Abstract

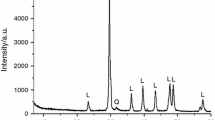

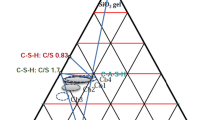

The benefits of partial replacement of Portland cement by limestone are well established. This study investigates the impact of zinc and butyl stearates, as water-repellent additives, on the compressive strength, flexural strength, water penetration, absorption, chloride migration, density, drying shrinkage, and thermal expansion of Portland Limestone Cement mortars. The contents of stearates in this work are 1%, 2%, 3%, 4%, 5% by mass of binder content. Spectroscopic analyses using scanning electron microscopy and X-ray diffraction revealed discrete changes in the derived cement composite microstructure. The results of hardened mortar evaluation showed a negligible effect of zinc stearate on durability performance. In contrast to that, incorporation of butyl stearate in the mixtures enhanced resistivity to water permeability and chloride migration.

Similar content being viewed by others

References

Bamforth PB, Price WF, Emerson M (1997) An international review of chloride ingress into structural concrete. Transport Research Laboratory, Contractor Report, UK, p 359

ACI Committee 212 (2016) Report on chemical admixtures for concrete. American Concrete Institute, p 43

Bensted J, Barnes P (2008) Structure and performance of cements, 2nd edn. Spon Press, Taylor & Francis Group, London, pp 158, 163, 194, 384

Sun J, Chen Z (2018) Influences of limestone powder on the resistance of concretes to the chloride ion penetration and sulfate attack. Powder Technol 338:728. https://doi.org/10.1016/j.powtec.2018.07.041

Dhir RK, Limbachiya MC, McCarthy MJ, Chaipanich A (2007) Evaluation of Portland limestone cements for use in concrete construction. Mater Struct 40:463. https://doi.org/10.1617/s11527-006-9143-7

Githachuri K, Alexander MG (2013) Durability performance potential and strength of blended Portland limestone cement concrete. Cem Concr Compos 39:117. https://doi.org/10.1016/j.cemconcomp.2013.03.027

Lu Z, Zhou X (2000) The waterproofing characteristics of polymer sodium carboxymethyl-cellulose. Cem Concr Res 30:230. https://doi.org/10.1016/S0008-8846(99)00233-1

Falchi L, Zendri E, Muller U, Fontana P (2015) The influence of water-repellent admixtures on the behaviour and the effectiveness of Portland limestone cement mortars. Cem Concr Compos 59:108. https://doi.org/10.1016/j.cemconcomp.2015.02.004

Report T (1980) A guide to the selection of admixtures for concrete. Concr Soc 18:28

Neville AM, Brooks JJ (2010) Concrete technology, 2nd edn. Prentice Hall, Harlow, p 158

Hewlett PC (2006) Lea’s chemistry of cement and concrete, 4th edn. Elsevier Butterworth-Heinemann, Amsterdam, pp 869, 887–890

Lagazzo A, Vicini S, Cattaneo C, Botter R (2016) Effect of fatty acid soap on microstructure of lime-cement mortar. Constr Build Mater 116:385. https://doi.org/10.1016/j.conbuildmat.2016.04.122

Maryoto A, Gan SB, Hermanto NIS, Setijadi R (2020) Effect of calcium stearate in the mechanical and physical properties of concrete with PCC and fly ash binders. Materials 13(6):1394. https://doi.org/10.3390/ma13061394

Naseroleslami R, Chari MN (2019) The effects of calcium stearate on mechanical and durability aspects of self-consolidating concretes incorporating silica fume/natural zeolite. Constr Build Mater 225:384–400. https://doi.org/10.1016/j.conbuildmat.2019.07.144

Lanzon M, Garciz-Ruiz PA (2008) Effectiveness and durability evaluation of rendering mortars made with metallic soaps and powdered silicone. Constr Build Mater 22:2309. https://doi.org/10.1016/j.conbuildmat.2007.10.001

