Abstract

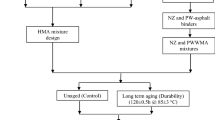

This paper presents the results of a study of some compounds capable of absorbing water into their structure (silica gel), as potential foaming binders. Asphalt mixtures were manufactured at different manufacturing and compaction temperatures, using four different silica gels. Static and dynamic tests were carried out to determine their behavior in asphalt mixtures. The results were compared with those obtained using hot-mix asphalt and warm-mix asphalt manufactured with zeolite. The lab results showed a similar behavior of asphalt mixtures containing either silica gel or zeolite.

Similar content being viewed by others

References

Sanchez-Alonso E, Castro-Fresno D, Vega-Zamanillo A, Rodriguez-Hernandez J (2011) Sustainable asphalt mixes: use of additives and recycled materials. Balt J Road Bridge E 6(4):249–257. https://doi.org/10.3846/bjrbe.2011.32

Rodríguez Maldonado JA (2004) [on line]. Hidrogenólisis e hidrotratamiento de residuos de vacío de petróleo tipo maya. PhD Thesis. Departamento de Ingeniería Química y Alimentos, Escuela de Ingeniería. Universidad de las Américas Puebla (México). http://catarina.udlap.mx/u_dl_a/tales/documentos/leip/rodriguez_m_ja/capitulo4.pdf. Accessed Apr 2012

Button JW, Estakhri C, Wimsatt A (2007) A synthesis of warm-mix asphalt. Texas Department of Transportation and the Federal Highway Administration. Report No FHWA/TX 07/0-5597-1

Hurley GC, Prowell BD (2005) Evaluation of Aspha-Min® for the use in warm mix asphalt. National Center for Asphalt Technology (NCAT). Report 05-04

Akisetty CK, Lee S-J, Amirkhanian SN (2009) Effects of compaction temperature on volumetric properties of rubberized mixes containing warm-mix additives. J Mater Civil Eng 21(8):409–415. https://doi.org/10.1061/(ASCE)0899-1561(2009)21:8(409)

Tao M, Mallick RB (2009) Effects of warm-mix asphalt additives on workability and mechanical properties of reclaimed asphalt pavement material. Transp Res Rec 2126:151–160. https://doi.org/10.3141/2126-18

Sengoz B, Topal A, Gorkem C (2013) Evaluation of natural zeolite as warm mix asphalt additive and its comparison with other warm mix additives. Constr Build Mater 43:242–252. https://doi.org/10.1016/j.conbuildmat.2013.02.026

Xu S, Xiao F, Amirkhaniana S, Singh D (2017) Moisture characteristics of mixtures with warm mix asphalt technologies—a review. Constr Build Mater 142:148–161. https://doi.org/10.1016/j.conbuildmat.2017.03.069

De Visscher J, Vervaecke F, Vanekstraete A, Soenen H, Tanghe T, Redelius P (2010) Asphalt production at reduced temperatures using zeolites and the impact on asphalt performance. Road Mater Pavement Des 11(1):65–81. https://doi.org/10.1080/14680629.2010.9690260

Woszuk A, Franus W (2016) Properties of the warm mix asphalt involving clinoptilolite and Na-P1 zeolite additives. Constr Build Mater 114:556–563. https://doi.org/10.1016/j.conbuildmat.2016.03.188

Hossain Z, Zaman M, O’Rear EA, Chen D-H (2011) Effectiveness of Advera® in warm mix asphalt. In: Proceedings of the GeoHunan international conference—emerging technologies for material, design, rehabilitation, and inspection of roadway pavements, 2011, June 9–11, Hunan, China. Geotechnical Special Publication 218: 9–16

Topal A, Sengoz B, Kok BV, Yilmah M, Agazadeh Dokhandari P, Oner J, Kaya D (2014) Evaluation of mixture characteristics of warm mix asphalt involving natural and synthetic zeolite additives. Constr Build Mater 57:38–44. https://doi.org/10.1016/j.conbuildmat.2014.01.093

Wu S, Li X (2017) Evaluation of effect of curing time on mixture performance of Advera warm mix asphalt. Constr Build Mater 145:62–67. https://doi.org/10.1016/j.conbuildmat.2017.03.240

Goh SW, You Z (2011) Evaluation of warm mix asphalt produced at various temperatures through dynamic modulus testing and four point beam fatigue testing. In: Proceedings of the GeoHunan international conference—pavements and materials: recent advances in design, testing, and construction, 2011, June 9–11, Hunan, China. Geotechnical Special Publication 212: 123–130

Sáenz MC, Báez Quintero CA, Díaz Velásquez JJ, Rodríguez Niño G (2007) Estudio de las variables de reacción en la síntesis de silica gel adsorbente [reaction parameter study for the chemical synthesis of adsorbent silica gel]. Ingeniería e Investigación 27(2):44–50

Peña J, Cardona E, Rios L (2008) Synthesis of silicon oxide with high superficial area and porosity through sol–gel technique using glycerol and glyceryl monostearate as templates [Síntesis de óxidos de silicio de altas área superficial y porosidad empleando el metodo sol-gel en presencia de glicerol y monoestearato de glicerilo como estructurantes]. Dyna 75(156):207–216

Goedecke R (2011) Fluidverfahrenstechnik. Grundlagen, methodik, technik, praxis. Ed.Wiley-VCH, Weinheim

