Abstract

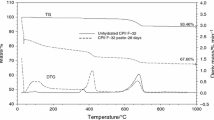

Portlandite and calcite are compounds of interest regarding different processes related to microstructural and durability issues of cementitious materials, such as carbonation, pozzolanic action, and hydration degree. The quantification of their contents in cementitious systems is thus frequently required. Thermogravimetry (TG) measures the change in mass of a material (as a function of time) over a temperature range using a predetermined heating rate. The TG method can be applied with certain success to estimate portlandite and calcite contents in the hydrated cement system, considering the temperature range at which each compound decomposes and releases water or carbon dioxide, respectively. However, a mature hydrated cement paste contains hydrated calcium silicate, portlandite and calcite phases. The quantification procedure is therefore complicated because of the concurrent interference among them. The tangential method over the TG signal or the integral method over the derivative TG curve is usually used to discount water loss from hydrated calcium silicates over the temperature range at which portlandite and calcite decompose. However, by the use of TG consistent underestimation of portlandite content in hydrated cementitious systems is still described in the literature. Potential causes for this underestimation are analysed in this paper, and a calibration procedure by means of an internal standard is proposed. Cement paste and aggregate samples are analysed. Differences between TG quantifications of these pure samples and those diluted with low contents of internal standards are compared with the added amounts of internal standard. In that way, a calibration method of the device is applied for correction of the actual portlandite and calcite contents in the samples. For this purpose, both analytic quality calcite and freshly prepared portlandite were used as internal standards. The results show that improved quantifications can be achieved with this calibration. Also, calcite seems to be more suitable as internal standard than portlandite as the best outcome was obtained for the first case.

Similar content being viewed by others

References

Ramachandran VS, Paroli RM, Beaudoin JJ, Delgado AH (2002) Handbook of thermal analysis of construction materials. Noyes Publications, Norwich, p 680

Lothenbach B, Durdziński P, De Weerdt K (2015) Thermogravimetric analysis. In: Scrivener K, Snellings R, Lothenbach B (eds) A practical guide to microstructural analysis of cementitious materials. CRC Press, Boca Raton, pp 177–211

Goto S, Suenaga K, Kado T, Fukuhara M (1995) Calcium silicate carbonation products. J Am Ceram Soc 78:2867–2872

Cole WF, Kroone B (1960) Carbon dioxide in hydrated portland cement. J Am Concr Inst 31:1275–1295

El-Jazairi B, Illston JM (1977) A simultaneous semi-isothermal method of thermogravimetry and derivative thermogravimetry, and its application to cement pastes. Cem Concr Res 7:247–257

Bukowsky JM, Berger RL (1979) Reactivity and strength development of CO2 activated non-hydraulic calcium silicates. Cem Concr Res 9:57–68

Thiery M, Villain G, Dangla P, Platret G (2007) Investigation of the carbonation front shape on cementitious materials: effects of the chemical kinetics. Cem Concr Res 37:1047–1058

Dweck J, Buchler PM, Vieira Coelho AC, Cartledge FK (2000) Hydration of a Portland cement blended with calcium carbonate. Thermochim Acta 346:105–113

Durdziński PT, Ben Haha M, Bernal SA, De Belie N, Gruyaert E, Lothenbach B, Provis JL, Schöler A, Stabler C, Tan Z, Villagrán-Zaccardi Y, Vollpracht A, Winnefeld F, Zając M, Scrivener KL (2017) Outcomes of the RILEM round robin on degree of reaction of slag and fly ash in blended cements. Mate Struct 50:135

De Belie N, Scrivener K, Lothenbach B, Gruyaert E, Skibsted J, Snellings R, Vollpracht A, Villagrán Y (2015) Determination of the degree of reaction of fly ash in blended cement pastes. In: Proceedings of the 14th international congress on the chemistry of cement, Beijing, p 12

De Schepper M (2014) Completely recyclable concrete for a more environment-friendly construction, Dissertation, Ghent University

Scrivener KL, Füllmann T, Gallucci E, Walenta G, Bermejo E (2004) Quantitative study of Portland cement hydration by X-ray diffraction/Rietveld analysis and independent methods. Cem Concr Res 34:1541–1547

Marsh BK (1984) Relationships between engineering properties and microstructural characteristics of hardened cement paste containing pulverized-fuel ash as a partial cement replacement, Dissertation, Hatfield Polytechnic and The Cement and Concrete Association

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Villagrán-Zaccardi, Y.A., Egüez-Alava, H., De Buysser, K. et al. Calibrated quantitative thermogravimetric analysis for the determination of portlandite and calcite content in hydrated cementitious systems. Mater Struct 50, 179 (2017). https://doi.org/10.1617/s11527-017-1046-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-017-1046-2