Abstract

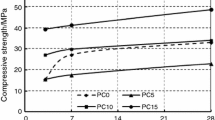

In this work, the effect of different contents of Portland cement (PC) on the heat of hydration, pH value, compressive strength and drying shrinkage of 1 % Na2O equivalent of Na2SO4 activated ground granulated blast-furnace slag (hereafter referred as slag) has been investigated and compared to slag activated with other common activators. Slag was partially replaced with PC at levels of 0, 5, 10 and 15 %, by weight. The various decomposition phases formed were indentified using X-ray diffraction, thermogravimetric analysis and scanning electron microscopy. The results showed an increase in the heat of hydration and compressive strength with the inclusion of 10 and 15 % PC. On the other hand, 5 % PC reduced the compressive strength. The pH value increased with increasing PC content, whilst drying shrinkage decreased with increasing PC content.

Similar content being viewed by others

References

Komnitsas KA (2011) Potential of geopolymer technology towards green buildings and sustainable cities. Proc Eng 21:1023–1032

Fernando P-T, Said J (2011) Resistance to acid attack, abrasion and leaching behavior of alkali-activated mine waste binders. Mater Struct 44:487–498

Rashad AM (2013) Alkali-activated metakaolin: a short guide for Civil Engineer—an overview. Constr Build Mater 41:751–765

CEMBUREAU (2009) Activity report 2008. CEMBUREAU, Brussels

Worrell E, Price I, Martin N, Hendriks C, Meida LO (2001) Carbon dioxide emissions from the global cement industry. Annu Rev Energy Env 26:303–329

Shi C, Qian J (2000) High performance cementing materials from industrial slags- a review. Resour Conserv Recycl 29:195–207

Rashad AM, Zeedan SR (2011) The effect of activator concentration on the residual strength of alkali-activated fly ash pastes subjected to thermal load. Constr Build Mater 25:3098–3107

Rashad AM (2013) A comprehensive overview about the influence of different additive on the properties of alkali-activated slag—a guide for Civil Engineer. Constr Build Mater 47:29–55

Rashad AM (2013) Properties of alkali-activated fly ash concrete blended with slag. Iran J Mater Sci Eng 10(1):57–64

Rashad AM (2014) A comprehensive overview about the influence of different admixtures and additives on the properties of alkali-activated fly ash. Mater Des 53:1005–1025

Yang K-H, Song J-K, Song K-I (2013) Assessment of CO2 reduction of alkali-activated concrete. J Clean Prod 39:265–272

Rashad AM, Khalil MH (2013) A preliminary study of alkali-activated slag blended with silica fume under the effect of thermal loads and thermal shock cycles. Constr Build Mater 40:522–532

Rashad AM, Zeedan SR, Hassan AH (2012) A preliminary study of autoclaved alkali-activated slag blended with quartz powder. Constr Build Mater 33:70–77

Chi M, Huang R (2013) Binding mechanism and properties of alkali-activated fly ash/slag mortars. Constr Build Mater 40:291–298

Aydın S (2013) A ternary optimization of mineral additives of alkali activated cement mortars. Constr Build Mater 43:131–138

Rashad AM, Bai Y, Basheer PAM, Milestone NB, Collier NC (2013) Hydration and properties of sodium sulfate activated slag. Cem Concr Compos 37:20–29

Wu X, Jiang W, Roy DM (1990) Early activation and properties of slag cement. Cem Concr Res 20:961–974

Rashad AM, Bai Y, Basheer PAM, Collier NC, Milestone NB (2012) Chemical and mechanical stability of sodium sulfate activated slag after exposure to elevated temperature. Cem Concr Res 42:333–343

Douglas E, Brandstetr J (1990) A preliminary study on the alkali activation of ground granulated blast-furnace slag. Cem Concr Res 20:746–756

Wang S-D, Scrivener KL, Pratt PL (1994) Factors affecting the strength of alkali-activated slag. Cem Concr Res 24(6):1033–1043

Puertas F (1995) Alkali-activated slag cements: present and future. Mater Constr 45(239):53–64 (Spanish)

Pu XC, Gan CC, Wang SD, Yang CH (1988) Research reports of an alkali-activated slag cement and concrete. Chongqing Institute of Architecture and Engineering, Chongqing

Langan BW, Weng K, Ward MA (2002) Effect of silica fume and fly ash on heat of hydration of Portland cement. Cem Concr Res 32:1045–1051

Poppe A-M, De Schutter G (2005) Cement hydration in the presence of high filler contents. Cem Concr Res 35:2290–2299

Snelson DG, Wild S, O’Farrell M (2008) Heat of hydration of Portland cement–metakoalin–fly ash (PC–MK–PFA) blends. Cem Concr Res 38:832–840

Robeyst N, Grosse CU, De Belie N (2009) Measuring the change in ultrasonic p-wave energy transmitted in fresh mortar with additives to monitor the setting. Cem Concr Res 39:868–875

Voigt T, Shah SP (2004) Properties of early-age Portland cement mortar monitored with shear wave reflection method. ACI Mater J 101:473–482

