Abstract

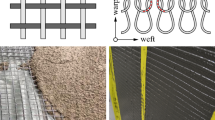

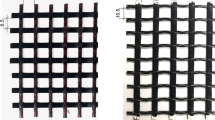

In textile reinforced concrete (TRC), the yarns of the textiles are inherently wavy due to the manufacturing process. In most structural applications, this leads to delayed activation of textiles during loading and affects the composite performance negatively. In this context, the paper reports on the significance of mechanically prestressing or stretching the textiles before casting the TRC towards enhancing its load-carrying ability, which has been assessed by comparing the responses of specimens with textiles placed by manual and mechanical stretching. Studies were carried out to determine the uniaxial tensile behaviour of TRC with two types of alkali-resistant glass textiles, woven and bonded and their combinations. TRC with mechanically-stretched woven textile exhibits better performance compared to that of the manually stretched textile, in terms of load-carrying ability though the elongation at failure could be compromised for specimens with bonded textiles. Mechanically stretched textile lead to pronounced strain hardening behaviour, enhancement in the stress at first cracking and stress at peak, which also increase as the number of layers increases. The failure of TRC with manually stretched textile occurs with the pullout of the textile from the matrix contrasting with the rupture of textile when mechanically stretched. X-ray tomography images of the internal structure of TRC further revealed that there is less frictional bond loss and debonding of textile from the matrix for mechanically stretched textile.

Similar content being viewed by others

References

Peled A, Mobasher B (2007) Tensile behavior of fabric cement-based composites: pultruded and cast. J Mater Civ Eng 19(4):340–348

Barhum R, Mechtcherine V (2013) Influence of short dispersed and short integral glass fibres on the mechanical behaviour of textile-reinforced concrete. Mater Struct 46(4):557–572

Peled A, Bentur A (2000) Geometrical characteristics and efficiency of textiles for reinforcing composites. Cem Concr Res 30(5):781–790

Kruger M, Ozbolt J, Reinhardt HW (2003) A new 3D discrete bond model to study the influence of bond on structural performance of thin reinforced and prestressed concrete plates. In: Naaman AE, Reinhardt HW (eds) Proceedings of the fourth international RILEM workshop on high performance fibre reinforced cement composites (HPFRCC4). RILEM Publications, Ann Arbor, pp 49–63

Reinhardt HW, Krüger M (2004) Prestressed concrete plates with high strength fabrics. In: PRO 39: proceedings of the sixth international RILEM symposium on fibre reinforced concretes (FRC) (BEFIB 2004), RILEM Publications, Paris, pp 187–196

Mayer C, Vilkner G (2003) Glass concrete thin sheets prestressed with aramid fibre mesh. In: Naaman AE, Reinhardt HW (eds) Proceedings of the fourth international RILEM workshop on high performance fibre reinforced cement composites (HPFRCC4), vol 1. RILEM Publications, Ann Arbor, pp 325–336

Peled A, Mobasher B (2005) Pultruded fabric cement composites. ACI Mater J 102(1):15–23

Peled A, Mobasher B, Sueki S (2004) Technology methods in textile cement-based composites. In: Kovler K, Marchand J, Mindess S, Weiss J (eds) Proceedings of International RILEM symposium on concrete science and engineering: a tribute to Arnon Bentur. RILEM Publications, Paris, pp 187–202

Mobasher B (2011) Mechanics of fibre and textile reinforced composites. CRC Press, Boca Raton

Brameshüber W (2006) Textile reinforced concrete. State-of-the-Art Report of RILEM TC 201-TRC, RILEM Report-36. RILEM Publications, Paris

Peled A, Bentur A (2003) Mechanisms of fabric reinforcements of cement matrices: effect of fabric geometry and yarn properties. In: Proceedings of the 2nd colloquium on textile reinforced structures (CTRS2), Dresden, pp 283–298

Reinhardt HW, Krüger M, Große CU (2003) Concrete prestressed with textile fabric. J Adv Concr Technol 1(3):231–239

Peled A (2007) Pre-tensioning of fabrics in cement-based composites. Cem Concr Res 37(5):805–813

Gopinath S (2017) Development of fabric reinforced concrete for flexural strengthening of RC beams. Ph.D Thesis, Department of Civil Engineering, IIT Madras, India

Brameshüber W (2016) Recommendation of RILEM TC 232-TDT: uniaxial tensile test: test method to determine the load-bearing behavior of tensile specimens made of textile reinforced concrete. Mater Struct 49(12):4923–4927

Acknowledgements

The authors thank the staff of the Computational Structural Mechanics Group & Fatigue and Fracture laboratory of CSIR-SERC for the support rendered for conducting experiments. Thanks are due to Prof. Krishnan Balasubramanian and Mr. Raguvarun Kannaiyan of the Centre for Non-Destructive Evaluation, IIT Madras, for advising and facilitating the X-ray tomography.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Gopinath, S., Gettu, R. & Iyer, N.R. Influence of prestressing the textile on the tensile behaviour of textile reinforced concrete. Mater Struct 51, 64 (2018). https://doi.org/10.1617/s11527-018-1194-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-018-1194-z