Abstract

The increase in drying shrinkage and decrease in tensile properties of concrete proportioned with recycled concrete aggregate (RCA) can result in a high risk of cracking under restrained conditions. However, the reduction of the modulus of elasticity of such concrete, can lead to greater stress relaxation and reduction in cracking potential. An experimental program was undertaken to evaluate the effect of using RCA at high substitution rates of 50 and 100% (by vol.) on the cracking potential under restrained conditions. Four different types of coarse RCA, two binder types, and water-to-cementitious materials ratio (w/cm) of 0.37 and 0.40 were considered in the study. Mechanical properties, drying shrinkage, and cracking potential using the ring test were investigated. Test results indicated no cracking up to 35 days in the case of the reference mixture and the concrete prepared with 50% RCA replacement. The 28-day stress rate of such mixtures were limited to 0.12 MPa/day. Depending on the RCA type, the incorporation of 100% coarse RCA in a binary system made with 0.40 w/cm increased the 35-day cracking potential to up to 74%, with values of stress rate ranging from 0.25 to 0.34 MPa/day. The mixtures proportioned with 100% RCA developed tensile creep coefficient of 0.34–0.78 at the time of cracking compared to 0.34–0.36 for the reference concrete at the same age. However, greater elastic concrete strain and lower tensile strength resulted in reduced time to cracking at 100% RCA replacement, which was 9.0–11.0 days.

Similar content being viewed by others

References

United States Environmental Protection Agency (2004) RCRA in focus: construction, demolition, and renovation. https://www.epa.gov/hwgenerators/resource-conservation-and-recovery-act-rcra-focus-hazardous-waste-generator-guidance

United States Environmental Protection Agency (2015) Advancing sustainable materials management: 2013 fact sheet. https://www.epa.gov/sites/production/files/2015-09/documents/2013_advncng_smm_fs.pdf

United States Environmental Protection Agency (2016) Advancing sustainable materials management: 2014 fact sheet. https://www.epa.gov/sites/production/files/2016-11/documents/2014_smmfactsheet_508.pdf

Gonzalez GP, Moo-Young HK (2004) Transportation applications of recycled concrete aggregate. FHWA state of the practice national review. Federal Highway Administration, Washington DC

NCHRP synthesis 435 (2013) Recycled materials and by-products in highway applications, volume 6, reclaimed asphalt pavement, recycled concrete aggregate, and construction demolition waste. Transportation Research Board, Washington D.C.

Monteiro P (2006) Concrete: microstructure, properties, and materials. McGraw-Hill Publishing, New York

Shah HR, Weiss J (2006) Quantifying shrinkage cracking in fiber reinforced concrete using the ring test. Mater Struct 39(9):887–899

Weiss WJ, Shah SP (2002) Restrained shrinkage cracking: the role of shrinkage reducing admixtures and specimen geometry. Mater Struct 35(2):85–91

Loser R, Leemann A (2009) Shrinkage and restrained shrinkage cracking of self-compacting concrete compared to conventionally vibrated concrete. Mater Struct 42(1):71–82

Hwang SD, Khayat KH (2010) Effect of mix design on restrained shrinkage of self-consolidating concrete. Mater Struct 43(3):367–380

Knaack AM, Kurama YC (2014) Behavior of reinforced concrete beams with recycled concrete coarse aggregates. J Struct Eng 141(3):B4014009

Fonseca N, De Brito J, Evangelista L (2011) The influence of curing conditions on the mechanical performance of concrete made with recycled concrete waste. Cement Concr Compos 33(6):637–643

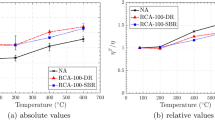

Vieira JPB, Correia JR, De Brito J (2011) Post-fire residual mechanical properties of concrete made with recycled concrete coarse aggregates. Cem Concr Res 41(5):533–541

Federal Highway Administration (FHWA) (2008) Recycled Concrete Aggregate, Federal Highway Administration National Review, FHWA, Washington, D.C. http://www.fhwa.dot.gov/pavement/recycling/rca.cfm

Henry M, Pardo G, Nishimura T, Kato Y (2011) Balancing durability and environmental impact in concrete combining low-grade recycled aggregates and mineral admixtures. Resour Conserv Recycl 55(11):1060–1069

