Highlights

-

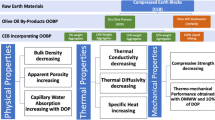

Use of olive core wastes as sand in self-compacting mortar (SCM).

-

The behavior of SCM with olive core waste is evaluated by the physico-mechanical and thermal properties of different mixes.

-

The bulk density and thermal conductivity are improved by using of olive core wastes.

Abstract

The recycling of organic wastes in the field of civil engineering is a very important process as long as the products to be obtained are not subjected to stringent quality standards. This research is a part of the general policy of saving energy and protecting the environment. Its aim is to study the possibility of developing a new insulating building material by recycling vegetable waste from the olive processing industry (olive core) that discarded in nature. After having been sorted, dried and then extruded in the form of grains, these wastes are incorporated as fine aggregate (sand) in the manufacturing of self-compacting mortar (SCM) by substituting the mass of sand with different percentages (10, 20, 30 40 and 50%). The physico-mechanical and thermal properties of the obtained SCMs are analyzed and compared to the control. The results of this study show a decrease in density and compressive strength of SCM by increasing the content of olive core wastes. However, the thermal properties of SCM are improved through replacing sand by such wastes, which could allow using olive waste core based SCM in various types of nonstructural components with intriguing insulating properties.

Graphic abstract

Similar content being viewed by others

Change history

17 August 2021

A Correction to this paper has been published: https://doi.org/10.1557/s43581-021-00010-y

References

A. Demirbas, Potential applications of renewable energy sources, biomass combustion problems in boiler power systems and combustion related environmental issues. Prog. Energy Combust. Sci. 31(2), 171–192 (2005). https://doi.org/10.1016/j.pecs.2005.02.002

S. Mucahit, Influence of expanded vermiculite on physical properties and thermal conductivity of clay bricks. Ceram. Int. 41(2), 2819–2827 (2015). https://doi.org/10.1016/j.ceramint.2014.10.102

J. J. Del Coz Díaz, P. J. García Nieto, J. Domínguez Hernández, A. Suárez Sánchez, Thermal design optimization of lightweight concrete blocks for internal one way spanning slabs floors by FEM, Energy Build. 41 (12), 1276–1287 (2009). https://doi.org/10.1016/j.enbuild.2009.08.005

S. Mucahit, A. Sedat, The use of recycled paper processing residues in making porous brick with reduced thermal conductivity. Ceram. Int. 35(7), 2625–2631 (2009). https://doi.org/10.1016/j.ceramint.2009.02.027

D.G. Leo Samuel, K. Dharmasastha, S.M. Nagendra, M. Prakash Maiya, Thermal comfort in traditional buildings composed of local and modern construction materials. Int. J. Sustain. Built Environ. 6(2), 463–475 (2017). https://doi.org/10.1016/j.ijsbe.2017.08.001

S. Alkheder, Y.T. Obaidat, M. Taamneh, Effect of olive waste (husk) on behavior of cement paste. Case Stud. Construc. Mater. 5, 19–25 (2016). https://doi.org/10.1016/j.cscm.2016.05.001

M.S. Al-Homoud, Performance characteristics and practical applications of common building thermal insulation materials. Build. Environ. 40(3), 353–366 (2005). https://doi.org/10.1016/j.buildenv.2004.05.013

M.A. Nabil, M. Al-A, F.A. Khaled, Mousa, , Performance of olive waste ash concrete exposed to elevated temperatures. Fire Saf. J. 44(3), 370–375 (2009). https://doi.org/10.1016/j.firesaf.2008.08.006

A.P. Gursel, H. Maryman, C. Ostertag, A life-cycle approach to environmental, mechanical, and durability properties of green concrete mixes with rice husk ash. J. Clean. Prod. 112(1), 823–836 (2016). https://doi.org/10.1016/j.jclepro.2015.06.029

M. Guendouz, F. Debieb, O. Boukendakdji, E.H. Kadri, M. Bentchikou, H. Soualhi, Use of plastic waste in sand concrete. J. Mater. Environ. Sci. 7(2), 382–389 (2016)

T. Blankendaal, P. Schuur, H. Voordijk, Reducing the environmental impact of concrete and asphalt: a scenario approach. J. Clean. Prod. 66, 27–36 (2014). https://doi.org/10.1016/j.jclepro.2013.10.012

D. Boukhelkhal, O. Boukendakdji, S. Kenai, E.H. Kadri, Combined effect of mineral admixture and curing temperature on mechanical behavior and porosity of SCC. Adv. Concret. Construc. 6(1), 69–85 (2018). https://doi.org/10.12989/acc.2018.6.1.069

K.H. Mo, U.J. Alengaram, M.Z. Jumaat, S.P. Yap, Feasibility study of high volume slag as cement replacement for sustainable structural lightweight oil palm shell concrete. J. Clean. Prod. 91, 297–304 (2015). https://doi.org/10.1016/j.jclepro.2014.12.021