Lanzon M, Martinez E, Mestre M, Madrid JA (2017) Use of zinc stearate to produce highly hydrophobic adobe materials with extended durability to water and acid-rain. Constr Build Mater 139:115. https://doi.org/10.1016/j.conbuildmat.2017.02.055

Rixom R, Mailvaganam N (2001) Chemical admixtures for concrete, 3rd edn. E & FN Spon, Taylor & Francis Group, London, p 164

BS EN 934-2. Admixtures for concrete, mortar and grout—part 2: concrete admixtures—definitions, requirements, conformity, marking and labelling

BS EN 197-1. Cement—part 1: composition, specifications and conformity criteria for common cements

BS EN 196-7. Methods of testing cement—part 7: methods of taking and preparing samples of cement

BS EN 196-1. Methods of testing cement—part 1: determination of strength

ASTM C157/C157M. Standard test method for length change of hardened hydraulic-cement mortar and concrete

BS EN 1770. Products and systems for the protection and repair of concrete structures—test methods, determination of the coefficient of thermal expansion

BS EN 1170-6. Precast concrete products—test method for glass-fibre reinforced cement—part 6. Determination of the absorption of water by immersion and determination of the dry density

TPN950/16/17292 Issue 1. In house test procedure—determination of depth of water penetration in hardened concrete or mortar

BS EN 12390-8. Testing hardened concrete. Depth of penetration of water under pressure

Report T (1988) Permeability testing of site concrete. Concr Soc 31:33

Nordtest method NT Build 492. Concrete, mortar and cement-based repair materials: chloride migration coefficient from non-steady-state migration experiments

XRD phase analysis software (2010–2011) Bruker AXS GmbH, Karlsruhe, Germany

Courard L, Michel F (2014) Limestone fillers cement based composites: effects of blast furnace slags on fresh and hardened properties. Constr Build Mater 51:439–445. https://doi.org/10.1016/j.conbuildmat.2013.10.076

Sezer GI (2012) Compressive strength and sulfate resistance of limestone and/or silica fume mortars. Constr Build Mater 26:613–618. https://doi.org/10.1016/j.conbuildmat.2011.06.064

Ramezanianpour AA, Ghiasvand E, Nickseresht I, Mahdikhani M, Moodi F (2009) Influence of various amounts of limestone powder on performance of Portland limestone cement concretes. Cem Concr Compos 31:715–720. https://doi.org/10.1016/j.cemconcomp.2009.08.003

Wang D, Shi C, Farzadnia N, Shi Z, Jia H (2018) A review on effects of limestone powder on the properties of concrete. Constr Build Mater 192:153–166. https://doi.org/10.1016/j.conbuildmat.2018.10.119

Ramachandran VS (1995) Concrete admixtures handbook, 2nd edn. Noyes Publications, New Jersey, p 355

Neville AM (2011) Properties of concrete, 5th edn. Prentice Hall, Tokyo, p 842

Maryoto A (2015) Improving microstructures of concrete using Ca(C18H35O2)2. Procedia Eng 125:631–637. https://doi.org/10.1016/j.proeng.2015.11.086

O’Donoghue V (2016) Shrinkage of concrete. Concr Advice Concr Soc 56:1

Bentz DP, Jensen OM, Hansen KK, Olesen JF, Stang H, Haecker CJ (2001) Influence of cement particle size distribution on early age autogenous strains and stresses in cement-based materials. J Am Ceram Soc 84(1):129–135. https://doi.org/10.1111/j.1151-2916.2001.tb00619.x

Cohen MD, Olek J, Dolch WL (1990) Mechanism of plastic shrinkage cracking in portland cement and portland cement-silica fume paste and mortar. Cem Concr Res 20(1):103–119. https://doi.org/10.1016/0008-8846(90)90121-D

Barrett T, Sun H, Villani C, Barcelo L, Weiss J (2014) Early-age shrinkage behaviour of Portland limestone cement. Concr Int 36:51–57

Wittmann FH, Beltzung F, Zhao TJ (2009) Shrinkage mechanisms, crack formation and service life of reinforced concrete structures. Int J Struct Eng 1(1):13–28. https://doi.org/10.1504/IJSTRUCTE.2009.030023

