Abstract

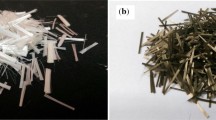

This paper presents the results of experimental investigations on the permeability of basalt fibre engineered cementitious composite (BF-ECC) in terms of water absorption and chloride resistance. Cylindrical specimens with five fibre volume fractions (0.0, 0.5, 1.0, 1.5 and 2.0%) were prepared and cured for 28 or 56 days. The water absorption, charge passed, chloride diffusion coefficient, microstructure and pore structure were determined. Macro-test results showed that BF could enhance the ability of ECC to resist water and chloride ions penetration, and this positive effect was weakened as fibre volume climbed. Microstructure indicated that the presence of BF restricted the progradation of microcracks in the matrix, nonetheless, the debonding and entangling of fibres at fibre fractions of 1.5% and 2.0% were captured, accompanied by visible cracks and voids. Also, the addition of BF decreased the number of pores in the range of 10 nm to 100 nm, and the most critical pore was decreased. Incorporating 1.0% BF decreased the porosity of ECC, while the addition of 2.0% BF increased. Herein the paper, BF-ECC with a 1.0% fibre volume fraction is preferred.

Similar content being viewed by others

References

Li VC (2019) Engineered cementitious composites (ECC): bendable concrete for sustainable and resilient infrastructure. Springer, Berlin

Sahmaran M, Li VC (2009) Durability properties of micro-cracked ECC containing high volumes fly ash. Cem Concr Res 39(11):1033–1043. https://doi.org/10.1016/j.cemconres.2009.07.009

Sahmaran M, Lachemi M, Hossain KMA, Li VC (2009) Internal curing of engineered cementitious composites for prevention of early age autogenous shrinkage cracking. Cem Concr Res 39(10):893–901. https://doi.org/10.1016/j.cemconres.2009.07.006

Sahmaran M, Li VC (2010) Engineered cementitious composites: Can composites be accepted as crack-free concrete? Transportation Research Record. J Transp Res Board 2164(1):1–8. https://doi.org/10.3141/2164-01

Yu KQ, Dai JG, Lu ZD, Leung CKY (2015) Mechanical properties of engineered cementitious composites subjected to elevated temperatures. J Mater Civ Eng 27(10):04014268. https://doi.org/10.3141/2164-01

Yu J, Lin J, Zhang Z, Li VC (2015) Mechanical performance of ECC with high-volume fly ash after sub-elevated temperatures. Constr Build Mater 99:82–89. https://doi.org/10.1016/j.conbuildmat.2015.09.002

Wang Q, Yi Y, Ma G, Luo H (2019) Hybrid effects of steel fibres, basalt fibres and calcium sulfate on mechanical performance of PVA-ECC containing high-volume fly ash. Cem Concr Compos 97:357–368. https://doi.org/10.1016/j.cemconcomp.2019.01.009

Ramakrishnan V, Tolmare NS, Brik VB (1998) Performance evaluation of 3-D basalt fibre reinforced concrete & basalt rod reinforced concrete. Transportation Research Board, Washington, USA, pp 34–36.

Jiang C, Fan K, Wu F, Chen D (2014) Experimental study on the mechanical properties and microstructure of chopped basalt fibre reinforced concrete. Mater Des 58:187–193. https://doi.org/10.1016/j.matdes.2014.01.056

Branston J, Das S, Kenno SY, Taylor C (2016) Mechanical behaviour of basalt fibre reinforced concrete. Constr Build Mater 124:878–886. https://doi.org/10.1016/j.conbuildmat.2016.08.009

Xu M, Song S, Feng L, Zhou J, Li H, Li VC (2021) Development of basalt fibre engineered cementitious composites and its mechanical properties. Constr Build Mater 266:121173. https://doi.org/10.1016/j.conbuildmat.2020.121173

Wu Z, Wong HS, Buenfeld NR (2017) Transport properties of concrete after drying-wetting regimes to elucidate the effects of moisture content, hysteresis and microcracking. Cem Concr Res 98:136–154. https://doi.org/10.1016/j.cemconres.2017.04.006

Miyazato S, Hiraishi Y (2005). Transport properties and steel corrosion in ductile fibre reinforced cement composites. In Proceedings of the Eleventh International Conference on Fracture, Turin, Italy, pp 20–25

Sahmaran M, Li VC (2009) Influence of microcracking on water absorption and sorptivity of ECC. Mater Struct 42(5):593–603. https://doi.org/10.1617/s11527-008-9406-6

Algin Z, Ozen M (2018) The properties of chopped basalt fibre reinforced self-compacting concrete. Constr Build Mater 186:678–685. https://doi.org/10.1016/j.conbuildmat.2018.07.089

Sadrmomtazi A, Tahmouresi B, Saradar A (2018) Effects of silica fume on mechanical strength and microstructure of basalt fiber reinforced cementitious composites (BFRCC). Constr Build Mater 162:321–333. https://doi.org/10.1016/j.conbuildmat.2017.11.159

Standard Test Method for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration, ASTM Standard C1202–12

Lu XY, Zhang HX, Wang RX (2003) Comment on permeability measurement of concrete. Concr Cem Prod 4:7–9 (in Chinese)

Wang L, He TS, Zhou YX, Tang SW, Tan JJ, Liu ZT, Su JW (2021) The influence of fiber type and length on the cracking resistance, durability and pore structure of face slab concrete. Constr Build Mater 282:122706. https://doi.org/10.1016/j.conbuildmat.2021.122706

Hall C, Hoff WD, Taylor SC, Wilson MA, Yoon BG, Reinhardt HW, Donald AM (1995) Water anomaly in capillary liquid absorption by cement-based materials. J Mater Sci Lett 14(17):1178–1181. https://doi.org/10.1007/bf00291799

Zhou C, Ren F, Wang Z, ChenW WW (2017) Why permeability to water is anomalously lower than that to many other fluids for cement-based material? Cem Concr Res 100:373–384. https://doi.org/10.1016/j.cemconres.2017.08.002

Zhang LF, Wang DF (2018) Effect of basalt fiber content on sulfate resistance and impermeability of concrete. Bull Chin Ceram Soc 37:1946–1950

He R, Ma H, Hafiz RB, Fu C, Jin X, He J (2018) Determining porosity and pore network connectivity of cement-based materials by a modified non-contact electrical resistivity measurement: Experiment and theory. Mater Des 156:82–92. https://doi.org/10.1016/j.matdes.2018.06.045

He R, Ye H, Ma H, Fu C, Jin X, Li Z (2019) Correlating the chloride diffusion coefficient and pore structure of cement-based materials using modified noncontact electrical resistivity measurement. J Mater Civ Eng 31(3):04019006. https://doi.org/10.1061/(ASCE)MT.1943-5533.0002616

Wu Z, Wong HS, Chen C, Buenfeld NR (2019) Anomalous water absorption in cement-based materials caused by drying shrinkage induced microcracks. Cem Concr Res 115:90–104. https://doi.org/10.1016/j.cemconres.2018.10.006

Acknowledgements

The author would like to thank the Building Materials Laboratory of Harbin Engineering University for their help.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There are no conflicts of interest for this work.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hu, X., Xia, K. Experimental study on the permeability of basalt fibre engineered cementitious composite (ECC). Mater Struct 55, 85 (2022). https://doi.org/10.1617/s11527-022-01925-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-022-01925-9