Abstract

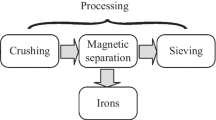

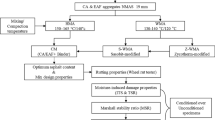

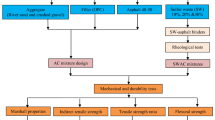

In order to improve microwave absorption which would be used for in situ repair of asphalt pavement, Fe3O4 was enriched on the surface of steel slag particles through an activated carbon-reduction method. The surface modified steel slags were then added into asphalt mixture to replace fine aggregates. The results showed that the microwave heating rate of modified steel slag was 84.3 °C/min. That was 34.1 and 65.1% higher than that of the control group of unmodified steel slag and fine basalt aggregate, respectively. Within the microwave frequency band of 2–4 GHz, the real part and imaginary part of the complex permittivity of the modified steel slag asphalt mixture (MSAM) increased by 6.4–12.5 and 4.7–13.7%, respectively, comparing those of the ordinary steel slag asphalt mixture (OSAM) and the ordinary basalt asphalt mixture (OBAM). Meanwhile, the real part and imaginary part of the complex permeability of the MSAM increased by 9.8–31.9% and over 6.2 times, respectively. Besides, the microwave heating rate of the MSAM increased by 44.2 and 82.1%, respectively, comparing those of the OSAM and the OBAM. Simulation indicated that after microwave heating for 15 min, the temperature within the OBAM ranged from 62.23 to 125.48 °C. Moreover, the temperature field distribution of numerical simulation was similar to that of the test results. Since microwave absorption was sharply enhanced in the asphalt pavement, it is expected to promote the microwave heating technology in the asphalt pavement.

Similar content being viewed by others

References

Terrel RL, Epps JA, Sorenson JB (1997) Hot-in-place recycling state-of-the-practice. J Assoc Asphalt Paving Technol 66:723–745

Koji S, Masuo I, Masanobu C (2007) Induction heating equipment for bridge deck asphalt pavement. JP2007146459

Harakawa K, Hayashida H, Takeuchi S, Tohyama K, Wakabayashi S (2008) Method for removing asphalt pavement, system for removing asphalt pavement, electromagnetic induction coil unit, device for removing asphalt pavement, and method for stripping asphalt pavement. EP2003248 A2

García A, Schlangen E, Van de Ven M, Liu Q (2012) A simple model to define induction heating in asphalt mastic. Constr Build Mater 31:38–46

Liu Q, Schlangen E, van de Ven M, García A (2011) Induction healing of asphalt mastic and porous asphalt concrete. Constr Build Mater 25:3746–3752

Liu Q, Schlangen E, van de Ven M (2012) Evaluation of the induction healing effect of porous asphalt concrete through four-point bending fatigue test. Constr Build Mater 29:403–409

Garcia A, Schlangen E, van de Ven M, Liu Q (2009) Electrical conductivity of asphalt mortar containing conductive fibers and fillers. Constr Build Mater 23:3175–3181

Liu Q, Schlangen E, van de Ven M, García A (2010) Induction heating of electrically conductive porous asphalt concrete. Constr Build Mater 24:1207–1213

Rudolf R, Mitschang P, Neitzel M (2000) Induction heating of continuous carbon-fibre reinforced thermoplastics. Compos A 31:1191–1202

Lu XH, Isacsson U (2002) Effect of ageing on bitumen chemistry and rheology. Constr Build Mater 16:15–22

García A, Schlangen E, van de Ven M, VanVliet D (2011) Induction heating of mastic containing conductive fibers and fillers. Mater Struct 44:499–508

García A (2012) Self-healing of open cracks in asphalt mastic. Fuel 93:264–272

Rudolf R, Mitschang P, Neitze M (2000) Induction heating of continuous carbon-fibre reinforced thermoplastics. Composites Part A ApplSciManuf 31:1191–1202

Metaxas AC (1996) Foundations of electro-heat: a unified approach. Wiley, New York

Ahmed TJ, Stavrov D, Bersee HEN, Beukers A (2006) Induction welding of thermoplastic composites-an overview. Composites Part A. Appl SciManuf 37:1638–1651

García A, Norambuena-Contreras J, Partl MN (2014) A parametric study on the influence of steel wool fibersin dense asphalt concrete. Mater Struct 47:1559–1571

Ahn j (2013) Microwave dielectric heating to disassemble a modifiedcementitious joint. Mater Struct 46:2077–2090

Al-Ohaly AA, Terrel RL (1988) Effect of microwave heating on adhesion and moisture damage of asphalt mixtures. Transportation research record 1171. Transportation Research Board, National Research Council, Washington, DC, pp 27–36

Benedetto A, Calvi A (2013) A pilot study on microwave heating for production and recycling of road pavement materials. Constr Build Mater 44:351–359

Kingman SW, Rowson NA (1998) Microwave treatment of minerals—a review. Miner Eng 11:1081–1087

Hopstock DM, Zanko LM (2005) Minnesota taconite as a microwave-absorbing road aggregate material for deicing and pothole patching applications. Retrieved from the University of Minnesota Digital Conservancy, http://hdl.handle.net/11299/974

Jaselskis EJ, Grigas J, Brilingas A (2003) Dielectric properties of asphalt pavement. J Mater Civ Eng 15(5):427–434

Long HW (2001) Asphaltic compositions and uses therefor. U.S. Patent: 6,193,793

Osborne TL, Hutcheson WR (1989) Asphalt compounds and method for asphalt reconditioning using microwave radiation. United States Patent: 4849020

Chinese National Specification (2011) Standard test methods of bitumen and bituminous mixtures for highway engineering (JTG E20-2011). China Communication Press, Beijing

Baba NH, Awang Z, Ghodgaonkar DK (2003) A free-space method for measurement of complex permittivity of silicon wafers at microwave frequencies. In: Asia-Pacific Conference on Applied Electromagnetics, 2003. APACE 2003, pp 119–123. IEEE

Miyakawa M, Yaguchi K, Ishii N, Saeki T, Kanai Y (2002) Accuracy improvement in permittivity measurement of construction materials by use of a model of the standing wave method in free space. In IEEE Int Symp on Electroman Comp, 2002. EMC 2002, vol 2, pp 809–814. IEEE

Zhu S, Shi J (2010) Research on temperature-dependent complex permittivity for large-size heterogeneous asphalt mixture. In: 2010 IEEE international conference on information and automation (ICIA), pp 2082–2086. IEEE

Acknowledgements

This work was financially supported by (1) the Fundamental Research Funds for the Central Universities and the Graduate Education Innovation Project of Jiangsu Province, China (KYLX15_0145) and (2) Nanjing Functional Pavements Technology co., LTD.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Miao, P., Liu, W. & Wang, S. Improving microwave absorption efficiency of asphalt mixture by enriching Fe3O4 on the surface of steel slag particles. Mater Struct 50, 134 (2017). https://doi.org/10.1617/s11527-017-1001-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-017-1001-2