Abstract

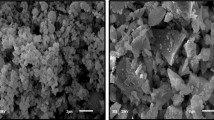

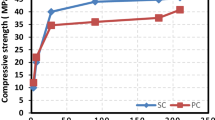

In this study, binary and ternary use of marble powder (MP) and ground granulated blast furnace slag (GGBFS) have been investigated in the production of self compacting mortars (SCMs). The marble powder was obtained as an industrial by-product during sawing, shaping, and polishing of marble. A total of 19 SCM mixtures were proportioned having a constant water-binder ratio of 0.40 and the total binder content of 550 kg/m3. The control mixture contained only portland cement (PC) as the binder while the remaining mixtures incorporated binary and ternary blends of PC, MP, and GGBFS. After mixing, the fresh properties of the SCM were tested for mini-slump flow diameter, mini-V funnel flow time, initial and final setting times, and viscosity. Moreover, compressive strength and ultrasonic pulse velocity of the hardened SCMs were measured. Test results indicated that the inclusion of MP increased the V-funnel flow time, setting times, and viscosity of SCMs whereas decreased the hardened properties. Using GGBFS, on the other hand, decreased the V-funnel flow time and viscosity while increased the setting times of SCMs.

Similar content being viewed by others

References

Courard L, Darimont A, Willem X, Geers C, Degeimbre R (2002) Repairing concretes with self-compacting concrete: testing methodology assessment. In: Proceedings of the first north American conference on the design and use of self-consolidating concrete, pp 267–274

Felekoğlu B, Tosun K, Baradan B, Altun A, Uyulgan B (2006) The effect of fly ash and limestone fillers on the viscosity and compressive strength of self-compacting repair mortars. Cement Concr Res 36:1719–1726. doi:10.1016/j.cemconres.2006.04.002

Khayat KH, Morin R (2002) Performance of self-consolidating concrete used to repair parapet wall in Montreal. In: Proceedings of the first north American conference on the design and use of self-consolidating concrete, pp 475–81

Felekoğlu B, Turkel S, Altuntas Y (2007) Effects of steel fiber reinforcement on surface wear resistance of self-compacting repair mortars. Cement Concr Compos 29:391–396. doi:10.1016/j.cemconcomp.2006.12.010

O’Flaherty FJ, Mangat PS (1999) Influence of constituents on the properties of self-compacting repair materials. In: Skarendahl A, Petersson Ö (eds) Proceedings of the first international RILEM symposium on self-compacting concretes, Stockholm, pp 263–274

Edamatsu Y, Nishida N, Ouchi M (1999) A rational mix-design method for self-compacting concrete considering interaction between coarse aggregate and mortar particles. In: Skarendahl A, Petersson Ö (eds) Proceedings of the first international RILEM symposium on self-compacting concrete, Stockholm, pp 309–320

Khayat KH, Guizani Z (1997) Use of viscosity-modifying admixture to enhance stability of fluid concrete. ACI Mater J 94:332–340

Yurigi M, Sakai M, Sakata N (1995) Viscosity agent and mineral admixtures for highly fluidized concrete. In: Sakai K, Banthia N, Gjorv O (eds) Proceedings of concrete under severe conditions: environment and loading E&FN Spon, pp 995–1004

Khayat KH (1998) Use of viscosity-modifying admixture to reduce top-bar effect of anchored bars cast with fluid concrete. ACI Mater J 95:158–167

Zhu W, Gibbs JC (2005) Use of different limestone and chalk powders in self-compacting concrete. Cement Concr Res 35:1454–1462. doi:10.1016/j.cemconres.2004.07.001

Sonebi M, Bartos PJM (1999) Hardened SCC and its bond with reinforcement. In: Skarendahl A, Petersson Ö (eds) Proceedings of the first international RILEM symposium on self-compacting concrete, Stockholm, pp 275–289

Fujiwara H, Nagataki S, Otsuki N, Endo H (1996) Study on reducing unit powder content of high-fluidity concrete by controlling powder particle size distribution. Concr Libr JSCE 28:117–128

Khayat KH, Manai K, Trudel A (1997) In situ mechanical properties of wall elements cast using self-consolidating concrete. ACI Mater J 94:491–500

Sedran T, de Larrard F (1999) Optimization of self compacting concrete, thanks to packing model. In: Skarendahl A, Petersson Ö (eds) Proceedings of the first international RILEM symposium on self-compacting concrete, Stockholm, pp 321–332

Khayat KH (1999) Workability, testing, and performance of self-consolidating concrete. ACI Mater J 96:346–353

Güneyisi E, Gesoğlu M (2008) Properties of self-compacting mortars with binary and ternary cementitious blends of fly ash and metakaolin. Mater Struct. doi:10.1617/s11527-007-9345-7

