Abstract

Considering the significance of sulfate attack to structure durability and frequent existence of multiaxial loadings, it is relevant to study the triaxial mechanical behavior of sulfate-deteriorated cementitious materials. The triaxial compression tests with three confining pressures were conducted in previous study. To give a reliable constitutive model, this research investigated the triaxial mechanical behavior of sulfate-deteriorated mortar in experimental and modeling aspects. All stress–strain curves of the mortar samples immersed in 5% Na2SO4 solution up to 270 d were shown and analyzed. The ingress of sulfate decreased the axial strain at improvement stage, but slightly increased the strain at deterioration stage. The volume of mortar sample changed from contraction to dilation with loading, indicating a non-associated flow rule. A nearly linear relationship between the square root of triaxial failure stress and elastic modulus of mortar was observed, proved by other research results as well. The lateral confinement attenuated the negative effect of sulfate deterioration on the two mechanical indexes. On the basis of elastoplasticity theory and experimental results, an elastoplastic model considering sulfate deterioration was proposed. The effect of sulfate deterioration was implemented to the elastic modulus, failure criterion and hardening law through 2nd polynomial. Numerical simulations showed that the proposed model can well reproduce the compression behavior of sulfate-deteriorated mortar with different confining pressures.

Similar content being viewed by others

Availability of data and material

Could be available if required.

References

Ramezanianpour AM, Hooton RD (2013) Sulfate resistance of Portland-limestone cements in combination with supplementary cementitious materials. Mater Struct 46:1061–1073

Kunther W, Lothenbach B, Scrivener KL (2013) Deterioration of mortar bars immersed in magnesium containing sulfate solutions. Mater Struct 46:2003–2011

Yu XT, Chen D, Feng JR, Zhang Y, Liao YD (2018) Behavior of mortar exposed to different exposure conditions of sulfate attack. Ocean Eng 157:1–12

Whittaker M, Black L (2015) Current knowledge of external sulfate attack. Adv Cem Res 27:532–545

Lothenbach B, Bary B, Le Bescop P, Schmidt T, Leterrier N (2010) Sulfate ingress in Portland cement. Cem Concr Res 40:1211–1225

Yu XT, Zhu YW, Liao YD, Chen D (2016) Study of the evolution of properties of mortar under sulfate attack at different concentrations. Adv Cem Res 28:617–629

Haufe J, Vollpracht A (2019) Tensile strength of concrete exposed to sulfate attack. Cem Concr Res 116:81–88

Zhu J, Cao Y, Chen J (2013) Study on the evolution of dynamic mechanics properties of cement mortar under sulfate attack. Constr Build Mater 43:286–292

Verástegui-Flores RD, Di Emidio G (2014) Impact of sulfate attack on mechanical properties and hydraulic conductivity of a cement-admixed clay. Appl Clay Sci 101:490–496

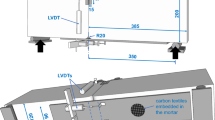

Chen D, Yu X, Guo M, Liao Y, Ouyang F (2017) Study on the mechanical properties of the mortars exposed to the sulfate attack of different concentrations under the triaxial compression with constant confining pressure. Constr Build Mater 146:445–454

Luo W, Jin XG, Zhang ZY (2019) Triaxial test on concrete material containing accelerators under physical sulphate attack. Constr Build Mater 206:641–654

Sfer D, Carol I, Gettu R, Etse G (2002) Study of the behavior of concrete under triaxial compression. J Eng Mech 128:156–163

Pietruszczak S, Jiang J, Mirza FA (1988) An elastoplastic constitutive model for concrete. Int J Solids Struct 24:705–722

Zaman M, Najjar YM, Faruque MO (1993) Modelling of stress-strain behaviour of plain concrete using a plasticity framework. Mater Struct 26:129–135

Shang H, Song Y (2008) Behavior of air-entrained concrete under the compression with constant confined stress after freeze–thaw cycles. Cem Concr Compos 30:854–860

Yurtdas I, Burlion N, Shao JF (2015) Evolution of mechanical behaviour of mortar with re-saturation after drying. Mater Struct 48:3343–3355

Xie SY, Shao JF, Burlion N (2008) Experimental study of mechanical behaviour of cement paste under compressive stress and chemical degradation. Cem Concr Res 38:1416–1423

GB 178–1977 (2006) Standard sand for testing strength of hydraulic cement mortars. Standardization Administration of the People’s Republic of China, Beijing

GB, T 50081–2002 (2003) Standard for test methods of mechanical properties on ordinary concrete. Standardization Administration of the People’s Republic of China, Beijing

ASTM C348 (2014) Standard test method for flexural strength of hydraulic-cement mortars. ASTM International, West Conshohocken

ASTM C349 (2014) Standard test method for compressive strength of hydraulic-cement mortars (using portions of prisms broken in flexure). ASTM International, West Conshohocken

Carde C, François R (1997) Effect of the leaching of calcium hydroxide from cement paste on mechanical and physical properties. Cem Concr Res 27:539–550

Shah SP, Chandra S (1968) Critical stress, volume change, and microcracking of concrete. ACI J Proc 65:770–781

ACI 318–05 (2005) Building code requirements for structural concrete. American Concrete Institute, Detroit

Shao JF, Zhu QZ, Su K (2003) Modeling of creep in rock materials in terms of material degradation. Comput Geotech 30:549–555

Imran I, Pantazopoulou SJ (1996) Experimental study of plain concrete under triaxial stress. ACI Mater J 93:589–601

Lu X, Hsu CT (2006) Behavior of high strength concrete with and without steel fiber reinforcement in triaxial compression. Cem Concr Res 36:1679–1685

Farnam Y, Moosavi M, Shekarchi M, Babanajad SK, Bagherzadeh A (2010) Behaviour of slurry infiltrated fibre concrete (SIFCON) under triaxial compression. Cem Concr Res 40:1571–1581

Ren GM, Wu H, Fang Q, Liu JZ, Gong ZM (2016) Triaxial compressive behavior of UHPCC and applications in the projectile impact analyses. Constr Build Mater 113:1–14

Mohamad-Hussein A, Shao JF (2007) Modelling of elastoplastic behaviour with non-local damage in concrete under compression. Comput Struct 85:1757–1768

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant Number 51579087); the Fundamental Research Funds for the Central Universities (Grant Numbers 2017B695X14, 2018B41414); the “111” Project (Grant Number B12032); and the Postgraduate Research & Practice Innovation Program of Jiangsu Province (grant number KYCX17_0447).

Funding

1. National Natural Science Foundation of China (grant number 51579087); 2. Fundamental Research Funds for the Central Universities (grant numbers 2017B695X14); 3. Fundamental Research Funds for the Central Universities (grant numbers 2018B41414); 4. “111” Project (grant number B12032); 5. Postgraduate Research & Practice Innovation Program of Jiangsu Province (Grant Number KYCX17_0447).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Code availability

Custom code.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xiaotong, Y., Chousheng, L., Yazhou, Z. et al. Experimental and modeling study on the triaxial mechanical behavior of sulfate-deteriorated mortar. Mater Struct 53, 121 (2020). https://doi.org/10.1617/s11527-020-01555-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-020-01555-z