Abstract

An effective method to strengthen existing reinforced concrete (RC) structures is to add a thin layer of ultra-high performance fiber reinforced cement-based composite (UHPFRC), with or without steel rebars, over the concrete slab to create a composite element. It was demonstrated by previous test series that this method increases rigidity, bending and shear strength of one-way RC members. This paper presents the results of punching tests on six composite slabs without transverse reinforcement. The parameters of the tests included the thickness of the UHPFRC layer and the amount of reinforcement in it. All slabs failed in punching mode with a drop in resistance after the maximum resistance was measured. For a layer of 50 mm of UHPFRC, the normalised resistance was at least 1.69 times greater than the normalised resistance of the RC reference slab. The layer of UHPFRC increased the rigidity of the slab and provided added shear resistance to the cracked RC section by out of plane bending. By doing so, it allowed more deformation to take place in the RC section before punching failure. This results in rotations and deflections at maximum resistance similar to what was observed for the reference RC slab.

Similar content being viewed by others

Abbreviations

- R:

-

Resistance

- U:

-

UHPFRC

- c:

-

Concrete

- i:

-

Steel or UHPFRC tensile reinforcement

- sc:

-

Top steel reinforcement layer in RC section

- sU:

-

Steel reinforcement in the R-UHPFRC layer

- A :

-

Area

- B :

-

Side length of slab specimen

- E cm,28 :

-

Average modulus of elasticity of concrete at 28 days

- E Um,28 :

-

Average modulus of elasticity of UHPFRC at 28 days

- V :

-

Punching shear force

- V csct :

-

Punching resistance of the concrete section calculated with CSCT

- V flex :

-

Estimated flexural resistance calculated with yield lines

- V res :

-

Residual shear resistance after punching failure

- b 0 :

-

Critical perimeter for punching shear set at d sc/2 from the column face

- c :

-

Side length of column

- d :

-

Flexural depth for a tensile reinforcement: distance from the bottom compression face of the slab to the centroid of the tensile reinforcement

- d eff :

-

Effective flexural depth calculated with the mechanical ratio of each tensile reinforcement

- d g :

-

Maximum diameter of aggregate

- d g0 :

-

Reference aggregate size set at 16 mm

- f :

-

Strength of a material

- f c :

-

Concrete compressive strength,

- f cm,28 :

-

Average concrete compressive strength at 28 days

- f sy :

-

Yield strength of steel reinforcement

- f su :

-

Maximum strength of steel reinforcement

- f Ute :

-

Maximum tensile elastic strength of UHPFRC

- f Utu :

-

Maximum tensile strength of UHPFRC

- h :

-

Height

- Δh :

-

Change in thickness of a slab

- Δl :

-

Change in distance between two points measured by a sensor

- w :

-

Measured deflection of the slab; crack opening

- Δw :

-

Shear deformation at the column face

- α c :

-

Minimum angle of the critical shear crack

- ε su :

-

Strain in steel reinforcement at maximum strength

- ε Utu :

-

Strain in UHPFRC at maximum tensile strength

- ψ :

-

Rotation

- ω :

-

Mechanical ratio of tensile reinforcement

- ω tot :

-

Total mechanical ratio of tensile reinforcement

References

Broms CE (2000) Elimination of flat plate punching failure mode. ACI Struct J 97(1):94–101

Habel K, Denarié E, Brühwiler E (2006) Structural response of elements combining ultrahigh-performance fiber-reinforced concretes and reinforced concrete. J Struct Eng 13(11):1793–1800

Denarié E, Brühwiler E (2011) Strain hardening of ultra-high performance fibre reinforced concrete: deformability versus strength optimization. Int J Restor Build Monum 12(6):397–410

Brühwiler E, Denarié E (2013) Rehabilitation and strengthening of concrete structures using ultra-high performance fiber reinforced concrete. Struct Eng Int 23(4):450–457

Oesterlee C (2010) Structural response of reinforced UHPFRC and RC composite members. Dissertation, EPFL, Lausanne