Bouzoubaa N, Lachemi M (2001) Self-compacting concrete incorporating high volumes of class F fly ash preliminary results. Cement Concr Res 31:413–420. doi:10.1016/S0008-8846(00)00504-4

Güneyisi E, Gesoğlu M (2007) Uçucu Kül ve Metakaolin İçeren Kendiliğinden Yerleşen Harçlar. In: Yapılarda Kimyasal Katkılar Sempozyumu ve Sergisi, Ankara, ss. 161–172 (in Turkish)

Sonebi M (2004) Medium strength self-compacting concrete containing fly ash: modelling using factorial experimental plans. Cement Concr Res 34:1199–1208. doi:10.1016/j.cemconres.2003.12.022

Gesoğlu M, Özbay E (2007) Effects of mineral admixtures on fresh and hardened properties of self-compacting concretes: binary, ternary and quaternary systems. Mater Struct 40:913–926

Celik MY, Sabah E (2007) Geological and technical characterisation of Iscehisar (Afyon-Turkey) marble deposits and the impact of marble waste on environmental pollution. J Environ Manage. doi:10.1016/j.jenvman.2007.01.004

Corinaldesi V, Moriconi G, Naik TR (2005) Characterization of marble powder for its use in mortar and concrete. UWM Center for by-product utilization, Report no: CBU-2005-09, Wisconsin, USA

Corinaldesi V, Moriconi G, Naik TR (2005) Characterization of marble powder for its use in mortar and concrete. In: Proceeding of CANMET/ACI international symposium on sustainable development of cement and concrete, Toronto, CANADA

Aruntaş HY, Dayı M, Tekin I, Birgül R, Şimşek O (2007) Effects of marble powder on the properties of self compacting concretes. In: Proceeding of second national symposium on chemical admixtures use in structures, Ankara, pp 161–172 (in Turkish)

ASTM C109/C 109M-99, (1999) Standard test method for compressive strength of hydraulic cement mortar. Annual book of ASTM standards, 04.01 Cement, Lime, Gypsum

EFNARC (2002) Specification and guidelines for self compacting concrete. Feb. 2002, pp 29–35. Free pdf copy downloadable from http://www.efnarc.org

ASTM C 403/403M-99, (1999) Standard test methods for time of setting of concrete mixtures by penetration resistance. Annual book of ASTM standards, 04.02 Concrete and Concrete Aggregates, pp 1–6

Barnes HA (1995) A review of slip (wall depletion) of polymer solutions, emulsions and particle suspensions in viscometers; its cause, character, and cure. J Non-Newton Fluid Mech 56:221–251

Brooks JJ, Megat Johari MA, Mazloom M (2000) Effect of admixtures on the setting time of high strength concrete. Cement Concr Compos 22:293–301. doi:10.1016/S0958-9465(00)00025-1

Alshamsi AM, Sabouni AR, Bushlaibi AH (1993) Influence of set-retarding superplasticizers and microsilica on the setting times of pastes at various temperatures. Cement Concr Res 23:592–598. doi:10.1016/0008-8846(93)90009-X

Naik TR, Singh SS (1997) Influence of fly ash on the setting and hardening characteristics of concrete systems. ACI Mater J 94:355–360

Eren O, Brooks JJ, Celik T (1995) Setting of fly ash and slag-cement concrete as effected by curing temperature. Cement Concr Aggr 17:11–17

Heikal M, El-Didamony H, Morsy MS (2000) Limestone-filled pozzolanic cement. Cement Concr Res 30:1827–1834. doi:10.1016/S0008-8846(00)00402-6

Bonavetti V, Donza H, Rahhal V, Irassar E (2000) Influence of initial curing on the properties of concrete containing limestone blended cement. Cement Concr Res 30:703–708. doi:10.1016/S0008-8846(00)00217-9

Whitehurst EA (1951) Soniscope tests concrete structures. J Am Concr Inst 47:443–444

Srinivasan CB, Narasimhan NL, Ilango SV (2003) Development of rapid-set high-strength cement using statistical experimental design. Cement Concr Res 33:1287–1292. doi:10.1016/S0008-8846(03)00041-3

Acknowledgements

Authors would like to acknowledge the supports of Gaziantep University-Office of Scientific Research Projects Coordination (GÜBAP) to carry out the present study. Moreover, the assistance of Mr. Ibrahim Kaygusuz, Mr. Melih Dallı, Mr. Levent Tekir and Mr. Serdar Genç during the experimental phase of the study are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Güneyisi, E., Gesoğlu, M. & Özbay, E. Effects of marble powder and slag on the properties of self compacting mortars. Mater Struct 42, 813–826 (2009). https://doi.org/10.1617/s11527-008-9426-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1617/s11527-008-9426-2