Abstract

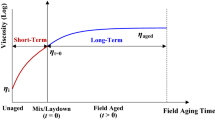

Aging has a significant effect on the performance of asphalt material. Reliable modelling of the change of asphalt mixture properties over time is crucial to evaluating and predicting the performance of the designed pavement. The objective of this study is to develop an aging model to accurately predict the cracking performance of asphalt mixtures over the pavement service life, as well as evaluate the aging susceptibility of mixtures over time. In this study, nine loose mixtures were conditioned in an oven at 95 °C for multiple durations to simulate different field aging times. The climatic aging index (CAI) developed by the National Cooperative Highway Research Program (NCHRP) 09-54 project was utilized to calculate the appropriate field aging durations corresponding to the different laboratory aging conditions. Complex modulus tests (E*) were conducted to measure the rheological properties of the conditioned mixtures and further construct the dynamic modulus and phase angle mastercurves. The mixture Glover–Rowe (G–Rm) parameter, incorporating both stiffness and relaxation capacity, was selected and used as the Aging Index Property to model the changes in mixture cracking properties with aging. The results of this study indicate that the developed mixture aging model can effectively capture the two aging reaction periods (fast and constant) of asphalt materials. The developed model can not only be used to evaluate the change of cracking properties over pavement service life, but also detect the aging susceptibility of asphalt mixtures.

Similar content being viewed by others

References

Laidler KJ (1987) Chemical kinetics, 3rd edn. Harper & Row, New York, p 42

Herrington PR, Patrick JE, Ball GF (1994) Oxidation of roading asphalts. Ind Eng Chem Res 33(11):2801–2809

Lau CK, Lunsford KM, Glover CJ, Davison RR, Bullin JA (1992) Reaction rates and hardening susceptibilities as determined from pressure oxygen vessel aging of asphalts. Transp Res Rec 1342:50–56

Davison RR, Bullin JA, Glover CJ, Chaffin JM, Peterson GD, Lunsford KM, Lin MS, Liu M, Ferry MA (1994) Verification of an asphalt aging test and development of superior recycling agent and asphalts. https://static.tti.tamu.edu/tti.tamu.edu/documents/1314-1F.pdf. Accessed 1 Aug 2019

Liu M, Lunsford KM, Davison RR, Glover CJ, Bullin JA (1996) The kinetics of carbonyl formation in asphalt. Am Inst Chem Eng J 42(4):1069–1076

Domke CH, Davison RR, Glover CJ (2000) Effect of oxygen pressure on asphalt oxidation kinetics. Ind Eng Chem Res 3:592–598

Glover CJ, Han R, Jin X, Prapaitrakul N, Cui Y, Rose A, Lawrence JJ, Padigala M, Arambula E, Park ES, Martin AE (2014) Evaluation of binder aging and its influence in aging of hot mix asphalt concrete. https://static.tti.tamu.edu/tti.tamu.edu/documents/0-6009-1.pdf. Accessed 1 Aug 2019

Glaser R, Turner TF, Loveridge JL, Salmans SL, Planche JP (2013) Fundamental properties of asphalts and modified asphalts, vol 3. Quarterly technical report, Federal Highway Administration (FHWA), Washington DC

Glaser R, Turner TF, Loveridge JL, Salmans SL, and Planche JP (2015) Fundamental properties of asphalts and modified asphalt, vol 3. Aging Master Curve (FP 10) and Aging Rate Model (FP 11). Technical white paper, Western Research Institute, Laramie, Wyoming

Elwardany MD, Yousefi Rad F, Castorena C, Kim YR (2017) Evaluation of asphalt mixture laboratory long-term aging methods for performance testing and prediction. Road Mater Pavement Des 18(sup1):28–61

Elwardany MD, Yousefi Rad F, Castorena C, Kim YR (2018) Climate-, depth-, and time-based laboratory aging procedure for asphalt mixtures. J Assoc Asphalt Paving Technol 87(0270–2932):467–512

