Abstract

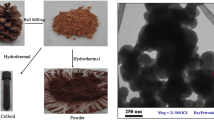

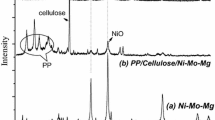

Carbon nanostructures were synthesized using coniferous exudate commonly known as rosin as precursor due their high carbon content, low cost, and because it is a renewable material with high availability. The synthesis of the carbon nanostructures (CNSs) was carried out by the chemical vapor deposition (CVD) technique with a stainless steel AISI 304 bar as catalyst and argon as the carrier gas at 750, 800, 850, and 900 °C during 30 and 60 min at atmospheric pressure. The scanning electron microscopy demonstrated the formation of mostly spherical and some tubular carbon nanostructures of different diameters. The carbon spheres at higher temperatures are more defined; however, they tend to agglomerate. Energy-dispersive spectroscopy analysis demonstrated 84–99% of carbon, 0.25–15.69% of oxygen, and traces of chromium and iron. The Fourier transform infrared spectra indicated the presence of OH, C=O, C=C, and CHx functional groups. The presence of hydroxyl and carbonyl groups can be useful for higher interaction of CNSs with different materials in some usage. Typical D, G, and G′ bands of CNSs were observed by Raman spectroscopy. The ID/IG ratio show high degree of graphitization of CNSs. The value of IG′/IG ratio indicates that the CNSs are multilayer. X-ray diffraction patterns show that the CNSs obtained at 30 min are more crystalline. The CNSs synthesized from rosin by CVD can be used in different fields of science and technology.

Graphical abstract

Raman spectra of nanostructures obtained from rosin by CVD

Similar content being viewed by others

Data availability

All data generated or analyzed during this study are included in this published article.

References

W. Wang, Y. Hou, D. Martinez, D. Kurniawan, W.H. Chiang, P. Bartolo, Polymers (2020). https://doi.org/10.3390/polym12122946

J.M. Ambriz-Torres, C.J. Gutiérrez-García, D.L. García-Ruiz, J.J. Contreras-Navarrete, F.G. Granados-Martínez, N. Flores-Ramírez, M.L. Mondragón-Sánchez, L. García-González, L. Zamora-Peredo, O. Hernández-Cristóbal, F. Méndez, L. Domratcheva-Lvova, J. Mater. Sci.: Mater. Electron. (2020). https://doi.org/10.1007/s10854-020-02868-z

Y.Z. Jin, C. Gao, W.K. Hsu, Y. Zhu, A. Huczko, M. Bystrzejewski, D.R. Walton, Carbon (2005). https://doi.org/10.1016/j.carbon.2005.03.002

A.R.K. Rezaei, Dia Rel Mater. (2018). https://doi.org/10.1016/j.diamond.2018.02.003

H.J. Muñoz-Flores, J.H. Ramos, J.T. Sáenz-Reyes, R. Reynoso-Santos, R. Barrera-Ramírez, Rev. Mex de Cie For. (2022). https://doi.org/10.29298/rmcf.v13i73.1188

S. Ravi, S. Vadukumpully, J. Environ. Chem. Eng. (2016). https://doi.org/10.1016/j.jece.2015.11.026

A.A. Aboul-Enein, A.E. Awadallah, S.M. Solyman, H.A. Ahmed, Fuller. Nanotub. Carbon Nanostruct. (2022). https://doi.org/10.1080/1536383X.2021.2023133

P. Anastas, N. Eghbali, Chem. Soc. Rev. (2010). https://doi.org/10.1039/B918763B

K. Awasthi, R. Kumar, R.S. Tiwari, O.N. Srivastava, J. Exp. Nanosci. (2010). https://doi.org/10.1080/17458081003664159

S.P. Somani, P.R. Somani, M. Tanemura, S.P. Lau, M. Umeno, Curr. Appl. Phys. (2009). https://doi.org/10.1016/j.cap.2008.01.002

K. Koziol, B.O. Boskovic, N. Yahya, Carbon Oxide Nanostruct. (2011). https://doi.org/10.1007/8611_2010_12

L. Camilli, M. Scarselli, S. Del Gobbo, P. Castrucci, F. Nanni, E. Gautron, S. Leframt, M. De Crescenzi, Carbon (2011). https://doi.org/10.1016/j.carbon.2011.04.014

