Abstract

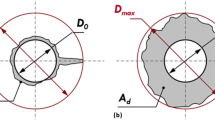

Composites of textile structure embedded in concrete matrix have a complex mechanical behaviour because it depends mainly on the bonds between the textile and the matrix. Those bonds cannot be controlled because they are determined by the impregnation degree of the yarn by the matrix, which is highly irregular in the cross section but also along the yarn. To quantify the impregnation degree of the yarn, a new visualization method was set up, using a double resin impregnation technique followed by confocal microscopy observations. Pull-out tests were performed on several samples with different matrices and different embedded lengths, before resin impregnation and observation. The physical parameters of the impregnation of the yarn were then linked to the pull-out mechanical parameters. The results show that the maximum load is directly linked to the number of filaments that are fully impregnated by the matrix, and this number depends on the composition of the matrix. The length and the shape of the filaments bundle pulled out without failing during the test were also determined and linked to the mechanical behaviour of the composite.

Similar content being viewed by others

References

Papanicolaou CG (2016) applications of textile-reinforced concrete in the precast industry. In: Triantafillou T (ed) Textile fibre composites in civil engineering. Woodhead Publishing, Sawston, pp 227–244. https://doi.org/10.1016/B978-1-78242446-8.00011-2

Kouris LAS, Triantafillou TC (2018) State-of-the-art on strengthening of masonry structures with textile reinforced mortar (TRM). Construct Build Mater 188:1221–1233. https://doi.org/10.1016/j.conbuildmat.2018.08.039

Wang X, Lam CC, Iu VP (2019) Comparison of different types of TRM composites for strengthening masonry panels. Construct Build Mater 219:184–194. https://doi.org/10.1016/j.conbuildmat.2019.05.179

Mechtcherine V (2013) Novel cement-based composites for the strengthening and repair of concrete structures. Construct Build Mater 41:365–373. https://doi.org/10.1016/j.conbuildmat.2012.11.117

Xu S, Li H (2007) Bond properties and experimental methods of textile reinforced concrete. J Wuhan Univ Technol Mater Sci Ed 22(3):529–532. https://doi.org/10.1007/s11595-006-3529-9

Häußler-Combe U, Hartig J (2007) Bond and failure mechanisms of textile reinforced concrete (TRC) under uniaxial tensile loading. Cem Concr Compos 29(4):279–289. https://doi.org/10.1016/j.cemconcomp.2006.12.012

Lepenies, I.: On the hierarchical material modelling of textile reinforced concrete. In: ICTRC’2006—1st International RILEM conference on textile reinforced concrete. RILEM Publications SARL, pp 223–232. https://doi.org/10.1617/2351580087.022

Zastrau B, Lepenies I, Richter M (2008) On the multi scale modeling of textile reinforced concrete. Tech Mech Eur J Eng Mech 28(1):53–63

Häußler-Combe U, Jesse F, Curbach M (2004) Textile reinforced concrete-overview, experimental and theoretical investigations. In: Fracture mechanics of concrete structures. Proceedings of the fifth international conference on fracture mechanics of concrete and concrete structures, Ia-FraMCos, Vail, CO, USA, vol 204, pp 12–16

Chudoba, R., Konrad, M., Mombartz, M., Vorechovsk, M., Meskouris, K.: Multiscale modeling of textile reinforced concrete within a consistent modeling framework

Hegger J, Sherif A, Bruckermann O, Konrad M (2004) Textile reinforced concrete: Investigations at different levels. Spec Publ 224:33–44. https://doi.org/10.14359/13406

Chudoba R, Voechovsk M, Konrad M (2006) Stochastic modeling of multi-filament yarns. I. Random properties within the cross-section and size effect. Int J Solids Struct 43(3):413–434. https://doi.org/10.1016/j.ijsolstr.2005.06.063

Voechovsk M, Chudoba R (2006) Stochastic modeling of multi-filament yarns: II random properties over the length and size effect. Int J Solids Struct 43(3):435–458. https://doi.org/10.1016/j.ijsolstr.2005.06.062

Banholzer B, Brameshuber W, Jung W (2006) Analytical evaluation of pull-out tests the inverse problem. Cem Concr Compos 28(6):564–571. https://doi.org/10.1016/j.cemconcomp.2006.02.015

Banholzer B, Brameshuber W, Jung W (2005) Analytical simulation of pull-out teststhe direct problem. Cem Concr Compos 27(1):93–101. https://doi.org/10.1016/j.cemconcomp.2004.01.006

Banholzer B, Brockmann T, Brameshuber W (2006) Material and bonding characteristics for dimensioning and modelling of textile reinforced concrete (TRC) elements. Mater Struct 39(8):749–763. https://doi.org/10.1617/s11527-006-9140-x