Moraes R, Bahia HU (2015) Effect of mineral filler on changes in molecular size distribution of asphalt during oxidative ageing. Road Mater Pavement Des 16:55–72

Wu JT, Han WP, Airey G, Yusoff NIM (2014) The influence of mineral aggregates on bitumen ageing. Int J Pavement Res Technol 7(2):115–123

Petersen JC (2009) A review of the fundamentals of asphalt oxidation: chemical, physicochemical, physical property, and durability relationships. Transportation Research E-Circular (E-C140), Transportation Research Board, Washington, DC

Little DN, Epps JA, Sebaaly PE (2006) Hydrated lime in hot mix asphalt. National Lime Association. https://www.lime.org/lime-basics/uses-of-lime/construction/asphalt/. Accessed 1 Aug 2019

Recasens R, Martínez A, Jiménez F, Bianchetto H (2005) Effect of filler on the aging potential of asphalt mixtures. Transp Res Rec J Transp Res Board 1901:10–17

Huang SC, Petersen JC, Robertson R, Branthaver J (2002) Effect of hydrated lime on long-term oxidative aging characteristics of asphalt. Transportation Research Record: Journal of the Transportation Research Board, No. 1810, Transportation Research Board of the National Academies, Washington, DC, pp 17–24

Jones GM (1997) The effect of hydrated lime on asphalt in bituminous pavements. NLA Meeting, Utah DOT, Utah, USA

Petersen JC, Plancher H, Harnsberger PM (1987) Lime treatment of asphalt to reduce age hardening and improve flow properties, vol 56. Association of Asphalt Paving Technologists

Martin AE, Zhou F, Arambula E, Park ES, Chowdhury A, Kaseer F, Carvajal J, Hajj E, Daniel JS, Glover C (2015) The effects of recycling agents on asphalt mixtures with high ras and rap binder ratios. http://onlinepubs.trb.org/onlinepubs/nchrp/docs/NCHRP09-58_PhII_DraftInterimReport.pdf. Accessed 1 Aug 2019

Pournoman S, Hajj EY, Morian N, Martin AE (2018) impact of recycled materials and recycling agents on asphalt binder oxidative aging predictions. Transp Res Rec 2672(28):277–289

Oshone M, Sias JE, Dave EV, Epps Martin A, Kaseer F, Rahbar-Rastegar R (2019) Exploring master curve parameters to distinguish between mixture variables. Road Mater Pavement Des. https://doi.org/10.1080/14680629.2019.1633784

Glover CJ, Davison RR, Domke CH, Ruan Y, Juristyarini P, Knorr DB, Jung SH (2005) Development of a new method for assessing asphalt binder durability with field validation. https://static.tti.tamu.edu/tti.tamu.edu/documents/0-1872-2.pdf Accessed 1 Aug 2019

Rowe GM (2011) Evaluation of the relationship between asphalt binder properties and non-load related cracking. J Assoc Asphalt Paving Technol 80:649–662

Mensching DJ, Geoffrey MR, Daniel JS (2017) A mixture-based black space parameter for low-temperature performance of hot mixture asphalt. Road Mater Pavement Des 18:404–425

Rowe G, Sharrock M (2016) Cracking of asphalt pavements and the development of specifications with rheological measurements. Mater Sci. https://doi.org/10.14311/EE.2016.215

Bell CA., AbWahab Y, Cristi RE, Sognovske D (1994) selection of laboratory aging procedures for asphalt-aggregate mixtures. http://onlinepubs.trb.org/onlinepubs/shrp/SHRP-A-383.pdf Accessed 1 Aug 2019

Harrigan ET (2007) Simulating the effects of hot mix asphalt aging for performance testing and pavement structural design. http://www.trb.org/Publications/Blurbs/157804.aspx Accessed 1 Aug 2019

Blankenship PB, Anderson MA, King GN, Hanson DI (2010) A laboratory and field investigation to develop test procedures for predicting non-load associated cracking of airfield HMA pavements. https://www.eng.auburn.edu/research/centers/ncat/files/aaptp/Report.Final.06-01.pdf. Accessed 1 Aug 2019