H. Zhao, W. Sun, X. Wu, B. Gao, The properties of the self-compacting concrete with fly ash and ground granulated blast furnace slag mineral admixtures. J. Clean. Prod. 95, 66–74 (2015). https://doi.org/10.1016/j.jclepro.2015.02.050

B. Zhang, C.S. Poon, Use of furnace bottom ash for producing lightweight aggregate with thermal insulation properties. J. Clean. Prod. 99, 94–100 (2015). https://doi.org/10.1016/j.jclepro.2015.03.007

M. Singh, R. Siddique, Properties of concrete containing high volumes of coal bottom ash as fine aggregate. J. Clean. Prod. 91, 269–278 (2015). https://doi.org/10.1016/j.jclepro.2014.12.026

M. Guendouz, D. Boukhelkhal, Properties of flowable sand concrete containing ceramic wastes. J. Adhesion Sci Technol. 33(24), 2661–2683 (2019). https://doi.org/10.1080/01694243.2019.1653594

M. Guendouz, D. Boukhelkhal, A. Bourdot, O. Babachikh, A. Hamadouche, The effect of ceramic wastes on physical and mechanical properties of eco-friendly flowable sand concrete. Ceramic Materials. IntechOpen. 10, 2 (2020). https://doi.org/10.5772/intechopen.95041

S.R. Karade, Cement-bonded composites from lingo cellulosic wastes. Constr. Build. Mater. 24(8), 1323–1330 (2010). https://doi.org/10.1016/j.conbuildmat.2010.02.003

K.H. Mo, U.J. Alengaram, M.Z. Jumaat, A review on the use of agriculture waste material as lightweight aggregate for reinforced concrete structural members. Adv. Mater. Sci. Eng. 9, 365197 (2014). https://doi.org/10.1155/2014/365197

P. Shafigh, H.B. Mahmud, M.Z. Jumaat, M. Zargar, Agricultural wastes as aggregate in concrete mixtures: a review. Constr. Build. Mater. 53, 110–117 (2014). https://doi.org/10.1016/j.conbuildmat.2013.11.074

N.M. Al-Akhras, B.A. Abu-Alfoul, Effect of wheat straw ash on mechanical properties of autoclaved mortar. Cem. Concr. Res. 32(6), 859–863 (2002). https://doi.org/10.1016/S0008-8846(02)00716-0

F. Wu, C. Liu, L. Zhang, Y. Lu, Y. Ma, Comparative study of carbonized peach shell and carbonized apricot shell to improve the performance of lightweight concrete. Constr. Build. Mater. 188, 758–771 (2018). https://doi.org/10.1016/j.conbuildmat.2018.08.094

M. Guendouz, Dj. Boukhelkhal, Properties of dune sand concrete containing coffee waste, MATEC Web of Conferences, 149, 01039 (2018). doi:https://doi.org/10.1051/matecconf/201814901039

A. Agarwal, B. Nanda, D. Maity, Experimental investigation on chemically treated bamboo reinforced concrete beams and columns. Constr. Build. Mater. 71, 610–617 (2014). https://doi.org/10.1016/j.conbuildmat.2014.09.011

V. Agopyan, J.H. Savastano, V.M. John, M.A. Cincotto, Developments on vegetable fiber cement based materials in Sao Paulo, Brazil: an overview. Cem Concr. Compos. 27(5), 527–536 (2005). https://doi.org/10.1016/j.cemconcomp.2004.09.004

F. Pacheco-Torgal, S. Jalali, Cementitious building materials reinforced with vegetable fibres: a review. Constr. Build. Mater. 25(2), 575–581 (2011). https://doi.org/10.1016/j.conbuildmat.2010.07.024

A. Bourdot, C. Magniont, M. Lagouin, C. Niyigena, P. Evon, S. Amziane, Impact of bio-aggregates properties on the chemical interactions with mineral binder, application to vegetal concrete. J. Adv. Concr. Technol. 17(9), 542–558 (2019). https://doi.org/10.3151/jact.17.542

H. Binici, F. Yucegok, O. Aksogan, H. Kaplan, Effect of corncob, wheat straw, and plane leaf ashes as mineral admixtures on concrete durability. J. Mater. Civ. Eng. 20(7), 478–483 (2008)

N.M. Al-Akhras, M.Y. Abdulwahid, Utilisation of olive waste ash in mortar mixes. Struct. Concr. 11(4), 221–228 (2010). https://doi.org/10.1680/stco.2010.11.4.221

E. Aprianti, P. Shafigh, S. Bahri, J.N. Farahani, Supplementary cementitious materials origin from agricultural wastes—a review. Constr. Build. Mater. 74, 176–187 (2015). https://doi.org/10.1016/j.conbuildmat.2014.10.010

