Abstract

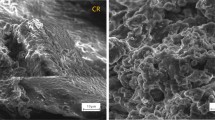

Crumb rubber is preliminarily mixed with asphalt in wet process to produce ductile and elastic asphalt rubber (AR), which has been extensively used in high performance bituminous mixtures for road pavement. Epoxy asphalt is a thermosetting polymer modified asphalt with excellent performance and has been widely applied on the pavement of steel bridge decks. Epoxy asphalt rubber (EAR) was prepared by mixing AR with the epoxy (EP). The effect of AR concentration on the phase-separated morphology, viscosity, thermal stability and mechanical properties of the neat EP were compared with that of asphalt. Laser scanning confocal microscopy observations revealed that AR particles disperse in the continuous epoxy phase with co-continuous phase-separated structures in EARs with 40 and 50 wt% AR. However, the phase inverts to continuous asphalt structures with dispersed spherical and co-continuous epoxy phase as AR concentration reaches 60 wt%. The addition of AR increases the viscosity of the neat EP. The thermal stability of the neat EP is improved with the incorporation of AR. The presence of AR decreases the tensile strength of the neat EP, while the elongation at break of the neat EP increases with the increase of AR concentration. The viscosity and mechanical properties of EAR with 50 wt% AR completely satisfy the technical requirement of hot-mix epoxy asphalt binder for steel bridge deck pavements.

Similar content being viewed by others

References

Cao Q (2015) Comprehensive utilization situation in 2014 & prediction in 2015 of China waste rubber industry. Paper presented at the 2015 China Rubber Conference, Guangzhou, 4 April

Liu S, Cao W, Fang J, Shang S (2009) Variance analysis and performance evaluation of different crumb rubber modified (CRM) asphalt. Constr Build Mater 23(7):2701–2708. doi:10.1016/j.conbuildmat.2008.12.009

Navarro FJ, Partal P, Martinez-Boza F, Gallegos C (2005) Influence of crumb rubber concentration on the rheological behavior of a crumb rubber modified bitumen. Energy Fuels 19(5):1984–1990. doi:10.1021/ef049699a

Lo Presti D (2013) Recycled tyre rubber modified bitumens for road asphalt mixtures: a literature review. Constr Build Mater 49:863–881. doi:10.1016/j.conbuildmat.2013.09.007

Frantzis P (2004) Crumb rubber–bitumen interactions: diffusion of bitumen into rubber. J Mater Civ Eng 16(4):387–390. doi:10.1061/(asce)0899-1561(2004)16:4(387)

Ge D, Yan K, You Z, Xu H (2016) Modification mechanism of asphalt binder with waste tire rubber and recycled polyethylene. Constr Build Mater 126:66–76. doi:10.1016/j.conbuildmat.2016.09.014

Fang CQ, Qiao XT, Yu RE, Yu X, Liu JJ, Yu J, Xia RH (2016) Influence of modification process parameters on the properties of crumb rubber/EVA modified asphalt. J Appl Polym Sci 33(27):13. doi:10.1002/app.43598

Yousefi Kebria D, Moafimadani SR, Goli Y (2015) Laboratory investigation of the effect of crumb rubber on the characteristics and rheological behaviour of asphalt binder. Road Mater Pavement Des 16(4):946–956. doi:10.1080/14680629.2015.1042015

Yu X (2014) Investigation of the rheological modification mechanism of warm-mix additives on crumb-rubber-modified asphalt. J Mater Civ Eng 26(2):312–319. doi:10.1061/(ASCE)MT.1943-5533.0000808

Williams RJJ, Rozenberg BA, Pascault J-P (1997) Reaction-induced phase separation in modified thermosetting polymers. In: Polymer analysis polymer physics. Springer, Berlin, pp 95–156. doi:10.1007/3-540-61218-1_7

Yin HY, Wang CS, Wang YT, Yuan ZR, Wang ZL, Xie HF, Cheng RS (2012) Cure reaction and morphology of epoxy asphalts. Polym Mater Sci Eng 28(11):30–33

Sun YF, Zhang YG, Xu K, Xie HF, Wang ZL, Cheng RS (2016) Comparative studies of domestic epoxy asphalt binders. J Nanjing Univ (Nat Sci) 52(2):213–220

