Abstract

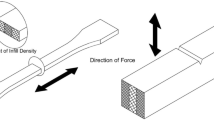

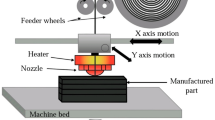

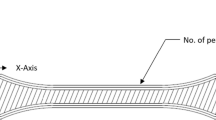

This work evaluated the mechanical behavior of FDM-printed parts of virgin (v-PLA) and recycled PLA (r-PLA) based on a factorial design, with ultimate tensile strength (UTS) as the response variable and PLA type, geometric pattern (linear, tridimensional, and hexagonal), and infill percentage (33%, 66%, and 100%) as factors. The v-PLA results showed that the strength increased as the infill was greater or with the geometric pattern change from tridimensional (25–37 MPa) to linear (31–44 MPa) and hexagonal (35–46 MPa); however, r-PLA showed minimal variation in UTS regardless of the factors and levels evaluated (1723 MPa). The optimal UTS (46 MPa) was achieved with v-PLA, hexagonal pattern and 100% infill, while fracture analysis indicated high concentration of air bubbles in r-PLA. Understanding the mechanical behavior of r-PLA based on statistical reliability contributes to the advancement of efficient design and sustainable manufacturing technologies.

Graphical abstract

Similar content being viewed by others

Data availability

Data available upon request.

References

K. Bassett, R. Carriveau, D.S.K. Ting, Sust. Ener. Technols. Asses. (2015). https://doi.org/10.1016/j.seta.2015.01.002

A. Kafle, E. Luis, R. Silwal, H.M. Pan, P.L. Shrestha, A.K. Bastola, Polymers (2021). https://doi.org/10.3390/polym13183101

P. Sammaiah, K. Rushmamanisha, N. Praveenadevi, I. Rajasri Reddy, IOP Conf. Ser. Mater. Sci. Eng. (2020) https://doi.org/10.1088/1757-899X/981/4/042021

N. Escalona-Contreras, P. Merino-Kutscher, R. Cartes-Velásquez, CES Odontol. (2021). https://doi.org/10.21615/cesodon.5939

E. Balla, V. Daniilidis, G. Karlioti, T. Kalamas, M. Stefanidou, N.D. Bikiaris, A. Vlachopoulos, I. Koumentakou, D.N. Bikiaris, Polymers (2021). https://doi.org/10.3390/polym13111822

A.J.R. Lasprilla, G.A.R. Martinez, B.H. Lunelli, A.L. Jardini, R.M. Filho, Biotechnol. Adv. (2012). https://doi.org/10.1016/j.biotechadv.2011.06.019

J.D. Badia, A. Ribes-Greus, Eur. Polym. J. (2016). https://doi.org/10.1016/j.eurpolymj.2016.09.005

A. Rahimi, J.M. García, Nat. Rev. Chem. (2017). https://doi.org/10.1038/s41570-017-0046

S. Farah, D.G. Anderson, R. Langer, Adv. Drug Deliv. Rev. (2016). https://doi.org/10.1016/j.addr.2016.06.012

N. Singh, D. Hui, R. Singh, I.P.S. Ahuja, L. Feo, F. Fraternali, Compos. B Eng. (2017). https://doi.org/10.1016/j.compositesb.2016.09.013

N. López-Rodríguez, A. López-Arraiza, E. Meaurio, J.R. Sarasua, Polym. Eng. Sci. (2006). https://doi.org/10.1002/pen.20609

S. Laske, W. Ziegler, M. Kainer, J. Wuerfel, C. Holzer, Polym. Eng. Sci. (2015). https://doi.org/10.1002/pen.24176

V. Toragall, N. Jayapala, B. Vallikannan, Int. J. Biol. Macromol. (2020). https://doi.org/10.1016/j.ijbiomac.2020.02.104

N.C. Farias, I. Major, D. Devine, M.B. Fournet, R. Pezzoli, S.F. Taghinezhad, M. Hesabi, Polym. Eng. Sci. (2022). https://doi.org/10.1002/pen.25962

J.J. Laureto, J.M. Pearce, Polym. Test. (2018). https://doi.org/10.1016/j.polymertesting.2018.04.029

A. Lanzotti, M. Martorelli, S. Maietta, S. Gerbino, F. Penta, A. Gloria, Proc. CIRP (2019). https://doi.org/10.1016/j.procir.2019.02.030

D. Popescu, A. Zapciu, C. Amza, F. Baciu, R. Marinescu, Polym. Test. (2018). https://doi.org/10.1016/j.polymertesting.2018.05.020

S.L. Rodríguez-Reyna, C. Mata, J.H. Díaz-Aguilera, H.R. Acevedo-Parra, F. Tapia, Mater. Today Commun. (2022). https://doi.org/10.1016/j.mtcomm.2022.104774

M. Algarni, Polymers (2021). https://doi.org/10.3390/polym13020237

Acknowledgments

J.H. Díaz-Aguilera thanks CONAHCYT for the scholarship provided with CVU 929098.

Funding

Not applicable. No funding was received by any of the authors for this project.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Rodríguez-Reyna, S.L., Díaz-Aguilera, J.H., García-Contreras, J.P. et al. Evaluation of the mechanical behavior of fused deposition modeling (FDM)-printed virgin and recycled PLA parts using factorial design. MRS Advances 9, 187–192 (2024). https://doi.org/10.1557/s43580-023-00743-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43580-023-00743-7