Abstract

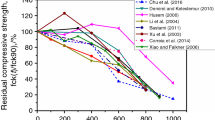

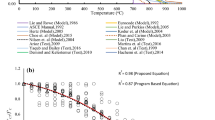

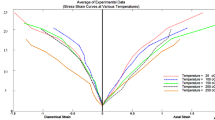

In a fire incident, structural members are mostly unevenly exposed to temperatures and consequently suffer uneven damage. To rehabilitate and restore these for future usage, it is essential to correctly map the temperature field that the structural elements were subjected to during fire events. The majority of the existing relationships for temperature prediction apply to reinforced concrete beams only. In the present study, a material-porosity-based approach is proposed. Normal and high strength concrete structural elements were exposed to a range of elevated temperatures, and reserved compressive strength was evaluated. Another set of the same specimens were used to determine porosity using four techniques. Based on the observations, correlations among temperature, strength, and porosity for normal and high strength concrete are proposed. The suggested methodology and expressions may be used to predict the reserved strength and temperature field that the structural elements may have been exposed to, based on the evaluated porosity of concrete. Back-scattered electron Imaging was found to be the most fitting method for porosity evaluation.

Similar content being viewed by others

Data availability

All data, models, and code generated or used during the study appear in the submitted article.

Abbreviations

- \({\sigma }_{T}\) :

-

Reserved compressive strength of concrete for any temperature T

- \({\sigma }_{RT}\) :

-

Reserved compressive strength of concrete at room temperature T

- \({P}_{T,NSC}\) :

-

Porosity of NSC at any temperature T

- \({P}_{T,HSC}\) :

-

Porosity of HSC at any temperature T

References

Wickstrom U (1986) Very simple method for estimating temperature in fire exposed concrete structures. In: RISE, SP- Sveries Tekniska Forskning Institut, SP Fire Research

ISO (1999) Elements of building construction - Part 1: general requirements. Fire-resistance tests

Desai SB (1998) Design of reinforced concrete beams under fire exposure conditions. Mag Concr Res 50:75–83. https://doi.org/10.1680/macr.1998.50.1.75

Abbasi A, Hogg PJ (2005) A model for predicting the properties of the constituents of a glass fibre rebar reinforced concrete beam at elevated temperatures simulating a fire test. Compos B Eng 36:384–393. https://doi.org/10.1016/j.compositesb.2005.01.005

Kodur VKR, Yu B, Dwaikat MMS (2013) A simplified approach for predicting temperature in reinforced concrete members exposed to standard fire. Fire Saf J 56:39–51. https://doi.org/10.1016/j.firesaf.2012.12.004

Kodur VKR, Yu B, Solhmirzaei R (2017) A simplified approach for predicting temperatures in insulated RC members exposed to standard fire. Fire Saf J 92:80–90. https://doi.org/10.1016/j.firesaf.2017.05.018

Gao WY, Dai JG, Teng JG (2014) Simple method for predicting temperatures in reinforced concrete beams exposed to a standard fire. Adv Struct Eng 17:573–589. https://doi.org/10.1260/1369-4332.17.4.573

Abdel Aziz YH, Abdel Zaher Y, Wahab MA, Khalaf M (2019) Predicting temperature rise in Jacketed concrete beams subjected to elevated temperatures. Constr Build Mater 227:116460. https://doi.org/10.1016/j.conbuildmat.2019.07.186

Kang H, Cho H-C, Choi S-H et al (2019) Estimation of heating temperature for fire-damaged concrete structures using adaptive neuro-fuzzy inference system. Materials. https://doi.org/10.3390/MA12233964

Cho HC, Han SJ, Heo I et al (2020) Heating temperature prediction of concrete structure damaged by fire using a bayesian approach. Sustainability. https://doi.org/10.3390/SU12104225

Ryshkewitch E (1953) Compression strength of porous sintered alumina and zirconia. J Am Cer Soci 36:65–68. https://doi.org/10.1111/j.1151-2916.1953.tb12837.x

Chan SYN, Peng G, Chan JKW (1996) Comparison between high strength concrete and normal strength concrete subjected to high temperature. Mater Struct 29:616–619. https://doi.org/10.1007/BF02485969

Vodák F, Trtík K, Kapičková O et al (2004) The effect of temperature on strength - Porosity relationship for concrete. Constr Build Mater 18:529–534. https://doi.org/10.1016/j.conbuildmat.2004.04.009

Bažant ZP, Jirásek M (2018) Creep and hygrothermal effects in concrete structures

Xue S, Zhang P, Bao J et al (2020) Comparison of Mercury Intrusion Porosimetry and multi-scale X-ray CT on characterizing the microstructure of heat-treated cement mortar. Mater Charact. https://doi.org/10.1016/j.matchar.2019.110085

Chan YN, Luo X, Sun W (2000) Compressive strength and pore structure of high-performance concrete after exposure to high temperature up to 800°C. Cem Concr Res 30:247–251. https://doi.org/10.1016/S0008-8846(99)00240-9