Xie HF, Dai J, Liu CG, Yuan ZR, Wang ZL, Cheng RS (2009) Thermal analysis of epoxy asphalts. Polym Mater Sci Eng 25(11):115–117

Zhou X, Wu S, Liu G, Pan P (2016) Molecular simulations and experimental evaluation on the curing of epoxy bitumen. Mater Struct 49(1):241–247. doi:10.1617/s11527-014-0491-4

Kang Y, Chen Z, Jiao Z, Huang W (2010) Rubber-like thermosetting epoxy asphalt composites exhibiting atypical yielding behaviors. J Appl Polym Sci 116(3):1678–1685. doi:10.1002/app.31563

Sun Y, Zhang Y, Xu K, Xu W, Yu D, Zhu L, Xie H, Cheng R (2015) Thermal, mechanical properties, and low-temperature performance of fibrous nanoclay-reinforced epoxy asphalt composites and their concretes. J Appl Polym Sci 132(12):41694. doi:10.1002/app.41694

Xiao Y, van de Ven MFC, Molenaar AAA, Su Z, Zandvoort F (2011) Characteristics of two-component epoxy modified bitumen. Mater Struct 44(3):611–622. doi:10.1617/s11527-010-9652-2

Luo S, Lu Q, Qian Z (2015) Performance evaluation of epoxy modified open-graded porous asphalt concrete. Constr Build Mater 76:97–102. doi:10.1016/j.conbuildmat.2014.11.057

Zhang Y, Pan X, Sun Y, Xu W, Pan Y, Xie H, Cheng R (2014) Flame retardancy, thermal, and mechanical properties of mixed flame retardant modified epoxy asphalt binders. Constr Build Mater 68:62–67. doi:10.1016/j.conbuildmat.2014.06.028

Lu Q, Bors J (2015) Alternate uses of epoxy asphalt on bridge decks and roadways. Constr Build Mater 78:18–25. doi:10.1016/j.conbuildmat.2014.12.125

Qian Z, Wang R, Chen T (2014) Performance of epoxy asphalt and its mixture under different rubber powder dosages. J Build Mater 17(2):331–335

Yin H, Zhang Y, Sun Y, Xu W, Yu D, Xie H, Cheng R (2015) Performance of hot mix epoxy asphalt binder and its concrete. Mater Struct 48(11):3825–3835. doi:10.1617/s11527-014-0442-0

Liu Y, Zhang J, Chen R, Cai J, Xi Z, Xie H (2017) Ethylene vinyl acetate copolymer modified epoxy asphalt binders: phase separation evolution and mechanical properties. Constr Build Mater 137:55–65. doi:10.1016/j.conbuildmat.2017.01.081

Wang YT, Wang CS, Yin HY, Wang LL, Xie HF, Cheng RS (2012) Carboxyl-terminated butadiene-acrylonitrile-toughened epoxy/carboxyl-modified carbon nanotube nanocomposites: thermal and mechanical properties. Express Polym Lett 6(9):719–728. doi:10.3144/expresspolymlett.2012.77

Zhang JS, Wang YT, Wang XS, Ding GW, Pan YQ, Xie HF, Chen QM, Cheng RS (2014) Effects of amino-functionalized carbon nanotubes on the properties of amine-terminated butadiene–acrylonitrile rubber-toughened epoxy resins. J Appl Polym Sci 131(13):40472. doi:10.1002/App.40472

Kang Y, Song M, Pu L, Liu T (2015) Rheological behaviors of epoxy asphalt binder in comparison of base asphalt binder and SBS modified asphalt binder. Constr Build Mater 76:343–350. doi:10.1016/j.conbuildmat.2014.12.020

Sengoz B, Isikyakar G (2008) Analysis of styrene-butadiene-styrene polymer modified bitumen using fluorescent microscopy and conventional test methods. J Hazard Mater 150(2):424–432. doi:10.1016/j.jhazmat.2007.04.122

Xiang L, Cheng J, Que G (2009) Microstructure and performance of crumb rubber modified asphalt. Constr Build Mater 23(12):3586–3590. doi:10.1016/j.conbuildmat.2009.06.038