Q.L. Yan, M. Gozin, F.Q. Zhao, A. Cohen, S.P. Pang, Nanoscale (2016). https://doi.org/10.1039/c5nr07855e

P. Ghosh, T. Soga, R.A. Afre, T. Jimbo, J. Alloys Compd. (2008). https://doi.org/10.1016/j.jallcom.2007.08.027

M. Inagaki, Carbon 35, 711 (1997)

R. Li, A. Shahbazi, Trends Renew. Energy (2015). https://doi.org/10.17737/tre.2015.1.1.009

J.M. Ambriz-Torres, L.D. Lvova, C.J. García, P. Garnica-González, O. Aguilar-García, J.J. Contreras-Navarrete, MRS Adv. (2022). https://doi.org/10.1557/s43580-022-00338-8

J.A. Guzmán-Fuentes, J.J. Contreras-Navarrete, E. Cadenas-Calderón, J.M. Ambriz-Torres, D.L. García-Ruíz, C.J. Gutiérrez-García, L. Domratcheva-Lvova, MRS Adv. (2020). https://doi.org/10.1557/adv.2020.399

C.J. Gutiérrez-García, J.M. Ambriz-Torres, J.J. Contreras-Navarrete, F.G. Granados-Martínez, D.L. García-Ruiz, L. García-González, L. Domratcheva-Lvova, Physica E (2019). https://doi.org/10.1016/j.physe.2019.04.007

D.L. García-Ruiz, F.G. Granados-Martínez, C.J. Gutiérrez-García, J.M. Ambriz-Torres, J.J. Contreras-Navarrete, N. Flores-Ramírez, L. Domratcheva-Lvova, Rev. Mex. Ing. Quí. (2019). https://doi.org/10.24275/uam/izt/dcbi/revmexingquim/2019v18n2/GarciaR

K.R. Gbashi, Iraqi J. Phys. (2017). https://doi.org/10.30723/ijp.v15i35.55

K. Saxena, P. Kumar, V.K. Jain, New Carbon Mater. (2011). https://doi.org/10.1016/S1872-5805(11)60088-7

E.F. Antunes, A.O. Lobo, E.J. Corat, V.J. Trava-Airoldi, Carbon (2007). https://doi.org/10.1016/j.carbon.2007.01.003

M.A. Ermakova, D.Y. Ermakov, A.L. Chuvilin, G.G. Kuvshinov, J. Catal. (2001). https://doi.org/10.1006/jcat.2001.3243

M.S. Dresselhaus, G. Dresselhaus, R. Saito, A. Jorio, Phys. Rep. (2005). https://doi.org/10.1016/j.physrep.2004.10.006

L.G. Cançado, K. Takai, T. Enoki, M. Endo, Y.A. Kim, H. Mizusaki, A. Jorio, L.N. Coelho, R. Magalhães-Paniago, M.A. Pimenta, Appl. Phys. Lett. (2006). https://doi.org/10.1063/1.2196057

R.W. Wyckoff, Cryst. Struct. 1, 7 (1963)

J. Fayos, J. Solid State Chem. (1999). https://doi.org/10.1006/jssc.1999.8448

A.N. Mohan, B. Manoj, Int. J. Electrochem. Sci. 7, 9537 (2012)

G.C. Allen, K.R. Hallam, J.A. Jutson, Powder Diffr. (1995). https://doi.org/10.1017/S0885715600014779

Acknowledgments

CIC of the Universidad Michoacana de San Nicolás de Hidalgo, MICRONA of the Universidad Veracruzana, Tecnológico Nacional México/Instituto Tecnológico de Morelia, ENES UNAM Campus Morelia, and CONACYT México.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

We have no conflicts of interest to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ignacio-De la Cruz, J.L., Gutiérrez-García, C.J., Poiré-De la Cruz, D.R. et al. Carbon nanomaterials synthesis by chemical vapor deposition from conifer exudate. MRS Advances 7, 668–673 (2022). https://doi.org/10.1557/s43580-022-00372-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43580-022-00372-6