Peng GF, Huang ZS (2008) Change in microstructure of hardened cement paste subjected to elevated temperatures. Constr Build Mater 22:593–599. https://doi.org/10.1016/j.conbuildmat.2006.11.002

Cong X, Kirkpatrick RJ (1995) Effects of the temperature and relative humidity on the structure of CSH gel. Cem Concr Res 25:1237–1245. https://doi.org/10.1016/0008-8846(95)00116-T

Taylor HFW (1997) Cement chemistry. 2nd ed. Thomas Telford Publishing, London, p 361. https://doi.org/10.1680/cc.25929

Menéndez E, Vega L, Andrade C (2012) Use of decomposition of portlandite in concrete fire as indicator of temperature progression into the material: application to fire-affected builds. J Therm Anal Calorim 110:203–209. https://doi.org/10.1007/s10973-011-2159-4

Gallucci E, Zhang X, Scrivener KL (2013) Effect of temperature on the microstructure of calcium silicate hydrate (C-S-H). Cem Concr Res 53:185–195. https://doi.org/10.1016/j.cemconres.2013.06.008

Johnson WH, Parsons WH (1944) Thermal expansion of concrete aggregate materials. J Res National Bureau Stand, 32, March 1944. https://doi.org/10.6028/jres.032.002

Alonso C, Fernandez L (2004) Dehydration and rehydration processes of cement paste exposed to high temperature environments. J Mater Sci 39:3015–3024. https://doi.org/10.1023/B:JMSC.0000025827.65956.18

Shen J, Xu Q (2019) Effect of elevated temperatures on compressive strength of concrete. Constr Build Mater 229:116846

Kumar R, Bhattacharjee B (2003) Study on some factors affecting the results in the use of MIP method in concrete research. Cem Concr Res 33:417–424. https://doi.org/10.1016/S0008-8846(02)00974-2

Winslow D, Liu D (1990) The pore structure of paste in concrete. Cem Concr Res 20:227–235. https://doi.org/10.1016/0008-8846(90)90075-9

Mehta PK, Monteiro PJM (2006) Concrete: microstructure, properties, and materials. 3 rd ed. McGraw-Hill, New York, ISBN 071462899

Zhang B, He P, Poon CS (2020) Improving the high temperature mechanical properties of alkali activated cement (AAC) mortars using recycled glass as aggregates. Cement Concr Compos. https://doi.org/10.1016/j.cemconcomp.2020.103654

Liu Y, Zhuge Y, Chow CWK et al (2022) Effect of alum sludge ash on the high-temperature resistance of mortar. Resour Conserv Recycl. https://doi.org/10.1016/j.resconrec.2021.105958

Chen F, Li CQ, Baji H, Ma B (2018) Quantification of steel-concrete interface in reinforced concrete using backscattered electron imaging technique. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2018.05.246

Edwin RS, Mushthofa M, Gruyaert E, de Belie N (2019) Quantitative analysis on porosity of reactive powder concrete based on automated analysis of back-scattered-electron images. Cement Concr Compos. https://doi.org/10.1016/j.cemconcomp.2018.10.019

Liu Y, Chen SJ, Sagoe-Crentsil K, Duan W (2021) Digital concrete modelling: an alternative approach to microstructural pore analysis of cement hydrates. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2021.124558

Tchekwagep JJK, Chen D, Mukhopadhyay AK et al (2021) Quantitative Rietveld analysis of the decomposition of hardened rapid sulphoaluminate cement after exposure to elevated temperatures. Arch Civil Mech Eng. https://doi.org/10.1007/s43452-021-00265-9

IS 383 (2016) Coarse and fine aggregate for concrete - Specification. Bureau of Indian Satandards 1–18

American society of testing materials (2013) ASTM C494 standard specification for chemical admixtures for concrete. Annual book of ASTM Standards

BIS (1999) Specification for concrete admixtures. Bureau of Indian Standards

IS 3812 (Part-1) (2013) Pulverised fuel ash — Specification. Bureau of Indian Satandards

ASTM C618 (2012) Standard specification for coal fly ash and raw or calcined natural pozzolan for use. ASTM international, https://doi.org/10.1520/C0618

BIS (1988) Methods of physical tests for hydraulic cement, Part 11: Determination of density. Bureau of Indian Standards 4031 Part 11 2–6

BIS (1999) Methods of physical tests for hydraulic cement- determination of consistency of fineness by blaine air permeability method. IS 4031 Part-II

BIS (1985) Method of chemical analysis of hydraulic cement. 1–47

IS-516 (1959) Method of tests for strength of concrete. Indian Standard

Lawrence M, Jiang Y (2017) Porosity, pore size distribution, micro-structure. In: RILEM State-of-the-Art Reports

