Abstract

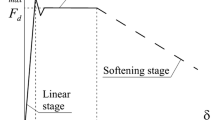

When fresh mortars are applied on a substrate they lose water by suction and by evaporation, sometimes very quickly, and they start suffering some shrinkage, while simultaneously hardening and getting stiffer. Because they are adherent to a rigid background—the wall—the deformation is restrained, stresses develop in the render and are partially transferred to the background. These phenomena can generate cracks on the rendering and damage on weak or friable masonry. Air lime renders also suffer these actions, even if they react in a different way compared to cement mortars: they sometimes have high shrinkage, although they have also some ductility (comparatively high rupture energy), developing lower stresses. New␣renders to apply on old walls must be mechanically compatible with old pre-existent materials, namely with old masonry: they should not produce damage and they must be able to␣protect the wall for a reasonable period of time.

In this paper a test is described to evaluate the performance of renders concerning restrained shrinkage, results obtained are discussed and conclusions are summarised about compatibility parameters and classification.

Similar content being viewed by others

References

Papayanni J (2005) Design and manufacture of repair mortars for interventions on monuments and historical buildings. In: RILEM (ed) Workshop “Repair mortars for Historic masonry”, TC RMH, Delft, 25–28 January 2005

Tamin PF (1986) Study of the mechanical behaviour of wall renderings. Ph.D. Thesis, École Nationale des Ponts et ChaussÉes (ENPC), Paris (Only available in French)

Penev D, Kawamura M (1992) A laboratory device for restrained shrinkage fracture of soil–cement mixtures. Mater Struct 25:115–120

Veiga MR, Abrantes V (1998) Improving the cracking resistance of rendering mortars. Influence of composition factors. In: XXV World Congress of Housing. IAHS, Lisbon, June/July 1998

Veiga MR (1998) A methodology to evaluate the cracking susceptibility of renders: equipment, tests and criteria. Experimental data. In: 5th Int. Masonry Confer, London, Oct. 1998

Veiga MR (2000) Methodology to evaluate the cracking susceptibility of mortars. Selection criteria of rendering and repointing mortars for ancient buildings. In: Seminar “Malte a vista com sabie locali nella conservazione degli edifici storici”, Polit. di Torino, Torino, July 2000, Invited paper

Veiga MR (2000) Influence of application conditions on the cracking susceptibility of renderings. In: RILEM (ed) Concrete science and engineering, vol 2, pp 134–140

Veiga MR (1994) Aparelho para medição de tensões originadas pela restrição da retracção em argamassas para revestimento de paredes. Concepção, projecto e testes realizados. LNEC, Lisbon. Report 35/94-NCCt

Magalhães AC, Veiga MR (2005) Estudo comparativo de possíveis soluções de argamassas para revestimentos de paredes de edifícios antigos. In: 1° Cong. Nac. “Argamassas de Construção”, Lisbon, 24–25 Nov. 2005

Velosa A, Veiga MR (2001) The use of pozzolans as additives in lime mortars for employment in building rehabilitation. In: Int. Sem. “Historical Constructions” 2001. Universidade do Minho, Guimarães, Nov. 2001

Velosa A, Veiga MR (2002) Use of additivated lime mortars for old building rehabilitation. Adapted test methods. In: Proc. 9th Int. Conf. “Durability of building materials and components”, Brisbane, Australia, March 2002

Velosa A, Veiga MR (2004) Parameters influencing the performance of lime mortars with pozzolanic additives: a testing campaign. In: ICOMOS (ed) 10th Int. Cong. “Deterioration and conservation of stone”, Stockolm, June/July 2004

Moropoulou A, Bakolas A, Moundoulas P, Aggelakoupoulou E, Anagnostopoulou S (2005) Strength development and lime reaction in mortars for repairing historic mortars. In: Elsevier (ed) Cement and concrete composites, vol 27, pp 289–294

Dunn E, Rapp G (2004) Characterization of mortars and pozzolanic materials from Umm al-Jimal. Stud Conserv 49:145–160

Maravelaki-Kalaitzaki P, Bakolas A, Moropoulou A (2003) Physico-chemical study of Cretan ancient mortars. In: Elsevier (ed) Cement and concrete research, vol 33, pp 651–661

Acknowledgements

This research is developed within the Projects “Development of methodologies for the assessment of moisture effects on ancient walls”— POCTI/ECM/46323/2002 and “Study of compatible mortars for the preservation of the constructed Heritage”—POCI/HEC/57890/2004, both with financial support of “Fundação para a Ciência e Tecnologia” of Portugal.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Veiga, M.R., Velosa, A.L. & Magalhães, A.C. Evaluation of mechanical compatibility of renders to apply on old walls based on a restrained shrinkage test. Mater Struct 40, 1115–1126 (2007). https://doi.org/10.1617/s11527-006-9209-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1617/s11527-006-9209-6