Wang K, Fe Z, Grove J, Ruiz MJ, Rasmussen R, Ferragut T (2007) Developing a simple and rapid test for monitoring the heat evolution of concrete mixtures for both laboratory and field applications. Center for Transportation Research and Education, Lowa State University, Ames

Mehta PK (1986) Concrete, structure, properties, and materials. Prentice-Hall, Upper Saddle River

Neville AM, Brooks JJ (1987) Concrete technology. Longman Group, New York

Song S, Sohn D, Jennings HM, Mason TO (2000) Hydration of alkali-activated ground granulated blast furnace slag. J Mater Sci 35:249–257

Gebhart RF (1995) Survey of North American Portland cement. Cem Aggreg 17:175–189

Song S, Jennings HM (1999) Pore solution chemistry of alkali-activated ground granulated blast-furnace slag. Cem Concr Res 29:159–170

Fernández-Jimènez A, Puertas F (2003) Effect of activator mix on the hydration and strength behavior of alkali-activated slag cement. Adv Cem Res 15(3):129–136

Zhou H, Wu X, Xu Z, Tang M (1993) Kinetic study on hydration of alkali activated slag. Cem Concr Res 23(6):1253–1258

Chang J (2003) A study on the setting characteristics of sodium silicate activated slag pastes. Cem Concr Res 33(7):1005–1011

Bakharev T, Sanjayan JG, Cheng Y-B (1999) Alkali activated of Australian slag cements. Cem Concr Res 29:113–120

Bilim C, Atiş CD (2012) Alkali activation of mortars containing different replacement levels of ground granulated blast furnace slag. Constr Build Mater 28:708–712

Talling B, Brandstetr J (1989) Present state and future of alkali-activated slag concretes. In: 3rd international conference on fly-ash, silica fume, slag and natural pozzolanas in concrete. 2(114–174):1519–1546

Fu-Sheng W, Rui-Lian S, Ying-Jing C (2005) Study on modification of the high-strength slag cement material. Cem Concr Res 35:1344–1348

Villain G, Thiery M, Platret G (2007) Measurement methods of carbonation profile in concrete: thermogravimetry, chemical analysis and gammadensimetry. Cem Concr Res 37:1182–1192

Reis PNB, Ferreira JAM, Antunes FV, Costa JDM (2008) Flexural behavior of hybrid laminated composites with natural fibers: coupling agent effect. J Degrad Stab 93:1170–1175

Taylor HFW (1997) Cement chemistry. Thomas Telford, London

Greene KT (1960) Early hydrations of Portland cement. In: Proceedings of the fourth international symposium on chemistry of cements, Washington, pp 359–458

Wang SD (1995) Alkaline activation of slag. PhD Thesis, University of London, London

Weiguo S, Yiheng W, Tao Z, Mingkai Z, Jiasheng L, Xiaoyu C (2011) Magnesia modification of alkali-activated slag fly ash cement. J Wuhan Univ Technol 26:121–125

Krizan D, Zivanovic B (2002) Effects of dosage and modulus of water glass on early hydration of alkali-slag cements. Cem Concr Res 32:1181–1188

Palacios M, Puertas F (2007) Effect of shrinkage-reducing admixtures on the properties of alkali-activated slag mortars and pastes. Cem Concr Res 37(691):702

Atiş CD, Bilim C, Çelik Ö, Karahan O (2009) Influence of activator on the strength and drying shrinkage of alkai-activated slag mortar. Constr Build Mater 23:548–555

Collins F, Sanjayan JG (2001) Microcracking and strength development of alkali-activated slag concrete. Cem Concr Compos 23(4–5):345–352

Jimenez AF, Puertas F (2001) Setting of alkali-activated slag cements influence of activator nature. Adv Cem Res 13(3):115–121

Krizan D, Zivanovic B (2002) Effect of dosage and modulus of water glass on early hydration of alkali-slag cements. Cem Concr Res 32(8):1181–1188

Shi C, Day RL, Wu X, Tang M (1992) Comparison of microstructure and performance of alkai-slag and Portland cement pastes. In: 9th international congress on chemistry of cements, New Delhi. 3:482–488

Wang SD, Pu X-C, Scrivener K, Pratt PL (1995) Alkali-activated slag cement and concrete: a review of properties and problems. Adv Cem Res 7(27):93–107

Kutti T (1992) Hydration products of alkali activated slag. In: 9th International congress on chemistry of cements, New Delhi 3:468–474

Acknowledgments

A.M. Rashad was sponsored by Egyptian government for his academic visit to Queen’s University Belfast (QUB), U.K. The slag used in this research was supplied by Hanson Cement. Prof. PAM Basheer, Dr. Yun Bai and the facilities provided by the School of Planning, Architecture and Civil Engineering at Queen’s University Belfast are also gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rashad, A.M. An exploratory study on sodium sulfate activated slag modified with Portland cement. Mater Struct 48, 4085–4095 (2015). https://doi.org/10.1617/s11527-014-0468-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1617/s11527-014-0468-3