Abstract

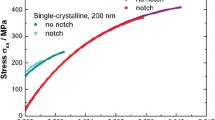

We investigated the tensile load–unload response and inelastic strain recovery in freestanding ultrafine-grained aluminum films with highly dissimilar texture at strain rates ranging from ~ 10–6/s to 10–3/s. For (110) textured bicrystalline films, the flow stress was nearly insensitive to strain rate and inelastic strain recovery both during and after unloading was small, leading to fairly low stress–strain hysteresis. In contrast, there was a substantial increase in flow stress for non-textured films with increasing strain rate. Furthermore, there was significant inelastic strain recovery both during and after unloading, resulting in a large stress–strain hysteresis. Interestingly, while the proportion of inelastic strain recovered during and after unloading varied with strain rate, the total strain recovery remained nearly constant. These observations underscore the influence of crystallographic texture and strain rate on the deformation mechanisms as well as the macroscopic behavior of ultrafine-grained metal films.

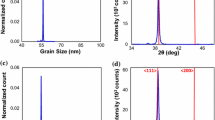

Graphic abstract

Similar content being viewed by others

Data availability

All the experimental data in the manuscript are available upon request from the corresponding author.

References

R. Schwaiger, B. Moser, M. Dao, N. Chollacoop, S. Suresh, Some critical experiments on the strain-rate sensitivity of nanocrystalline nickel. Acta Mater. 51, 5159–5172 (2003). https://doi.org/10.1016/S1359-6454(03)00365-3

I. Chasiotis, C. Bateson, K. Timpano, A.S. McCarty, N.S. Barker, J.R. Stanec, Strain rate effects on the mechanical behavior of nanocrystalline Au films. Thin Solid Films 515, 3183–3189 (2007). https://doi.org/10.1016/j.tsf.2006.01.033

Y. Wang, A. Hamza, E. Ma, Temperature-dependent strain rate sensitivity and activation volume of nanocrystalline Ni. Acta Mater. 54, 2715–2726 (2006). https://doi.org/10.1016/j.actamat.2006.02.013

D.S. Gianola, D.H. Warner, J.F. Molinari, K.J. Hemker, Increased strain rate sensitivity due to stress-coupled grain growth in nanocrystalline Al. Scr. Mater. 55, 649–652 (2006). https://doi.org/10.1016/j.scriptamat.2006.06.002

J. Chen, L. Lu, K. Lu, Hardness and strain rate sensitivity of nanocrystalline Cu. Scr. Mater. 54, 1913–1918 (2006). https://doi.org/10.1016/j.scriptamat.2006.02.022

F. Dalla Torre, H. Van Swygenhoven, M. Victoria, Nanocrystalline electrodeposited Ni: microstructure and tensile properties. Acta Mater. 50, 3957–3970 (2002)

J. Rajagopalan, C. Rentenberger, H. Peter Karnthaler, G. Dehm, M.T.A. Saif, In situ TEM study of microplasticity and Bauschinger effect in nanocrystalline metals. Acta Mater. 58, 4772–4782 (2010). https://doi.org/10.1016/j.actamat.2010.05.013

J. Rajagopalan, M.T.A. Saif, Effect of microstructural heterogeneity on the mechanical behavior of nanocrystalline metal films. J. Mater. Res. 26, 2826–2832 (2011). https://doi.org/10.1557/jmr.2011.316

E. Izadi, J. Rajagopalan, Texture dependent strain rate sensitivity of ultrafine-grained aluminum films. Scr. Mater. 114, 65–69 (2016). https://doi.org/10.1016/j.scriptamat.2015.12.003

E. Izadi, S. Opie, H. Lim, P. Peralta, J. Rajagopalan, Effect of plastic anisotropy on the deformation behavior of bicrystalline aluminum films—experiments and modeling. Acta Mater. 142, 58–70 (2018). https://doi.org/10.1016/j.actamat.2017.09.038

K.N. Jonnalagadda, I. Chasiotis, S. Yagnamurthy, J. Lambros, J. Pulskamp, R. Polcawich, M. Dubey, Experimental investigation of strain rate dependence of nanocrystalline Pt films. Exp. Mech. 50, 25–35 (2010). https://doi.org/10.1007/s11340-008-9212-7

