Abstract

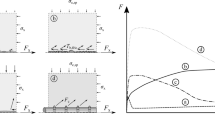

An important parameter for dimensioning of Textile Reinforced Concrete (TRC) structures and structural elements is the tensile load-bearing capacity of the composite. Respective values are usually derived from uniaxial tensile tests with overcritically reinforced TRC specimens. In this paper, influences from specimen geometry, e.g. plane and waisted specimens, and load application design, e.g. stiff glued steel plates or soft clamping constructions are investigated. Therefore, experimental results regarding the load-bearing capacity of the composite are statistically evaluated. The experimental observations are supported by results of numerical simulations with a one-dimensional model based on the Finite Element Method. These simulations provide stress distributions in concrete and reinforcing fibres as well as the tensile load-bearing capacity. Based on these results existing test setups for the derivation of the load-bearing capacity of the composite for dimensioning are assessed. As a result, plane plate specimens with a load application by means of friction is recommended for experimental determination.

Similar content being viewed by others

References

Abdkader A (2004) Charakterisierung und Modellierung der Eigenschaften von AR-Glasfilamentgarnen für die Betonbewehrung. Dissertation, TU Dresden

Bösche A, Jesse F, Ortlepp R, Weiland S, Curbach M (2008) Textile Reinforced Concrete for flexural strengthening of RC-structures—Part 1: Structural behavior and design model. In: Aldea CM (ed) ACI SP-251 Design & applications of textile-reinforced concrete. ACI, Farmington Hills, pp 19–40

Brockmann T, Raupach M (2002) Durability investigations on Textile Reinforced Concrete. In: Proceedings of the 9th international conference on durability of building materials and components (CSIRO2002), Brisbane, Australia, paper no. 111

Bruckermann O (2007) Zur Modellierung des Zugtragverhaltens von textilbewehrtem Beton. Dissertation, RWTH Aachen

Brückner A, Ortlepp R, Curbach M (2006) Textile Reinforced Concrete for strengthening in bending and shear. Mater Struct 39(8):741–748. doi:10.1617/s11527-005-9027-2

Brückner A, Ortlepp R, Curbach M (2008) Anchoring of shear strengthening for T-beams made of Textile Reinforced Concrete (TRC). Mater Struct 41(2):407–418. doi:10.1617/s11527-007-9254-9

Chudoba R, Vořechovský M, Konrad M (2006) Stochastic modeling of multi-filament yarns. I. Random properties within the cross-section and size effect. Int J Solids Struct 43(3–4):413–434. doi:10.1016/j.ijsolstr.2005.06.063

Curbach M, Schicktanz K, Jesse F, Hartig J (2006) Stochastische Eigenschaften der Zugfestigkeit freier und zementös eingebetteter Filamentbündel aus AR-Glas. In: Ruge P, Graf W (eds) 10. Dresdner Baustatik-Seminar, Neue Bauweisen—Trends in Statik und Dynamik. TU Dresden, Dresden, pp 91–100

Curbach M, Weiland S, Michler H (2008) Textile Reinforced Concrete—the bridge between the textile industry and the construction sector. Text J 125(4):58–69

Daniels HE (1945) The statistical theory of the strength of bundles of threads. I. Proc R Soc Lond A183:405–435

Dugas M, Weise S, Curbach M, Hempel R, Offermann P, Franzke G (1998) Force-deformation behaviour of tensile-loaded specimens made of Textile Reinforced Concrete. In: Techtextil symposium 1998, Lyon, pp 143–152

Gao SL, Mäder E, Plonka R (2004) Coatings for glass fibers in a cementitious matrix. Acta Mater 52(16):4745–4755. doi:10.1016/j.actamat.2004.06.028

Gao SL, Mäder E, Plonka R (2007) Nanostructured coatings of glass fibers: improvement of alkali resistance and mechanical properties. Acta Mater 55(3):1043–1052. doi:10.1016/j.actamat.2006.09.020