M. Safiuddin, M.A. Salam, M.Z. Jumaat, Utilization of palm oil fuel ash in concrete: a review. J. Civ. Eng. Manag. 17(2), 234–247 (2011)

L. Salmabanu, L. Ta-Wui, L. Ismail, Incorporation of natural waste from agricultural and aquacultural farming as supplementary materials with green concrete: a review. Compos. B 175, 107076 (2019). https://doi.org/10.1016/j.compositesb.2019.107076

G.H.M.J.S. De Silva, S. Vishvalingam, T. Etampawala, Effect of waste rice husk ash from rice husk fuelled brick kilns on strength, durability and thermal performances of mortar. Constr. Build. Mater. 268, 121794 (2021). https://doi.org/10.1016/j.conbuildmat.2020.121794

L. Kerrai, B. Salah, S. Roland, R. Fetiha, Valorisation of organic waste: Use of olive kernels and pomace for cement manufacture. J. Clean. Prod. 277, 123703. https://doi.org/10.1016/j.jclepro.2020.123703 (2020).

J. Cuenca, J. Rodríguez, M. Martín-Morales, Z. Sánchez-Roldán, M. Zamorano, Effects of olive residue biomass fly ash as filler in self-compacting concrete. Constr. Build. Mater. 40, 702–709 (2013). https://doi.org/10.1016/j.conbuildmat.2012.09.101

M. Sutcu, S. Ozturk, E. Yalamac, O. Gencel, Effect of olive mill waste addition on the properties of porous fired clay bricks using Taguchi method. J. Environ. Manag. 181, 185–192 (2016). https://doi.org/10.1016/j.jenvman.2016.06.023

A. Eisa, Properties of concrete incorporating recycled post-consumer environmental wastes. Int J Concr Struct Mater. 8(3), 251–258 (2014). https://doi.org/10.1007/s40069-013-00659

C. Leiva, F.L. Vilches, J. Vale, C. Fernández-Pereira, Influence of the type of ash on the fire resistance characteristics of ash-enriched mortars. Fuel 84(11), 1433–1439 (2005). https://doi.org/10.1016/j.fuel.2004.08.031

N.M. Al-Akhras, Performance of olive waste ash concrete exposed to alkali-Silica reaction. Struct. Concr. J. 13(4), 221–226 (2012). https://doi.org/10.1002/suco.201100058

M.N. Al-Akhras, K.M. Al-Akhras, M.F. Attom, Performance of olive waste ash concrete exposed to elevated temperatures. Fire Saf. J. 44(3), 370–375 (2009). https://doi.org/10.1016/j.firesaf.2008.08.006

H. Mekki, M. Anderson, M. Benzina, E. Ammar, Valorization of olive mill waste water by its incorporation in building bricks. J. Hazard. Mater. 158(2–3), 308–315 (2008). https://doi.org/10.1016/j.jhazmat.2008.01.104

M.D. La Rubia-García, A. Yebra-Rodríguez, D. Eliche-Quesada, F.A. Corpas-Iglesias, A. Lopez-Galindo, Assessment of olive mill solid residue (pomace) as an additive in lightweight brick production. Const. Build. Mater. 36, 495–500 (2012). https://doi.org/10.1016/j.conbuildmat.2012.06.009

F. Barreca, C.R. Fichera, Use of olive stone as an additive in cement lime mortar to improve thermal insulation. Energy Build. 62, 507–513 (2013). https://doi.org/10.1016/j.enbuild.2013.03.040

EFNARC recommendations, The European guidelines for self-compacting concrete, Specification, Production and use, EFNARC Edition (United Kingdom, 2002), p. 63.

Y. Edamatsu, T. Sugamata, M. Ouchi, A mix-design method for self-compacting concrete based on mortar flow and funnel tests. In: Proceedings of 3rd international symposium on self-compacting concrete, Reykjavik, Iceland, 345–55 (2003).

H. Okamura, K. Ozawa, Mix-design for self-compacting concrete. Concrete Library of JSCE 25, 107–127 (1995)

P.R. De Matos, R. Pilar, L.H. Bromerchenkel, R.A. Schankoski, P.J.P. Gleize, J. De Brito, Self-compacting mortars produced with fine fraction of calcined waste foundry sand (WFS) as alternative filler: fresh-state, hydration and hardened-state properties. J. Clean. Prod. 252, 119871 (2020). https://doi.org/10.1016/j.jclepro.2019.119871

A. Lozano-Lunar, P.R. Da Silva, J. De Brito, J.M. Fernandez, J.R. Jimenez, Safe use of electric arc furnace dust as secondary raw material in self-compacting mortars production. J. Clean. Prod. 211, 1375–1388 (2019). https://doi.org/10.1016/j.jclepro.2018.12.002

