Abstract

Sprayed steel fibre reinforced concrete (SSFRC) is a material that tends to present anisotropy, due to the action of the spraying process inducing preferential fibre orientation. Despite numerous applications worldwide since the 1980s, no study has been found of the assessment of fibre distribution and its influence on the residual tensile strength of SSFRC. This work addresess this issue from a quantitative standpoint through an experimental programme with specimens extracted in various orientations within a SSFRC panel. The fibre content and 3D orientation were quantified using the inductive method and correlated with an indirect tensile behaviour for the same specimen with the Barcelona test. The results confirm the high level of anisotropy of SSFRC. The fibre orientation number parallel to the spraying direction is three times bigger than that found in the perpendicular direction. Similar differences were observed between the residual tensile response measured in those directions. Comparison of test results suggest that the preferential fibre orientation creates weaker planes that favours the increase of crack opening at lower load levels.

Similar content being viewed by others

References

Edgington J, Hannant DJ (1972) Steel fibre reinforced concrete. The effect on fibre orientation of compaction by vibration. Matériaux Constr 5(1):41–44

Ferrara L, Ozyurt N, di Prisco M (2011) High mechanical performance of fibre reinforced cementitious composites: the role of ‘“casting-flow induced”’ fibre orientation. Mater Struct 44(1):109–128

Blanco A, Pujadas P, de la Fuente A, Cavalaro SHP, Aguado A (2015) Assessment of the fibre orientation factor in SFRC slabs. Compos Part B 68:343–354

Laranjeira F, Aguado A, Molins C, Grünewald S, Walraven J, Cavalaro S (2012) Framework to predict the orientation of fibers in FRC: a novel philosophy. Cem Concr Res 42(6):752–768

Gettu R, Gardner DR, Saldívar H, Barragán BE (2005) Study of the distribution and orientation of fibers in SFRC specimens. Mater Struct 38(1):31–37

Stroeven P (1977) The analysis of fibre distributions in fibre reinforced materials. J Microsc 111(3):283–295

Stähli P, Custer R, van Mier JGM (2008) On flow properties, fibre distribution, fibre orientation and flexural behaviour of FRC. Mater Struct 41(1):189–196

Barnett SJ, Lataste J, Parry T, Millard SG, Soutsos MN (2010) Assessment of fibre orientation in ultra high performance fibre reinforced concrete and its effect on flexural strength. Mater Struct 43(7):1009–1023

Fédération Internationale du Béton (2013) Fib model code for concrete structures 2010. Lausanne

Blanco A, Cavalaro S, de la Fuente A, Grünewald S, Blom CBM, Walraven JC (2015) Application of FRC constitutive models to modelling of slabs. Mater Struct 48(9):2943–2959

Serna P, Arango S, Ribeiro T, Núñez AM, Garcia-Taengua E (2009) Structural cast-in-place SFRC: technology, control criteria and recent applications in spain. Mater Struct 42(9):1233–1246

Armelin HS, Helene P (1995) Physical and mechanical properties of steel fiber reinforced dry-mix shotcrete. ACI Mater J 92(3):258–267

Robins PJ, Austin SA (1985) Core point-load test for steel fibre reinforced concrete. Mag Concr Res 37(133):238–242

Robins PJ, Austin S, Jones PA (2003) Spatial distribution of steel fibres in sprayed and cast concrete. Mag Concr Res 55(3):225–235

Banthia N, Trottier J, Beaupré D (1994) Steel-fiber-reinforced wet-mix shotcrete: comparisons with cast concrete. J Mater Civ Eng 6(3):430–437

Segura-Castillo L, Aguado De Cea A (2012) Bi-layer diaphragm walls: evolution of concrete-to-concrete bond strength at early ages. Constr Build Mater 31:29–37

Segura-Castillo L (2013) Bi-layer diaphragm walls: experimental and numerical analysis. Universidad Politéncia de Cataluña, Barcelona

AENOR (2006) UNE-EN 14488-1:2006 Testing sprayed concrete—part 1: sampling fresh and hardened concrete

Krenchel H (1975) Fibre spacing and specific fibre surface. In: Proceedings of RILEM symposium on fibre reinforced cement and concrete. pp 69–79

Soroushian P, Lee C-D (1990) Distribution and orientation of fibers in steel fiber reinforced concrete. ACI Mater J 87(5):433–439