Hartig J, Häußler-Combe U, Schicktanz K (2008) Influence of bond properties on the tensile behaviour of Textile Reinforced Concrete. Cem Concr Compos 30(10):898–906. doi:10.1016/j.cemconcomp.2008.08.004

Hartig J, Jesse F, Häußler-Combe U (2010) Evaluation of experimental setups for determining the tensile strength of Textile Reinforced Concrete. In: Brameshuber W (ed) 2nd ICTRC—Textile Reinforced Concrete: proceedings of the international RILEM conference on material science (MatSci), vol 1. RILEM Publications S.A.R.L., Bagneux, pp 117–127

Hausding J, Lorenz E, Ortlepp R, Lundahl A, Cherif C (2011) Application of stitch-bonded multi-plies made by using the extended warp knitting process: reinforcements with symmetrical layer arrangement for concrete. J Text Inst. doi:10.1080/00405000.2010.515729

Hegger J, Will N, Bruckermann O, Voss S (2006) Load-bearing behaviour and simulation of Textile Reinforced Concrete. Mater Struct 39:765–776. doi:10.1617/s11527-005-9039-y

Jesse F (2004) Load bearing behaviour of filament yarns in a cementitious matrix. Dissertation, TU Dresden (in German)

Köckritz U (2007) In-situ Polymerbeschichtung zur Strukturstabilisierung offener nähgewirkter Gelege. Dissertation, TU Dresden

Konrad M, Chudoba R (2009) Tensile behavior of cementitious composite reinforced with epoxy impregnated multifilament yarns. Int J Multiscale Comput Eng 7(2):115–133. doi:10.1615/IntJMultCompEng.v7.i2.40

Lorenz E, Ortlepp R, Hausding J, Cherif C (2011) Effizienzsteigerung von Textilbeton durch Einsatz textiler Bewehrungen nach dem erweiterten Nähwirkverfahren. Beton Stahlbetonbau 106(1):21–30. doi:10.1002/best.201000072

Molter M (2005) Zum Tragverhalten von textilbewehrtem Beton. Dissertation, RWTH Aachen

Orlowsky J, Raupach M (2006) Modelling the loss in strength of AR-glass fibres in textile-reinforced concrete. Mater Struct 39:635–643

Brameshuber W et al (2010) Uniaxial tensile test—test method to determine the load bearing behavior of tensile specimens made of textile reinforced concrete (Proposal for a recommendation by RILEM TC 232-TDT to be published in Materials and Structures)

Vořechovský M (2010) Incorporation of statistical length scale into Weibull strength theory for composites. Compos Struct 92(9):2027–2034. doi:10.1016/j.compstruct.2009.11.025

Vořechovský M, Chudoba R (2006) Stochastic modeling of multi-filament yarns. II. Random properties over the length and size effect. Int J Solids Struct 43(3–4):435–458. doi:10.1016/j.ijsolstr.2005.06.062

Weibull W (1951) A statistical distribution function of wide applicability. J Appl Mech 18:293–297

Weiland S, Ortlepp R, Hauptenbuchner B, Curbach M (2008) Textile Reinforced Concrete for flexural strengthening of RC-structures—Part 2: Application on a concrete shell. In: Aldea CM (eds) ACI SP-251 Design & applications of textile-reinforced concrete. ACI, Farmington Hills, pp 41–58

Acknowledgments

The authors gratefully acknowledge the financial support of this research from Deutsche Forschungsgemeinschaft DFG (German Research Foundation) within the Sonderforschungsbereich 528 (Collaborative Research Center) “Textile Reinforcement for Structural Strengthening and Retrofitting” at Technische Universität Dresden, Germany.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hartig, J., Jesse, F., Schicktanz, K. et al. Influence of experimental setups on the apparent uniaxial tensile load-bearing capacity of Textile Reinforced Concrete specimens. Mater Struct 45, 433–446 (2012). https://doi.org/10.1617/s11527-011-9775-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1617/s11527-011-9775-0