Abstract

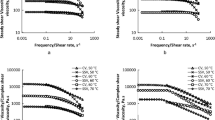

This paper is attempted to establish a practical shear rate for optimum compaction temperature determination of modified asphalt binders in asphalt mixture design. Viscosity of seven modified asphalt binders was measured, optimum compaction temperatures of eight asphalt mixtures were obtained and the shear rate range during roller compaction was estimated. Results showed that in the shear rate measuring range of commonly used Brookfield viscometer (0.3–25 s−1), viscosity characteristics at 25 s−1 showed the best similarity to viscosity characteristics during roller compaction in the shear rate range of 10–130 s−1. Also, viscosity at the shear rate of 25 s−1 exhibited the best correlation with the minimum compaction energy index of asphalt mixtures at optimum compaction temperatures. Based on the results above, 25 s−1 was suggested as the practical shear rate, providing a direct viscosity measurement for optimum compaction temperature determination of modified asphalt binders in asphalt mixture design.

Similar content being viewed by others

References

Sefidmazgi NR, Teymourpour P, Bahia HU (2013) Effect of particle mobility on aggregate structure formation in asphalt mixtures. Road Mater Pavement 14(Sup2):16–34

Asphalt Institute (1997) Mix design methods for asphalt concrete and other hot-mix types, 6th edn. Asphalt Institute, Lexington

Stuart KD (2002) Methodology for determining compaction temperatures for modified asphalt binders. Federal Highway Administration, McLean

Geng H, Clopotel CS, Bahia HU (2013) Effects of high modulus asphalt binders on performance of typical asphalt pavement structures. Constr Build Mater 44:207–213

Yildirim Y, Ideker J, Hazlett D (2006) Evaluation of viscosity values for mixing and compaction temperatures. J Mater Civil Eng 18(4):545–553

Lo Presti D, Fecarotti C, Clare AT, Airey G (2014) Toward more realistic viscosity measurements of tyre rubber–bitumen blends. Constr Build Mater 67:270–278

Bahia HU, Hanson D, Zeng M, Zhai H, Khatri M, Anderson R (2001) Characterization of modified asphalt binders in superpave mix design. Transportation Research Board

Yildirim Y, Kennedy TW (2003) Calculation of shear rate on asphalt binder in the Superpave gyratory compactor. Turk J Eng Environ Sci 27(6):375–381

Li N, Li T, Chen H, Zhang Z (2007) Mixing and compaction temperatures of modified asphalt mixture. China J Highw Transp 20(2):40–44

Li L, Geng H, Sun Y (2015) Simplified viscosity evaluating method of high viscosity asphalt binders. Mater Struct 48(7):2147–2156

ASTM Committee D08 (2015) Standard test method for viscosity determination of asphalt at elevated temperatures using a rotational viscometer. ASTM International, West Conshohocken. doi:10.1520/D4402_D4402M-15

Bahia HU, Friemel TP, Peterson PA, Russell JS, Poehnelt B (1998) Optimization of constructibility and resistance to traffic: a new design approach for HMA using the superpave compactor. J Assoc Asph Technol 67:189–232

Harman T, D’Angelo J, Bukowski J (2002) Superpave asphalt mixture design workshop workbook. US Department of Transportation, Federal Highway Administration

Sefidmazgi NR, Tashman L, Bahia H (2012) Internal structure characterization of asphalt mixtures for rutting performance using imaging analysis. Road Mater Pavement 13(Sup1):21–37

Chhabra RP (2010) Non-Newtonian fluids: an introduction. In: J Muralikrishnan, AP Deshpande, PB Sunil Kumar (eds) Rheology of complex fluids. Springer, New York, pp 3–34

Chang G, Xu Q, Rutledge J (2012) Intelligent compaction: Quality assurance for in-place density acceptance-asphalt IC demonstration in Maine. Federal Highway Administration, Washington, DC

Kandhal P, Chakraborty S (1996) Effect of asphalt film thickness on short and long-term aging of asphalt paving mixtures. Transp Res Rec 1535:83–90

Sengoz B, Agar E (2007) Effect of asphalt film thickness on the moisture sensitivity characteristics of hot-mix asphalt. Build Environ 42(10):3621–3628

Hand A, Epps A (2001) Impact of gradation relative to Superpave restricted zone on hot-mix asphalt performance. Transp Res Rec 1767:158–166

Kanitpong K, Sonthong S, Nam K, Martono W, Bahia H (2007) Laboratory study on warm mix asphalt additives. In: 86th annual meeting of the Transportation Research Board, Washington, DC

Acknowledgments

The authors would like to acknowledge Hussain U. Bahia, who provided the initial idea for this research. The authors would also like to acknowledge Xurong Ma, who conducted a part of viscosity test for this research.

Funding

This study was funded by Science and Technology Commission of Shanghai Municipality (grant number 12231205302 and grant number 16DZ1202000).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that we have no conflict of interest.

Rights and permissions

About this article

Cite this article

Geng, H., Li, L. A practical shear rate on modified asphalt binders for optimum compaction temperature determination in asphalt mixture design. Mater Struct 50, 61 (2017). https://doi.org/10.1617/s11527-016-0938-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-016-0938-x