doi.org/10.3390/buildings11110520

EN 206-1 (2000) Performance-based specifications and control of concrete durability concrete part 1, specification, performance, production and conformity

Tsonos AD, Kalogeropoulos G, Iakovidis P et al (2021) Seismic performance of rc beam–column joints designed according to older and modern codes: an attempt to reduce conventional reinforcement using steel fiber reinforced concrete. Fibers. https://doi.org/10.3390/fib9070045

Ambroziak A, Haustein E (2022) Properties of old concrete built in the former Leipziger palace. Mater MDPI 15:673

Ambroziak A, Haustein E, Kondrat J (2019) Chemical and Mechanical Properties of 70-Year-Old Concrete. J Mater Civ Eng. https://doi.org/10.1061/(asce)mt.1943-5533.0002840

British Standard Institution (2009) Testing fresh concrete — part 2: slump test. BS EN 12350–2

ASTM-C469 (2002) ASTM C469-02: Standard test method for static modulus of elasticity and poisson’s ratio of concrete in compression. ASTM Standard Book. 4: 469

JCI-S-001-2003 (2003) Method of test for fracture energy of concrete by use of notched beam. Japan Concrete Institute

ASTM C293-02 (2002) Standard test method for flexural strength of concrete (using simple beam with center-point loading). ASTM international, West Conshohocken, PA. www.astm.org

Santos PMD, Júlio ENBS (2013) A state-of-the-art review on roughness quantification methods for concrete surfaces. Constr Build Mater 38:912–923. https://doi.org/10.1016/J.CONBUILDMAT.2012.09.045

Garbacz A, Courard L, Kostana K (2006) Characterization of concrete surface roughness and its relation to adhesion in repair systems. Mater Charact. https://doi.org/10.1016/j.matchar.2005.10.014

EN 1766 (2000) Products and systems for the protection and repair of concrete structures-test methods-reference concretes for testing

Rashid K, Ahmad M, Ueda T et al (2020) Experimental investigation of the bond strength between new to old concrete using different adhesive layers. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2020.118798

Silfwerbrand J (2003) Shear bond strength in repaired concrete structures. Mater Struct. https://doi.org/10.1007/bf02481068

Thermou GE, Papanikolaou VK, Kappos AJ (2011) Analytical model for predicting the response of oldtype columns rehabilitated with concrete jacketing under reversed cyclic loading. In: ECCOMAS thematic conference-COMPDYN 2011: 3rd international conference on computational methods in structural dynamics and earthquake engineering: an IACM special interest conference

Birkeland PW (1966) Connections in precast concrete construction. ACI J Proc https://doi.org/10.14359/7627

MATLAB (2019) version 9.7.0 9 (R2019b). The MathWorks Inc

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original online version of this article was revised: The original article was inadvertedly published containing a mistake in Equation 4. The name of the second author should read Kyriaki S. Galopoulo.

Rights and permissions

About this article

Cite this article

Apostolinas, V.G., Galopoulou, K.S., Kouris, L.A.S. et al. Experimental investigation and analytical modelling of the roughness and bonding agent influence on the old-to-repair concrete interfacial bonding strength. Mater Struct 55, 148 (2022). https://doi.org/10.1617/s11527-022-01984-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-022-01984-y