Abstract

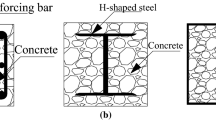

The stress state of thick-walled cylinder will be improved when it is composed of multi-layer concrete with different Young’s modulus of elasticity. The optimum design method for double-layer concrete cylinders is discussed in this paper. When the modulus of the inner-layer concrete is less than the outer one, the stress concentration on the cylinder inner surface will be relieved and the maximum tangential stress may be transferred from the inner surface of inner-layer to the inner surface of outer-layer, where is in triaxial stress state. The elastic limit bearing capacity of double-layer concrete cylinder will be improved due to the high compressive strength of concrete in triaxial stress state. Compared with the conditional single-layer thick-walled cylinder, the thickness of the double-layer cylinder can be reduced evidently. On the basis of stress solution of double-layer cylinder and by using the mixed penalty function method, the minimum wall thickness required, the best thickness ratio and the modulus ratio of inner layer to outer layer are calculated for cases in which the external load and uniaxial compressive strength are known already. If the thickness and uniaxial compressive strength is given, the best thickness ratio and modulus ratio of inner layer to outer layer can also be proposed by using the mixed penalty function method.

Similar content being viewed by others

References

Wang R, Xiong ZH, Huang WB (1998) Foundation of plastic mechanics. Science Press, Beijing

Lu AZ, Zhang LQ (2008) Inversion of the functionally graded material for subvertical to improve its elastic limit bearing capacity. In: Proceedings of the tenth national symposium on rock mechanics and engineering. China Electric Power Press, Beijing, pp 131–137

Andrew JG, Senthil SV (2006) Two-dimensional optimization of material composition of functionally graded materials using meshless analyses and a genetic algorithm. Comput Methods Appl Mech Eng 195(44-47):5926–5948

Andrew JG, Senthil SV (2007) Multi-objective optimization of functionally graded materials with temperature-dependent material properties. Mater Des 28(6):1861–1879

Ootao Y, Tanigawa Y, Nakamura T (1999) Optimization of material composition of FGM hollow cylinder under thermal loading: a neural network approach. Compos Part B: Eng 30(4):415–422

Senthil SV, Jacob LP (2007) Multi-objective optimization of functionally graded thick shells for thermal loading. Compos Struct 81(3):386–400

Zhang XD, Wang SQ, Liu DQ (2002) Optimization of axial symmetrical FGM using genetic algorithm. J Beijing Univ Sci Technol 24(6):630–632

Guo ZH, Wang CZ (1991) Investigation of strength and failure criterion of concrete under multi-axial stresses. China Civil Eng J 24(3):1–14

Guo ZH (1994) Introduction of multiaxial strength of concrete. J Build Struct 15(6):72–75

Wu ZH, Wan YQ (1986) Mechanical optimum design. China Machine Press, Beijing

Acknowledgment

The study is supported by the National Natural Science Foundation of China (Grant No. 50874047).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lu, AZ., Xu, GS. & Zhang, LQ. Optimum design method for double-layer thick-walled concrete cylinder with different modulus. Mater Struct 44, 923–928 (2011). https://doi.org/10.1617/s11527-010-9676-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1617/s11527-010-9676-7