N.J. Karanjgaokar, C.-S. Oh, J. Lambros, I. Chasiotis, Inelastic deformation of nanocrystalline Au thin films as a function of temperature and strain rate. Acta Mater. 60, 5352–5361 (2012). https://doi.org/10.1016/j.actamat.2012.06.018

H. Niwa, M. Kato, Epitaxial growth of Al on Si (001) by sputtering. Appl. Phys. Lett. 59, 543–545 (1991)

J.H. Han, M.T.A. Saif, In situ microtensile stage for electromechanical characterization of nanoscale freestanding films. Rev. Sci. Instrum. 77, 045102 (2006). https://doi.org/10.1063/1.2188368

F. Dalla Torre, P. Spätig, R. Schäublin, M. Victoria, Deformation behaviour and microstructure of nanocrystalline electrodeposited and high pressure torsioned nickel. Acta Mater. 53, 2337–2349 (2005). https://doi.org/10.1016/j.actamat.2005.01.041

M. Dao, L. Lu, R.J. Asaro, J.T.M. De Hosson, E. Ma, Toward a quantitative understanding of mechanical behavior of nanocrystalline metals. Acta Mater. 55, 4041–4065 (2007). https://doi.org/10.1016/j.actamat.2007.01.038

S.S. Shishvan, L. Nicola, E. Van der Giessen, Bauschinger effect in unpassivated freestanding thin films. J. Appl. Phys. 107, 093529 (2010). https://doi.org/10.1063/1.3407505

E. Izadi, A. Darbal, R. Sarkar, J. Rajagopalan, Grain rotations in ultrafine-grained aluminum films studied using in situ TEM straining with automated crystal orientation mapping. Mater. Des. 113, 186–194 (2017). https://doi.org/10.1016/j.matdes.2016.10.015

A. Kashiwar, H. Hahn, C. Kübel, In situ TEM observation of cooperative grain rotations and the bauschinger effect in nanocrystalline palladium. Nanomater. Basel Switz. 11, 432 (2021). https://doi.org/10.3390/nano11020432

F. Mompiou, D. Caillard, M. Legros, H. Mughrabi, In situ TEM observations of reverse dislocation motion upon unloading in tensile-deformed UFG aluminium. Acta Mater. 60, 3402–3414 (2012). https://doi.org/10.1016/j.actamat.2012.02.049

K.M. Davoudi, L. Nicola, J.J. Vlassak, Bauschinger effect in thin metal films: Discrete dislocation dynamics study. J. Appl. Phys. 115, 013507 (2014). https://doi.org/10.1063/1.4861147

R. Berlia, P. Rasmussen, S. Yang, J. Rajagopalan, Tensile behavior and inelastic strain recovery of Cu-Co nanolaminates. Scr. Mater. 197, 113781 (2021). https://doi.org/10.1016/j.scriptamat.2021.113781

L. Thilly, P.O. Renault, S. Van Petegem, S. Brandstetter, B. Schmitt, H. Van Swygenhoven, V. Vidal, F. Lecouturier, Evidence of internal Bauschinger test in nanocomposite wires during in situ macroscopic tensile cycling under synchrotron beam. Appl. Phys. Lett. 90, 241907 (2007). https://doi.org/10.1063/1.2748325

L. Thilly, S.V. Petegem, P.-O. Renault, F. Lecouturier, V. Vidal, B. Schmitt, H.V. Swygenhoven, A new criterion for elasto-plastic transition in nanomaterials: Application to size and composite effects on Cu-Nb nanocomposite wires. Acta Mater. 57, 3157–3169 (2009). https://doi.org/10.1016/j.actamat.2009.03.021

Q. Qin, S. Yin, G. Cheng, X. Li, T.-H. Chang, G. Richter, Y. Zhu, H. Gao, Recoverable plasticity in penta-twinned metallic nanowires governed by dislocation nucleation and retraction. Nat. Commun. 6, 5983 (2015). https://doi.org/10.1038/ncomms6983

Acknowledgments

This project was funded by the National Science Foundation (NSF) Grant DMR 1454109. The authors would like to gratefully acknowledge the use of facilities at the Eyring Materials Center and ASU Nanofab at Arizona State University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Rights and permissions

About this article

Cite this article

Izadi, E., Berlia, R. & Rajagopalan, J. Strain rate dependence of inelastic strain recovery in ultrafine-grained Al films with different textures. MRS Advances 6, 489–494 (2021). https://doi.org/10.1557/s43580-021-00100-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43580-021-00100-6