Beltzung F, Wittmann FH (2005) Role of disjoining pressure in cement based materials. Cem Concr Res 35:2364–2370. https://doi.org/10.1016/j.cemconres.2005.04.004

Palm S, Proske T, Rezvani M, Hainer S, Muller C, Graubner CA (2016) Cements with a high limestone content—mechanical properties, durability and ecological characteristics of the concrete. Constr Build Mater 119:316. https://doi.org/10.1016/j.conbuildmat.2016.05.009

BS EN 1992-1-1. Eurocode 2: design of concrete structures part 1-1: general rules and rules for buildings, pp 31–34

Maryoto A, Setijadi R, Widyaningrum A, Waluyo S (2020) Drying shrinkage of concrete containing calcium stearate, (Ca(C18H35O2)2), with ordinary Portland cement (OPC) as a binder: experimental and modelling studies. Molecules 25(21):4880. https://doi.org/10.3390/molecules25214880

Stolz HJ (2008) Oleochemicals—important additives for building protection. ZKG Int 61:78–86

BS EN 1992-3. Eurocode 2: design of concrete structures part 3: liquid retaining and containment structures, p 7

Bamforth PB (2018) Control of cracking caused by restrained deformation in concrete, CIRIA C766, London, p 46

Li S, Roy DM (1986) Investigation of relations between porosity, pore structure, and Cl-diffusion of fly ash and blended cement pastes. Cem Concr Res 16:756. https://doi.org/10.1016/0008-8846(86)90049-9

Dhandapani Y, Sakthivel T, Santhanam M, Gettu R, Pillai RG (2018) Mechanical properties and durability performance of concretes with limestone calcined clay cement. Cem Concr Res 107:145. https://doi.org/10.1016/j.cemconres.2018.02.005

Halamickova P, Detwiler RJ, Bentz DP, Garboczi EJ (1995) Water permeability and chloride ion diffusion in Portland cement mortars: relationship to sand content and critical pore diameter. Cem Concr Res 25(4):801. https://doi.org/10.1016/0008-8846(95)00069-O

Tsivilis S, Tsantilas J, Kakali G, Chaniotakis E, Sakellariou A (2003) The permeability of Portland limestone cement concrete. Cem Concr Res 33:1468. https://doi.org/10.1016/S0008-8846(03)00092-9

Argiz C, Sanjuan MA, Muñoz-Martialay R (2014) Effect of the aggregate grading on the concrete air permeability. Mater Constr 64(315):1–6. https://doi.org/10.3989/mc.2014.07213

Yang H, Liu R, Zheng Z, Liu H, Gao Y, Liu Y (2018) Earth and environmental science 108(2):1–6. https://doi.org/10.1088/1755-1315/108/2/022067

Panesar DK, Zhang R (2020) Performance comparison of cement replacing materials in concrete: limestone fillers and supplementary cementing materials—a review. Constr Build Mater 251:1–15. https://doi.org/10.1016/j.conbuildmat.2020.118866

Sawada K, Konaka M (2004) Characterization of fine metallic soap particles by X-ray diffraction, differential scanning calorimetry, and specific surface area analysis. J Oleo Sci 53(12):627–640. https://doi.org/10.5650/jos.53.627

Vold RD, Hattiangdi GS (1949) Characterization of heavy metal soaps by X-ray diffraction. Ind Eng Chem 41(10):2311–2320. https://doi.org/10.1021/ie50478a056

Acknowledgements

The authors gratefully acknowledge the help of Dr. T. Palladas (Dept. Chem. Eng., AUTH), for carrying out X-ray diffractometry measurements on generated cement mortar samples and mixtures thereof.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Malakopoulos, A., Chatzigeorgiou, M., Boukos, N. et al. Durability performance of Portland limestone cement mortar containing butyl and zinc stearate admixtures. Mater Struct 54, 60 (2021). https://doi.org/10.1617/s11527-021-01638-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-021-01638-5