Jeong K-D, Lee S-J, Amirkhanian SN, Kim KW (2010) Interaction effects of crumb rubber modified asphalt binders. Constr Build Mater 24(5):824–831. doi:10.1016/j.conbuildmat.2009.10.024

Yamanaka K, Inoue T (1990) Phase separation mechanism of rubber-modified epoxy. J Mater Sci 25(1):241–245. doi:10.1007/bf00544214

Yamanaka K, Takagi Y, Inoue T (1989) Reaction-induced phase separation in rubber-modified epoxy resins. Polymer 30(10):1839–1844. doi:10.1016/0032-3861(89)90355-8

Heitzman M (1992) Design and construction of asphalt paving materials with crumb rubber modifier. Transp Res Rec 1339:1–8

Wang M, Yu Y, Wu X, Li S (2004) Polymerization induced phase separation in poly(ether imide)-modified epoxy resin cured with imidazole. Polymer 45(4):1253–1259. doi:10.1016/j.polymer.2003.12.037

Yu Y, Shen G, Liu Z (2015) Morphology of epoxy/thermoplastic blends. In: Parameswaranpillai J, Hameed N, Pionteck J, Woo EM (eds) Handbook of epoxy blends. Springer, Cham, pp 1–34. doi:10.1007/978-3-319-18158-5_18-1

Asphalt Institute (2003) Performance graded asphalt binder specification and testing superpave. Series No. 1 (SP-1). Asphalt Institute, Lexington, KY

Thodesen C, Shatanawi K, Amirkhanian S (2009) Effect of crumb rubber characteristics on crumb rubber modified (CRM) binder viscosity. Constr Build Mater 23(1):295–303. doi:10.1016/j.conbuildmat.2007.12.007

Lougheed TJ, Papagiannakis AT (1996) Viscosity characteristics of rubber-modified asphalts. J Mater Civ Eng 8(3):153–156. doi:10.1061/(asce)0899-1561(1996)8:3(153)

Qian Z, Chen C, Jiang C, Smit AdF (2013) Development of a lightweight epoxy asphalt mixture for bridge decks. Constr Build Mater 48:516–520. doi:10.1016/j.conbuildmat.2013.06.096

Zhao H, Cao Y, Sit SP, Lineberry Q, Pan W (2012) Thermal characteristics of bitumen pyrolysis. J Therm Anal Calorim 107(2):541–547. doi:10.1007/s10973-011-1590-x

Seidelt S, Müller-Hagedorn M, Bockhorn H (2006) Description of tire pyrolysis by thermal degradation behaviour of main components. J Anal Appl Pyrol 75(1):11–18. doi:10.1016/j.jaap.2005.03.002

Ghavibazoo A, Abdelrahman M (2013) Composition analysis of crumb rubber during interaction with asphalt and effect on properties of binder. Int J Pavement Eng 14(5):517–530. doi:10.1080/10298436.2012.721548

Liu YL, Wu CS, Chiu YS, Ho WH (2003) Preparation, thermal properties, and flame retardance of epoxy-silica hybrid resins. J Polym Sci Part A Polym Chem 41(15):2354–2367. doi:10.1002/pola.10778

Putman BJ, Amirkhanian SN (2010) Characterization of the interaction effect of crumb rubber modified binders using HP-GPC. J Mater Civ Eng 22(2):153–159. doi:10.1061/(asce)0899-1561(2010)22:2(153)

Nakanishi H, Takei S, Kasugai N (2005) Strength generation of epoxy asphalt mixture. In: 3rd China–Japan workshop on pavement technologies, Nanjing, China

Yin HY, Jin H, Wang CS, Sun YF, Yuan ZR, Xie HF, Wang ZL, Cheng RS (2014) Thermal, damping, and mechanical properties of thermosetting epoxy-modified asphalts. J Therm Anal Calorim 115(2):1073–1080. doi:10.1007/s10973-013-3449-9

Funding

This study was funded by the Program for Changjiang Scholars and Innovative Research Team in University (PCSIRT) and Priority Academic Program Development of Jiangsu Higher Education Institutions.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Liu, Y., Xi, Z., Cai, J. et al. Laboratory investigation of the properties of epoxy asphalt rubber (EAR). Mater Struct 50, 219 (2017). https://doi.org/10.1617/s11527-017-1089-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-017-1089-4