Corinaldesi V (2010) Mechanical and elastic behaviour of concretes made of recycled-concrete coarse aggregates. Constr Build Mater 24(9):1616–1620

Kim SW, Yun HD (2013) Influence of recycled coarse aggregates on the bond behavior of deformed bars in concrete. Eng Struct 48:133–143

Yang KH, Chung HS, Ashour AF (2008) Influence of type and replacement level of recycled aggregates on concrete properties. ACI Mater J 105(3):289–296

Kang TH, Kim W, Kwak YK, Hong SG (2014) Flexural testing of reinforced concrete beams with recycled concrete aggregates. ACI Struct J 111(3):607

Adams MP, Fu T, Cabrera AG, Morales M, Ideker JH, Isgor OB (2016) Cracking susceptibility of concrete made with coarse recycled concrete aggregates. Constr Build Mater 102:802–810

ASTM C1581 (2016) Standard test method for determining age at cracking and induced tensile stress characteristics of mortar and concrete under restrained shrinkage. ASTM International, West Conshohocken, PA

Jeong H (2011) Processing and properties of recycled aggregate concrete. Master’s Thesis, University of Illinois at Urbana-Champaign

Khayat KH, Sadati S (2016) High-volume recycled materials for sustainable pavement construction. Final report prepared for Missouri Department of Transportation, (Report Number cmr 17-006)

Sadati S, Khayat KH (2016) Field performance of concrete pavement incorporating recycled concrete aggregate. Constr Build Mater 126:691–700

ASTM C143/C143M-15a (2015) Standard test method for slump of hydraulic-cement concrete. ASTM International, West Conshohocken, PA

ASTM C231/C231M-17a (2017) Standard test method for air content of freshly mixed concrete by the pressure method. ASTM International, West Conshohocken, PA

ASTM C39/C39M-17a (2017) Standard test method for compressive strength of cylindrical concrete specimens. ASTM International, West Conshohocken, PA

ASTM C469/C469M-14 (2014) Standard test method for static modulus of elasticity and Poisson’s ratio of concrete in compression. ASTM International, West Conshohocken, PA

ASTM C496/C496M-11 (2011) Standard test method for splitting tensile strength of cylindrical concrete specimens. ASTM International, West Conshohocken, PA

ASTM C157/C157M-08 (2008) Standard test method for length change of hardened hydraulic-cement mortar and concrete. ASTM International, West Conshohocken, PA

Silva RV, De Brito J, Dhir RK (2014) Properties and composition of recycled aggregates from construction and demolition waste suitable for concrete production. Constr Build Mater 65:201–217

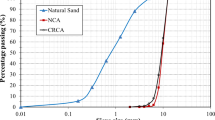

Omary S, Ghorbel E, Wardeh G (2016) Relationships between recycled concrete aggregates characteristics and recycled aggregates concretes properties. Constr Build Mater 108:163–174

Silva RV, de Brito J, Dhir RK (2016) Establishing a relationship between modulus of elasticity and compressive strength of recycled aggregate concrete. J Clean Prod 112:2171–2186

Jensen OM (ed) (2007) Report 41: internal curing of concrete-state-of-the-art report of RILEM Technical Committee 196-ICC, vol 41. RILEM publications

Gonzalez-Corominas A, Etxeberria M (2016) Effects of using recycled concrete aggregates on the shrinkage of high performance concrete. Constr Build Mater 115:32–41

Hwang SD, Khayat KH (2008) Effect of mixture composition on restrained shrinkage cracking of self-consolidating concrete used in repair. ACI Mater J 105(5):499

See HT, Attiogbe EK, Miltenberger MA (2003) Shrinkage cracking characteristics of concrete using ring specimens. ACI Mater J 100(3):239–245

Acknowledgements

The authors would like to acknowledge the financial support of the Missouri Department of Transportation (MoDOT) as well as the RE-CAST (Research on Concrete Applications for Sustainable Transportation) Tier-1 University Transportation Center (UTC) at Missouri University of Science and Technology (Missouri S&T).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Sadati, S., Khayat, K.H. Restrained shrinkage cracking of recycled aggregate concrete. Mater Struct 50, 206 (2017). https://doi.org/10.1617/s11527-017-1074-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-017-1074-y