A. Lozano-Lunar, I. Dubchenko, S. Bashynskyi, A. Rodero, J.M. Fernández, J.R. Jiménez, Performance of self-compacting mortars with granite sludge as Aggregate. Constr. Build. Mater. 251, 118998 (2020). https://doi.org/10.1016/j.conbuildmat.2020.118998

A. Tuaum, S. Shitote, W. Oyawa, Experimental study of self-compacting mortar incorporating recycled glass aggregate. Buildings 8, 15 (2018). https://doi.org/10.3390/buildings8020015

A. Santamaría, J.J. Gonzalez, M.M. Losanez, M. Skaf, V. Ortega-Lopez, The design of self-compacting structural mortar containing steelmaking slags as aggregate. Cement Concr. Compos. 111, 103627 (2020). https://doi.org/10.1016/j.cemconcomp.2020.103627

Effect on physical and mechanical properties, B. Safi, M. Saidi, Dj. Aboutaleb, M. Maallem, The use of plastic waste as fine aggregate in the self-compacting mortars. Constr. and Build. Mater. 43, 436–442 (2013). https://doi.org/10.1016/j.conbuildmat.2013.02.049

B. Safi, M. Saidi, A. Daoui, A. Bellal, A. Mechekak, K. Toumi, The use of seashells as a fine aggregate (by sand substitution) in self-compacting mortar (SCM). Constr. Build. Mater. 78, 430–438 (2015). https://doi.org/10.1016/j.conbuildmat.2015.01.009

T. Bouziani, M. Bederina, M. Hadjoudja, Effect of dune sand on the properties of flowing sand-concrete (FSC). Int. J. Concr. Struct. Mater. 6(1), 59–64 (2012). https://doi.org/10.1007/s40069-012-0006-z

NF EN 196–1, Methods of testing cements—Part 1: determination of strengths, AFNOR (2016).

NF EN 12390–7, Tests for hardened concrete—Part 7: Density of hardened concrete, AFNOR (2019).

NF EN 13057, Products and systems for the protection and repair of concrete structures - Test methods - Determination of capillary absorption, AFNOR (2002).

NF P15–433, Methods of cements testing—Determination of shrinkage and swelling, AFNOR (1994).

NF EN 993–15, Test methods for dense shaped refractories—Part 15: Determination of thermal conductivity by the hot wire method (parallel), AFNOR (2005).

D.K. Panesar, B. Shindman, The mechanical, transport and thermal properties of mortar and concrete containing waste cork. Cement Concr. Compos. 34(9), 982–992 (2012). https://doi.org/10.1016/j.cemconcomp.2012.06.003

M. Cabrera, A.P. Galvín, F. Agrela, M.D. Carvajal, J. Ayuso, Characterisation and technical feasibility of using biomass bottom ash for civil infrastructures. Constr. Build. Mater. 58, 234–244 (2014). https://doi.org/10.1016/j.conbuildmat.2014.01.087

B. Carrasco, N. Cruz, J. Terrados, F.A. Corpas, L. Pérez, An evaluation of bottom ash from plant biomass as a replacement for cement in building blocks. Fuel 118, 272–280 (2014). https://doi.org/10.1016/j.fuel.2013.10.077

G.B. Manuel, B. Auxi, A. Francisco, R.J. José, J. De Brito, Mechanical performance of bedding mortars made with olive biomass bottom ash. Constr. Build. Mater. 112, 699–707 (2016). https://doi.org/10.1016/j.conbuildmat.2016.02.065

L. Stefania, R. Chiara, M. Francesco, S. Pietro, C. Caterina, P. Giovanni, Characterization of biomass-based materials for building applications: the case of straw and olive tree waste. Ind. Crops Prod. 147(112229), 1–12 (2020). https://doi.org/10.1016/j.indcrop.2020.112229

T. Canan, S. Ozkan, T. Mehmet Ali, A comparative study on the thermal conductivities and mechanical properties of lightweight concretes, Energy Build. 151, 469–475 (2017). https://doi.org/10.1016/j.enbuild.2017.07.013

S. Djadouf, A. Tahakourt, N. Chelouah, D. Merabet, Use of olive pomace and hay as additions in the manufacture of terracotta bricks, International seminar, innovation & valuation in Civil Engineering & Building Materials, 1O-051.

S. Mucahit, O. Savas, Y. Emre, G. Osman, Effect of olive mill waste addition on the properties of porous fired clay bricks using Taguchi method. J. Environ. Manag. 181, 185–192 (2016). https://doi.org/10.1016/j.jenvman.2016.06.023

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Boukhelkhal, D., Guendouz, M., Bourdot, A. et al. Elaboration of bio-based building materials made from recycled olive core. MRS Energy & Sustainability 8, 98–109 (2021). https://doi.org/10.1557/s43581-021-00006-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43581-021-00006-8