Arega ZA, Bhasin A, De Kesel T (2013) Influence of extended aging on the properties of asphalt composites produced using hot and warm mix methods. Constr Build Mater 44(2013):168–174

Yousefi Rad F, Elwardany MD, Castorena C, Kim YR (2017) investigation of proper long-term laboratory aging temperature for performance testing of asphalt concrete. Constr Build Mater 147(2017):616–629

Kim RY, Castorena C, Elwardany M, Yousefi Rad F, Underwood S, Gundha A, Gudipudi, P, Farrer MJ, Glaser R (2018) long-term aging of asphalt mixtures for performance testing and prediction, http://www.trb.org/Publications/Blurbs/176937.aspx. Accessed 1 Aug 2019

Ozer H, Al-Qadi IL, Lambros J, El-Khatib A, Singhvi P, Doll B (2016) Development of the fracture-based flexibility index for asphalt concrete cracking potential using modified semi-circle bending test parameters. Constr Build Mater 115:390–401. https://doi.org/10.1016/j.conbuildmat.2016.03.144

Zhu Y, Dave EV, Rahbar-Rastegar R, Daniel JS, Zofka A (2017) Comprehensive evaluation of low temperature cracking fracture indices for asphalt mixtures. Road Mater Pavement Des 18(sup4):467–490. https://doi.org/10.1080/14680629.2017.1389085

Wang Y, Kim YR (2017) Development of a pseudo strain energy-based fatigue failure criterion for asphalt mixtures. Int J Pavement Eng 20(10):1182–1192. https://doi.org/10.1080/10298436.2017.1394100

Zhang R, Dave EV, Daniel JS (2019) Impact of aging on the viscoelastic properties and cracking behaviour of asphalt mixtures. Transp Res Rec J Transp Res Board. https://doi.org/10.1177/0361198119846473

Zhang R, Daniel JS, Dave EV (2018) Evaluation of viscoelastic properties and cracking behaviour of asphalt mixtures with laboratory aging. In: RILEM252-CMB-symposium on chemo mechanical characterization of bituminous materials. Springer, pp 33–38

Lane D (2003) Online statistics education: an interactive multimedia course of study. Rice University, Texas. http://onlinestatbook.com/. Accessed 1 Aug 2019

Petersen JC, Harnsberger P (1996) Asphalt aging: dual oxidation mechanism and its interrelationships with asphalt composition and oxidative age hardening. Transp Res Rec J Transp Res Board 1638:47–55

Petersen JC (1998) A dual, sequential mechanism for the oxidation of petroleum asphalts. Pet Sci Technol 16(9–10):1023–1059

Petersen JC, Glaser R (2011) Asphalt oxidation mechanisms and the role of oxidation products on age hardening revisited. Road Mater Pavement Des 12(4):795–819

Prapaitrakul N, Han R, Jin X, Glover CJ (2009) A transport model of asphalt binder oxidation in pavements. Road Mater Pavement Des 10(sup1):95–113. https://doi.org/10.1080/14680629.2009.9690238

Han R (2011) Improvement to a transport model of asphalt binder oxidation in pavements: pavement temperature modeling, oxygen diffusivity in asphalt binders and mastics, and pavement air void characterization. https://pdfs.semanticscholar.org/ebc2/e2d286c31f50f920c04741b5725e84e21d4d.pdf. Accessed 1 Aug 2019

Acknowledgements

The authors would like to acknowledge New Hampshire Department of Transportation (NHDOT) for sponsoring this study and the University of New Hampshire Center for Infrastructure Resilience to Climate (UCIRC). Findings and conclusions presented in this paper represent results of research interpreted by of authors and does not does not necessarily represent the views or policies of the project sponsors.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, R., Sias, J.E. & Dave, E.V. Development of a rheology-based mixture aging model for asphalt material cracking performance evaluation. Mater Struct 54, 150 (2021). https://doi.org/10.1617/s11527-021-01743-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-021-01743-5