Kooiman AG (2000) Modelling steel fibre reinforced concrete for structural design. Delft University of Technology, Delft

Barragán B (2002) Failure and toughness of steel fiber reinforced concrete under tension and shear. Universitat Politècnica de Catalunya

Grünewald S (2004) Performance-based design of self-compacting fibre reinforced concrete. Delft University of Technology, Delft

Pujadas P, Blanco A, Cavalaro SHP, de la Fuente A, Aguado A (2014) Multidirectional double punch test to assess the post-cracking behaviour and fibre orientation of FRC. Constr Build Mater 58:214–224

Torrents JM, Blanco A, Pujadas P, Aguado A, Juan-García P, Sánchez-Moragues MÁ (2012) Inductive method for assessing the amount and orientation of steel fibers in concrete. Mater Struct 45(10):1577–1592

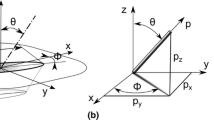

Cavalaro SHP, López R, Torrents JM, Aguado A (2014) Improved assessment of fibre content and orientation with inductive method in SFRC. Mater Struct 48(6):1859–1873

Cavalaro SHP, López-Carreño R, Torrents JM, Aguado A, Juan-García P (2015) Assessment of fibre content and 3D profile in cylindrical SFRC specimens. Mater Struct

Orbe A, Cuadrado J, Losada R, Rojí E (2012) Framework for the design and analysis of steel fiber reinforced self-compacting concrete structures. Constr Build Mater 35:676–686

EN 14651 (2005) Test method for metallic fibre concrete—measuring the flexural tensile strength (limit of proportionality (LOP), residual)

NBN B 15-238 (1992) Test on fibre reinforced concrete—bending test on prismatic simples. Norme Belge, Institut Belge de Normalisation, Brussels (in French)

EFNARC (1996) European specification for sprayed concrete, European federation of producers and applicators of specialist products for structures

ASTM C1550-10a (2012) Standard test method for flexural toughness of fiber reinforced concrete (using centrally loaded round panel). ASTM Stand. pp. 1–14

Bernard ES (2002) Correlations in the behaviour of fibre reinforced shotcrete beam and panel specimens. Mater Struct 35(3):156–164

Molins C, Aguado A, Saludes S (2009) Double punch test to control the energy dissipation in tension of FRC (Barcelona test). Mater Struct 42(4):415–425

di Prisco M, Ferrara L, Lamperti MGL (2013) Double edge wedge splitting (DEWS): an indirect tension test to identify post-cracking behaviour of fibre reinforced cementitious composites. Mater Struct 46:1893–1918

AENOR (2010) UNE 83515—fibre reinforced concrete. Determination of cracking strength, ductility and residual tensile strength. Barcelona Test. p 10

Blanco A, Pujadas P, Cavalaro S, De La Fuente A, Aguado A (2014) Constitutive model for fibre reinforced concrete based on the Barcelona test. Cem Concr Compos 53:327–340

Pujadas P, Blanco A, Cavalaro S, de la Fuente A, Aguado A (2013) New analytical model to generalize the Barcelona test using axial displacement. J Civ Eng Manag 19(2):259–271

Aire C, Molins C, Aguado A (2013) Ensayo de doble punzonamiento para concreto reforzado con fibra: efecto del tamaño y origen de la probeta. Concreto y Cem Investig y Desarro 5(1):17–31

Carmona Malatesta S, Aguado de Cea A, Molins Borrell C (2012) Generalization of the Barcelona test for the toughness control of FRC. Mater Struct 45(7):1053–1069

Ferrara L, Faifer M, Toscani S (2012) A magnetic method for non destructive monitoring of fiber dispersion and orientation in steel fiber reinforced cementitious composites—part 1: method calibration. Mater Struct 45(4):575–589

di Prisco M, Plizzari G, Vandewalle L (2009) Fibre reinforced concrete: new design perspectives. Mater Struct 42(9):1261–1281

Acknowledgements

The authors would like to thank the Spanish Ministry of Science and Innovation for the economic support received through Research Project IPT F-00339 FIBHAC. The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Segura-Castillo, L., Cavalaro, S.H.P., Goodier, C. et al. Fibre distribution and tensile response anisotropy in sprayed fibre reinforced concrete. Mater Struct 51, 29 (2018). https://doi.org/10.1617/s11527-018-1156-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-018-1156-5