Abstract

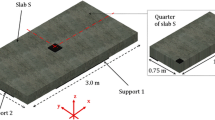

The analysis of tests conducted on small-scale slabs at ambient and elevated temperatures is presented in this paper. The slabs were produced from a new type of concrete containing different levels of glass sand and basalt fibre. Two methods were used for this purpose: a simplified method developed previously and a finite element method, using the software package ABAQUS. For the slabs at ambient temperature, the results showed a good correlation for the load–displacement relationship between the test and the two models up to the failure loads. For the slabs at elevated temperature, the ABAQUS model gave a reasonable prediction for the temperature–displacement relationship while the simplified method gave a conservative prediction for the maximum allowable vertical displacement. As a result, the simplified method underestimated the temperature at which the reinforcement fracture occurs for this type of concrete slab, incorporating glass sand and basalt fibres. Further work is required to remove this conservatism from the simplified design method for this type of concrete.

Similar content being viewed by others

Abbreviations

- e :

-

Enhancement due to membrane action

- f cu :

-

Compressive cube strength of concrete

- P :

-

Theoretical yield line load

- P test :

-

Maximum sustained load from the test

- T Bot :

-

Temperature at the bottom of the slab

- T Mesh :

-

Temperature of the slab reinforcement

- T Pred :

-

Predicted temperature

- T Test :

-

Test temperature

- T top :

-

Temperature at the top of the slab

- ΔABAQUS :

-

Maximum displacement predicted by ABAQUS

- ΔFire :

-

Maximum vertical displacement at failure for elevated temperature tests

- Δmax :

-

Maximum displacement

- ΔTest :

-

Maximum displacement recorded in the test

- ρ :

-

Reinforcement ratio

References

Bailey C, Lennon T, Moore D (1999) The behaviour of full-scale steel-framed buildings subjected to compartment fires. Struct Eng 77:15–21

Bailey C, Moore D (2000) The structural behaviour of steel frames with composite floorslabs subject to fire. Pt. 2: design. Struct Eng 78:19–27

Lange DJ (2009) Risk and performance based fire safety design of steel and composite structures, PhD thesis, The University of Edinburgh

Cameron N, Usmani A (2005) New design method to determine the membrane capacity of laterally restrained composite floor slabs in fire. Part 1: theory and method. Struct Eng 83:28–33

Wood R (1961) Plastic and elastic design of slabs and plates: with particular reference to reinforced concrete floor slabs. Thames and Hudson, London

Taylor R (1965) A note on a possible basis for a new method of ultimate load design of reinforced concrete slabs. Mag Concr Res 17(53):183–186

Sawczuk A, Winnicki L (1965) Plastic behavior of simply supported reinforced concrete plates at moderately large deflections. Int J Solids Struct 1(1):97–110

Hayes B (1968) Allowing for membrane action in the plastic analysis of rectangular reinforced concrete slabs. Mag Concr Res 20(65):205–212

Bailey C, White D, Moore D (2000) The tensile membrane action of unrestrained composite slabs simulated under fire conditions. Eng Struct 22(12):1583–1595

Bailey C (2001) Membrane action of unrestrained lightly reinforced concrete slabs at large displacements. Eng Struct 23(5):470–483

Bailey CG (2003) Efficient arrangement of reinforcement for membrane behaviour of composite floor slabs in fire conditions. J Constr Steel Res 59(7):931–949

Bailey CG, Toh WS (2007) Behaviour of concrete floor slabs at ambient and elevated temperatures. Fire Saf J 42(6–7):425–436

Newman GM, Robinson JT, Bailey CG (2000) Fire safe design: a new approach to multi-story steel-framed buildings, SCI publication, London, p 288

Bailey CG (2001) Steel structures supporting composite floor slabs: design for fire. BRE digest 462, The Building Research Establishment, Watford

Newman GM, Robinson JT, Bailey CG (2006) Fire safe design: a new approach to multi-story steel-framed buildings, 2nd edn. SCI publication, Ascot, p 288

Borhan TM (2012) Properties of glass concrete reinforced with short basalt fibre. Mater Des 42:265–271

Sim J, Park C, Moon D (2005) Characteristics of basalt fiber as a strengthening material for concrete structures. Compos B Eng 36(6–7):504–512

Borhan TM, Bailey CG (2013) Structural behaviour of basalt fibre reinforced glass concrete slabs. Mater Struct. doi:10.1617/s11527-013-0046-0

Bailey CG, Toh WS (2007) Small-scale concrete slab tests at ambient and elevated temperatures. Eng Struct 29(10):2775–2791

BSEN1993:1-2 (2005) Eurocode 3: design of steel structures. Part 1-2. General rules. Structural fire engineering, British Standards, London

BSEN1992:1-2 (2004) Eurocode 2, design of concrete structures. General rules—structural fire design. British Standards, London

CEB-FIP Model Code 1990 (1993) Thomas Telford Ltd., London

Hordijk D (1991) Local approach to fatigue of concrete, PhD thesis, Delft University of Technology

Malm R (2006) Shear cracks in concrete structures subjected to in-plane stresses. Trita-BKN. Bulletin 88

Lubliner JJ, Oliver SO, Onate E (1989) A plastic-damage model for concrete. Int J Solids Struct 25(3):229–326

Chan BM (2008) Membrane action of concrete floor slabs at ambient and elevated temperatures. University of Manchester, Manchester, p 286

Takeuchi M, Hiramoto M, Kumagai N, Yamazaki N, Kodaira A, Sugiyama K (1993) Material properties of concrete and steel bars at elevated temperatures. In: Proceedings of Structural Mechanics in Reactor Technology (SMiRT 12), pp 133–138

Chan YN, Peng GF, Anson M (1999) Residual strength and pore structure of high-strength concrete and normal strength concrete after exposure to high temperatures. Cem Concr Compos 21(1):23–27

Dias W, Khoury G, Sullivan P (1990) Mechanical properties of hardened cement paste exposed to temperatures up to 700 C (1292 F). ACI Mater J 87(2):160–166

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Borhan, T.M., Bailey, C.G. Modelling basalt fibre reinforced glass concrete slabs at ambient and elevated temperatures. Mater Struct 47, 999–1009 (2014). https://doi.org/10.1617/s11527-013-0109-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1617/s11527-013-0109-2