Wong HS, Head MK, Buenfeld NR (2006) Pore segmentation of cement-based materials from backscattered electron images. Cem Concr Res 36:1083–1090. https://doi.org/10.1016/j.cemconres.2005.10.006

Montes F, Valavala S, Haselbach LM (2005) A new test method for porosity measurements of portland cement pervious concrete. J ASTM Int 2:1–13. https://doi.org/10.1520/jai12931

Candaele RM, Barrett ME, Charbeneau RJ (2008) Porous friction course: A laboratory evaluation of hydraulic properties

Manahiloh KN, Muhunthan B, Kayhanian M, Gebremariam SY (2012) X-ray computed tomography and nondestructive evaluation of clogging in porous concrete field samples. J Mater Civ Eng. https://doi.org/10.1061/(asce)mt.1943-5533.0000484

BS EN 1992–1–2 (2004) Eurocode 2 Design of concrete structures - Part 1–2: General rules-Structural fire design. Design of concrete structures - Part 1–2: General rules-Structural fire design

Howell PGT, Davy KMW, Boyde A (1998) Mean atomic number and backscattered electron coefficient calculations for some materials with low mean atomic number. J Scann Microsco 20:35–40

ACI Committee 216 (1994) ACI 216R–90 Guide for determining the fire endurance of concrete elements. Concr Int, 3:13–47

Malik M, Bhattacharyya SK, Barai SV (2020) Thermal and mechanical properties of concrete and its constituents at elevated temperatures: a review. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2020.121398

Naus D (2005) The effect of elevated temperature on concrete materials and structures — a literature review. Contract 6283:184. https://doi.org/10.6088/ijcser.00202010079

Khoury GA (2002) Effect of fire on concrete and concrete structures. Prog Struct Mat Eng 2:429–447. https://doi.org/10.1002/pse.51

Malik M, Bhattacharyya SK, Barai S, v. (2021) Microstructural Changes in Concrete: Postfire Scenario. J Mater Civ Eng. https://doi.org/10.1061/(asce)mt.1943-5533.0003449

Zhang W, Sun Q, Hao S et al (2016) Experimental study on the variation of physical and mechanical properties of rock after high temperature treatment. Appl Therm Eng 98:1297–1304. https://doi.org/10.1016/j.applthermaleng.2016.01.010

Cnudde V, Cwirzen A, Masschaele B, Jacobs PJS (2009) Porosity and microstructure characterization of building stones and concretes. Eng Geol 103:76–83. https://doi.org/10.1016/j.enggeo.2008.06.014

Kjellsen KO, Detwiler RJ, Gjørv OE (1991) Development of microstructures in plain cement pastes hydrated at different temperatures. Cem Concr Res 21:179–189. https://doi.org/10.1016/0008-8846(91)90044-I

Noumowé A, Ranc G, Hochet C (2003) Moisture migration and thermo-mechanical behaviour of Concrete at up to 310 °C. In: Transactions of the 17th International conference on structural mechanics in reactor technology (SMiRT 17)

Zhang Y, Yang B, Yang Z, Ye G (2019) Ink-bottle effect and pore size distribution of cementitious materials identified by pressurization-depressurization cycling mercury intrusion porosimetry. Materials. https://doi.org/10.3390/ma12091454

Zhou J, Ye G, van Breugel K (2010) Characterization of pore structure in cement-based materials using pressurization-depressurization cycling mercury intrusion porosimetry (PDC-MIP). Cem Concr Res 40:1120–1128. https://doi.org/10.1016/j.cemconres.2010.02.011

Noumowe A (2005) Mechanical properties and microstructure of high strength concrete containing polypropylene fibres exposed to temperatures up to 200 °C. Cem Concr Res 35:2192–2198. https://doi.org/10.1016/j.cemconres.2005.03.007

Wang XS, Wu BS, Wang QY (2005) Online SEM investigation of microcrack characteristics of concretes at various temperatures. Cem Concr Res 35:1385–1390. https://doi.org/10.1016/j.cemconres.2004.07.015

Acknowledgements

The support of Structural Engineering Laboratory of Civil Engineering Department and Scanning Electron Microscope & X-Ray Diffraction Laboratories of Department of Geology and Geophysics is gratefully acknowledged.

Funding

No funds, grants, or other support was received.

The present research does not involve human participants or animals.

Author information

Authors and Affiliations

Contributions

All authors whose names appear on the submission. Made substantial contributions to the conception or design of the work; or the acquisition, analysis, or interpretation of data; or the creation of new software used in the work; Drafted the work or revised it critically for important intellectual content; Approved the version to be published; Agree to be accountable for all aspects of the work in ensuring that questions related to the accuracy or integrity of any part of the work are appropriately investigated and my resolved.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Malik, M., Bhattacharyya, S.K. & Barai, S.V. Temperature, porosity and strength relationship for fire affected concrete. Mater Struct 55, 72 (2022). https://doi.org/10.1617/s11527-022-01898-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-022-01898-9