Habel K, Denarié E, Brühwiler E (2007) Experimental investigation of composite ultra-high-performance fiber reinforced concrete and conventional concrete members. ACI Struct J 104(1):93–101

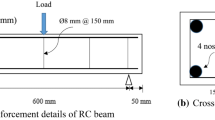

Noshiravani T, Brühwiler E (2013) Experimental investigation on R-UHPFRC–RC composite beams subjected to combined bending and shear. ACI Struct J 110(2):251–261

Bastien-Masse M (2014) Punching test on R-UHPFRC–RC composite slabs without shear reinforcement. Test report. MCS, EPFL, Lausanne

Guandalini S, Burdet OL, Muttoni A (2009) Punching tests of slabs with low reinforcement ratios. ACI Struct J 106(1):87–95

Muttoni A (2008) Punching strength of reinforced concrete slabs without transverse reinforcement. ACI Struct J 105(4):440–450

Theodorakopoulos DD, Swamy RN (2002) Ultimate punching shear strength analysis of slab-column connections. Cem Concr Compos 24:509–521

Menétrey Ph (2002) Synthesis of punching failure in reinforced concrete. Cem Concr Compos 24:497–507

Koppitz R, Kenel A, Keller T (2013) Punching shear of RC flat slabs—review of analytical models for new and strengthening of existing slabs. Eng Struct 52:123–130

Amsler M, Thoma K, Heinzmann D (2014) Punching slab strengthened with an additional concrete layer—test and recalculations. Beton- und Stahlbetonbau 109(6):394–402

Chen C-C, Li C-Y (2005) Punching shear strength of reinforced concrete slabs strengthened with glass fiber-reinforced polymer laminates. ACI Struct J 102(4):535–542

Esfahani MR, Kianoush MR, Moradi AR (2009) Punching shear strength of interior slab-column connections strengthened with carbon fiber reinforced polymer sheets. Eng Struct 31:1535–1542

Harajli MH, Soudki KA (2003) Shear strengthening of interior slab-column connections using fiber-reinforced polymer sheets. J Compos Constr 7(2):145–153

Sharaf MH, Soudki KA, Van Dusen M (2006) CFRP strengthening for punching shear of interior slab-column connections. J Compos Constr 10(5):410–418

Wuest J (2007) Comportement structural des bétons de fibres ultra performants en traction dans des éléments composés. Dissertation, EPFL, Lausanne

Guidotti R (2010) Poinçonnement des planchers-dalles avec colonnes superposées fortement sollicitées, Dissertation, EPFL, Lausanne

Clément T, Pinho Ramos A, Fernández Ruiz M, Muttoni A (2014) Influence of prestressing on the punching strength of post-tensionned slabs. Eng Struct 72:59–69

Lips S, Fernandez Ruiz M, Muttoni A (2012) Experimental investigation on punching strength and deformation capacity of shear-reinforced slabs. ACI Struct J 109(6):889–900

Rossi P (1997) High performance multimodal fiber reinforced cement composites (HPMFRCC): the LCPC experience. ACI Mater J 94(6):478–483

Rossi P, Arca A, Parant E, Fakhri P (2005) Bending and compressive behaviors of a new cement composite. Cem Concr Res 35:27–33

Fernández Ruiz M, Mirzaei Y, Muttoni A (2013) Post-punching behavior of flat slabs. ACI Struct J 110(5):801–811

Habibi F, Cook WD, Mitchell D (2014) Predicting post-punching shear response of slab-column connections. ACI Struct J 111(1):123–134

Acknowledgments

The authors would like to acknowledge Holcim Switzerland for donating the UHPFRC premix S3-13 used to fabricate slab series PBM.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bastien-Masse, M., Brühwiler, E. Experimental investigation on punching resistance of R-UHPFRC–RC composite slabs. Mater Struct 49, 1573–1590 (2016). https://doi.org/10.1617/s11527-015-0596-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1617/s11527-015-0596-4