Abstract

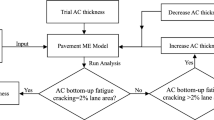

The variability of resilient modulus (M R) of unbound materials and subgrade due to laboratory test conditions affect pavement performance and designs. The performance-based mechanistic-empirical pavement design guide (MEPDG) is gaining more popularity in recent years for pavement design use. However, limited research efforts have quantitatively studied M R effects based on ME models. This research targets to evaluate the influences of M R variability on pavement performance and designs based on the MEPDG performance models. With a normal-distribution of M R seed values, pavement responses were computed with a layer-elastic analysis model, pavement performance was then predicted using MEPDG models, and design variability was studied via Monte Carlo simulation. Results indicate that the relationship between layer design thickness and M R varies from almost linear to nonlinear, which is highly dependent on the pavement structure and material properties. For the evaluated specific pavement structure and range of M R values, the least susceptible is the HMA design thickness as a function of M R under fatigue with a design Coefficient of Variance (CV) of 7.51 %, while the most susceptible is the base design thickness as a function of M R also under fatigue with a CV of 54.32 %. The combined effect of both rut depth and fatigue life considering the variability of both base and subgrade results in a design CV of 22.58 % for asphalt layer and 26.08 % for base layer. When using a weaker base layer or a thinner HMA layer, the modeled thickness design CV has changed −4.19 to 1.14 %.

Similar content being viewed by others

References

Rahim M (2005) Subgrade soil index properties to estimate resilient modulus for pavement design. Int J Pavement Eng 6(3):163–169

Mohammed EB, Hani TH (2006) Evaluation of resilient modulus model parameters for mechanistic-empirical pavement design. Transp Res Rec CODEN TRREDM 1967:89–100

Loulizi A, Flintsch GW, Al-Qadi IL, Mokarem D (2006) Comparing resilient modulus and dynamic modulus of hot-mix asphalt as material properties for flexible pavement design. J Transp Res Board 1970:161–170

Araya AA, Huurman M, Molenaar AAA, Houben LJM (2011) Investigation of the resilient behavior of granular base materials with simple test apparatus. Mater Struct. doi:10.1617/s11527-011-9790-1

Tian P, Zaman MM, Laguros JG (1998) Variation of resilient modulus of aggregate base and its influence on pavement performance. J Test Eval 26(4):329–335

Baus RL, Fogg JA (1989) AASHTO flexible pavement design equation study. J Transp Eng 115(5):559–564

Gharaybeh FA, AI-Massaeid HR, Obaidat MT (1998) Parametric sensitivity study of the AASHTO flexible pavement design equation. J Inst Eng (India) 78:175–179

Barksdale RD, Alba J, Khosla NP, Lambe PC, Rahman MS (1997) Laboratory determination of resilient modulus for flexible pavement design. NCHRP Web Doc 14 (project 1-28), Washington

Applied Research Associate, Inc (2004) Guide for mechanistic-empirical design of new and rehabilitated pavement structures. NCHRP 1-37A Final Report. http://onlinepubs.trb.org/onlinepubs/archive/mepdg/guide.htm

Suh YC, Cho NH, Mun S (2011) Development f mechanistic-empirical design next term method for an asphalt previous term pavement next term rutting model using APT. Constr Build Mater 25:1685–1690

Schwartz CW (2009) Influence of unbound materials on flexible pavement performance: a comparison of the AASHTO and MEPDG methods. In: Eighth international conference on the bearing capacity of roads, railways, and airfields, Urbana-Champaign, IL, pp 951–959

Transportation Research Circular No. E-C155 (2011) Sensitivity Analyses for Flexible Pavement Design with the Mechanistic-Empirical Pavement Design Guide. Transportation Research Board, National Academies

Li R, Schwartz CW, Kim S, Ceylan H (2012) Local sensitivity of mechanistic-empirical flexible pavement performance predictions to unbound material property inputs. In: GeoCongress 2012, Oakland, pp 1495–1504

Schwartz CW, Li R, Kim SH, Ceylan H (2012) Sensitivity evaluation of MEPDG performance prediction. NCHRP 01-47 final report, Washington. http://apps.trb.org/cmsfeed/TRBNetProjectDisplay.asp?ProjectID=2487

Acknowledgments

Authors would like to acknowledge the support from the Federal Highway Administration and Transportation Pooled Funding project, “Surface enhancements and pavement design data collection-DTFH61-08-D-00026”.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xu, Q., Ruiz, J.M., Moravec, M. et al. Simulation of unbound material resilient modulus effects on mechanistic-empirical pavement designs. Mater Struct 46, 1089–1100 (2013). https://doi.org/10.1617/s11527-012-9955-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1617/s11527-012-9955-6