Fortier L, Côté S, St-Laurent H, Bernier S, Couture A (2001) Process for the regeneration of used silica gel. Sylicicle Inc. (Quebec, CA). US Patent: US 6248683B1. Date of patent: 06/19/2001

Chemicalbook Inc. (2017) Silica gel basic information. CAS number: 112926-00-8. IOP Publishing ChemicalBook web. https://www.chemicalbook.com/ProductChemicalPropertiesCB1199389_EN.htm. Accessed 29 Apr 2018

UNE EN 12697-30 (2013) Bituminous mixtures. Test methods for hot mix asphalt, part 30: specimen preparation by impact compactor

UNE EN 12697-8 (2003) Bituminous mixtures. Test methods for hot mix asphalt, part 8: determination of void characteristics of bituminous specimens

Riberiro FE (2012) Zeolite and water slurries for asphalt concrete pavement. US Patent: US 2012/0180702A1. Date of patent: 07/19/2012

Gálvez AV, Aravena EL, Mondaca RL (2006) Isotermas de adsorción en harina de maíz (Zea mays L.). Food Sci Technol 26(4):821–827. https://doi.org/10.1590/S0101-20612006000400017

ALOthman ZA (2012) A review: fundamental aspects of silicate mesoporous materials. Materials 5:2874–2902. https://doi.org/10.3390/ma5122874

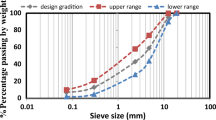

Coleccion normativa tecnica (2015) Pliego de prescripciones tecnicas generales para obras de carreteras y puentes (PG-3). Articulo 542: Mezclas bituminosas en caliente tipo hormigon bituminoso. Ministerio de Fomento. Espana, 2015

DelRio-Prat M, Vega-Zamanillo A, Castro-Fresno D, Calzada-Perez MA (2010) Energy consumption during compaction with a Gyratory Intensive Compactor Tester. Estimation models. Constr Build Mater 25(2):979–986. https://doi.org/10.1016/j.conbuildmat.2010.06.083

UNE EN 12697-31 (2008) Bituminous mixtures. Test methods for hot mix asphalt, part 31: specimen preparation by gyratory compactor

UNE EN 12697-10:2003 (2003) Bituminous mixtures. Test methods for hot mix asphalt, part 10: compactability

UNE EN 12697-12 (2009) Bituminous mixtures. Test methods for hot mix asphalt, part 12: determination of the moisture sensitivity of bituminous specimens

UNE EN 12697-23 (2004) Bituminous mixtures. Test methods for hot mix asphalt, part 23: determination of the indirect tensile strength of bituminous specimens

UNE EN 12697-26 (2012) Bituminous mixtures. Test methods for hot mix asphalt, part 26: stiffness

UNE EN 12697-22 (2008) Bituminous mixture: test methods for hot mix asphalts, part 22: Wheel tracking

UNE EN 12697-33 (2007) Bituminous mixture: test methods for hot mix asphalts, part 33: specimen prepared by roller compactor

Moghaddam TB, Karim MR, Abdelaziz M (2011) A review on fatigue and rutting performance of asphalt mixes. Sci Res Essays 6(4):670–682. https://doi.org/10.5897/SRE10.946

UNE EN 12697-24 (2013) Bituminous mixture: test methods for hot mix asphalts, part 24: resistance to fatigue

García Martínez J (2003) Adsorción e intercambio iónico en zeolitas. In: Materiales zeolíticos: síntesis, propiedades y aplicaciones, García Martínez J, Pérez Pariente J (eds) Universidad de Alicante: Colección Textos Docentes, 2003, ISBN 978-84-7908-722-7. https://publicaciones.ua.es/va/detall.php?idet=621. Accessed May 2012

Flores J, Maubert A, Martín N (2006) Evaluación de los intercambios iónicos en una zeolita natural Mexicana para la separación de N2–O2 en el aire atmosférico. Revista Mexicana de Ingeniería Química 5(2):119–129

Hernández MA, Rojas F, Corona L, Lara VH, Portillo R, Salgado MA, Petranoskii VH (2005) Evaluación de la porosidad de zeolitas naturales por medio de curvas diferenciales de adsorción. Revista Internacional de Contaminación Ambiental 21(2):71–81

Groen JC, Peffer LAA, Pérez-Ramírez J (2003) Pore size determination in modified micro- and mesoporous materials. Pitfalls and limitations in gas adsorption data analysis. Micropor Mesopor Mater 60:1–17. https://doi.org/10.1016/S1387-1811(03)00339-1

Silva HMRD, Oliveira JRM, Peralta J, Zoorob SE (2010) Optimization of warm mix asphalts using different blends of binders and synthetic paraffin wax contents. Constr Build Mater 24(9):1621–1631. https://doi.org/10.1016/j.conbuildmat.2010.02.030

Acknowledgements

The research presented herein was sponsored by the Research Office of Universidad de La Frontera (DIUFRO) under the Project Number DI15-0089.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Sanchez-Alonso, E., Vega-Zamanillo, A., Calzada-Perez, M.A. et al. Mechanical behavior of asphalt mixtures containing silica gels as warm additives. Mater Struct 51, 82 (2018). https://doi.org/10.1617/s11527-018-1214-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-018-1214-z