Hegger J, Bruckermann O, Chudoba R (2004) 134. a smeared bond-slip relation for multi-filament yarns embedded in fine concrete. In: 6th International RILEM symposium on fibre reinforced concretes. RILEM Publications SARL, pp 1453–1462

Holler S, Butenweg C, Noh SY (2002) Numerical simulation of textile-reinforced concrete structures

Holler S, Butenweg C, Noh SY, Meskouris K (2004) Computational model of textile-reinforced concrete structures. Comput Struct 82(23):1971–1979. https://doi.org/10.1016/j.compstruc.2004.03.076

Hegger J, Will N, Bruckermann O, Voss S (2006) Loadbearing behaviour and simulation of textile reinforced concrete. Mater Struct 39(8):765–776. https://doi.org/10.1617/s11527-005-9039y

Jesse F (2006) Efficiency of multi filament reinforcement in cementitious composites. In: Brandt AM, Li VC, Marshall IH (eds) Brittle matrix composites, vol 8. Woodhead Publishing, Sawston, pp 275–284. https://doi.org/10.1533/9780857093080.275

Purnell P, Short NR, Page CL, Majumdar AJ (2000) Microstructural observations in new matrix glass fibre reinforced cement. Cem Concr Res 30(11):1747–1753. https://doi.org/10.1016/S00088846(00)00407-5

Peled A, Zaguri E, Marom G (2008) Bonding characteristics of multifilament polymer yarns and cement matrices. Compos Part A Appl Sci Manuf 39(6):930–939. https://doi.org/10.1016/j.compositesa.2008.03.012

Homoro O, Michel M, Baranger TN (2019) Pull-out response of glass yarn from ettringite matrix: Effect of preimpregnation and embedded length. Compos Sci Technol 170:174–182. https://doi.org/10.1016/j.compscitech.2018.11.045

Glinicki MA, Brandt AM (2007) Quantification of glass fibrecement interfacial properties by SEM-based push-out test. In: Proceedings of the 5th international RILEM workshop high performance fiber reinforced cement composites, Proc, vol 53, pp 343–355

Zhu W, Bartos PJM (1997) Assessment of interfacial microstructure and bond properties in aged GRC using a novel microindentation method. Cem Concr Res 27(11):1701–1711. https://doi.org/10.1016/S0008-8846(97)00155-5

Weichold O, Hojczyk M (2009) Size effects in multifilament glass-rovings: the influence of geometrical factors on their performance in textile-reinforced concrete. Text Res J 79(16):1438–1445. https://doi.org/10.1177/0040517508100628

Slama AC, Gallias JL, Fiorio B (2020) Study of the pull-out test of multifilament yarns embedded in cementitious matrix. J Compos Mater 55:169–185. https://doi.org/10.1177/0021998320946368

Head MK, Buenfeld NR (2006) Confocal imaging of porosity in hardened concrete. Cem Concr Res 36(5):896–911. https://doi.org/10.1016/j.cemconres.2005.06.006

Yio MHN, Mac MJ, Wong HS, Buenfeld NR (2015) 3d imaging of cement-based materials at submicron resolution by combining laser scanning confocal microscopy with serial sectioning. J Microsc 258(2):151–169. https://doi.org/10.1111/jmi.12228

Arganda-Carreras I, Kaynig V, Rueden C, Eliceiri KW, Schindelin J, Cardona A, Sebastian Seung H (2017) Trainable weka segmentation: a machine learning tool for microscopy pixel classification. Bioinformatics 33(15):2424–2426. https://doi.org/10.1093/bioinformatics/btx180

Bouasker M, Mounanga P, Turcry P, Loukili A, Khelidj A (2008) Chemical shrinkage of cement pastes and mortars at very early age: Effect of limestone filler and granular inclusions. Cem Concr Compos 30(1):13–22. https://doi.org/10.1016/j.cemconcomp.2007.06.004

Chen H, Wang P, Pan J, Lawi AS, Zhu Y (2021) Effect of alkali-resistant glass fiber and silica fume on mechanical and shrinkage properties of cement-based mortars. Construc Build Mater 307:125054. https://doi.org/10.1016/j.conbuildmat.2021.125054

Rath B, Deo S, Ramtekkar G (2017) Durable glass fiber reinforced concrete with supplimentary cementitious materials. Int J Eng 30(7):964–971

Saradar A, Tahmouresi B, Mohseni E, Shadmani A (2018) Restrained shrinkage cracking of fiber-reinforced highstrength concrete. Fibers 6(1):12. https://doi.org/10.3390/fib6010012

Acknowledgements

This work has been realized by the facilities of the Plateforme Microscopies and Analyses, Federation I-Mat (FR4122) of CY Cergy Paris Universit (France).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Slama, A.C., Gallias, J.L. & Fiorio, B. New visualization method to characterize the impregnation of a multifilament yarn in a cement matrix. Mater Struct 55, 21 (2022). https://doi.org/10.1617/s11527-021-01873-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-021-01873-w