Abstract

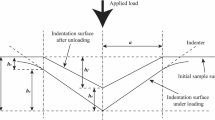

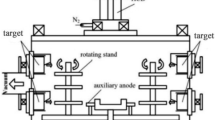

Nix–Gao’s factor (81/2) was replaced with (4.5Ct2) using variable constraint factor (Ct) for size-dependent analysis of crystalline coatings. Experimental investigations on annealed NiB coating (5 wt% boron) aimed at defense applications involved twelve Berkovich nanoindentation tests (displacements: 500, 1000, and 1500 nm; strain rates: 0.05, 0.1, 0.15, and 0.20 s−1). SEM and XRD analyzed cauliflower-type surface morphology and crystallinity. NiB coatings exhibited Intrinsic hardness (H0) of 9.65 ± 0.26 GPa, material characteristic length (h*) of 194.8 ± 10 nm, and elastic modulus (E) of 264 ± 10 GPa. Indentation size effects of these coatings attributed to increased geometrically necessary dislocation density.

Graphical abstract

Similar content being viewed by others

Data availability

The data presented in this research are obtainable upon reasonable request from the corresponding author.

References

Z.Y. Liang, G.M. Pharr, Decoupling indentation size and strain rate effects during nanoindentation: a case study in tungsten. J. Mech. Phys. Solids 165, 104935 (2022). https://doi.org/10.1016/j.jmps.2022.104935

J. Wang, T. Volz, S.M. Weygand, R. Schwaiger, The indentation size effect of single-crystalline tungsten revisited. J. Mater. Res. 36, 2166–2175 (2021). https://doi.org/10.1557/s43578-021-00221-6

I. Manika, J. Maniks, Size effects in micro- and nanoscale indentation. Acta Mater. 54, 2049–2056 (2006). https://doi.org/10.1016/j.actamat.2005.12.031

W.D. Nix, Elastic and plastic properties of thin films on substrates: nanoindentation techniques. Mater. Sci. Eng. A 234–236, 37–44 (1997). https://doi.org/10.1016/S0921-5093(97)00176-7

L. Lorenz, T. Chudoba, S. Makowski, M. Zawischa, F. Schaller, V. Weihnacht, Indentation modulus extrapolation and thickness estimation of ta-C coatings from nanoindentation. J. Mater. Sci. 56, 18740–18748 (2021). https://doi.org/10.1007/s10853-021-06448-2

S.M. Han, R. Shah, R. Banerjee, G.B. Viswanathan, B.M. Clemens, W.D. Nix, Combinatorial studies of mechanical properties of Ti–Al thin films using nanoindentation. Acta Mater. 53, 2059–2067 (2005). https://doi.org/10.1016/j.actamat.2005.01.017

S. Graça, R. Colaço, R. Vilar, Indentation size effect in nickel and cobalt laser clad coatings. Surf. Coat. Technol. 202, 538–548 (2007). https://doi.org/10.1016/j.surfcoat.2007.06.031

D. Olasz, G. Sáfrán, N. Szász, G. Huhn, N.Q. Chinh, Indentation size effect in exceptionally hard AlCu thin films. Mater. Lett. 330, 133409 (2023). https://doi.org/10.1016/j.matlet.2022.133409

M. Shell De Guzman, G. Neubauer, P. Flinn, W.D. Nix, The role of indentation depth on the measured hardness of materials. MRS Proc. 308, 613 (1993). https://doi.org/10.1557/PROC-308-613

N.A. Fleck, G.M. Muller, M.F. Ashby, J.W. Hutchinson, Strain gradient plasticity: theory and experiment. Acta Metall. Mater. 42, 475–487 (1994). https://doi.org/10.1016/0956-7151(94)90502-9

W.D. Nix, H. Gao, Indentation size effects in crystalline materials: A law for strain gradient plasticity. J. Mech. Phys. Solids 46, 411–425 (1998). https://doi.org/10.1016/S0022-5096(97)00086-0

A. Kumaraswamy, V.V. Rao, Effect of temperature on constraint factor of IN718 under static indentation conditions. Mater. Sci. Eng. A 527, 6230–6234 (2010). https://doi.org/10.1016/j.msea.2010.06.034

Y. Xu, D. Dini, Capturing the hardness of coating systems across the scales. Surf. Coat. Technol. 394, 125860 (2020). https://doi.org/10.1016/j.surfcoat.2020.125860

V.S. Kathavate, B. Praveen Kumar, I. Singh, K. Eswar Prasad, Analysis of indentation size effect (ISE) in nanoindentation hardness in polycrystalline PMN-PT piezoceramics with different domain configurations. Ceram. Int. 47, 11870–11877 (2021). https://doi.org/10.1016/j.ceramint.2021.01.027

S.J. Bull, Size effects in the mechanical response of nanoscale multilayer coatings on glass. Thin Solid Films 571, 290–295 (2014). https://doi.org/10.1016/j.tsf.2014.04.014

V. Vitry, J. Hastir, A. Mégret, S. Yazdani, M. Yunacti, L. Bonin, Recent advances in electroless nickel-boron coatings. Surf. Coat. Technol. 429, 127937 (2022). https://doi.org/10.1016/j.surfcoat.2021.127937

H. Algul, M. Uysal, A. Alp, A comparative study on morphological, mechanical and tribological properties of electroless NiP, NiB and NiBP coatings. Appl. Surf. Sci. Adv. 4, 100089 (2021). https://doi.org/10.1016/j.apsadv.2021.100089

D. Gültekin, E. Duru, H. Akbulut, Improved wear behaviors of lead-free electroless Ni B and Ni-B/CeO2 composite coatings. Surf. Coat. Technol. 422, 127525 (2021). https://doi.org/10.1016/j.surfcoat.2021.127525

A. Soni, A. Kumaraswamy, B. Praveen Kumar, Microstructural and tribomechanical characterization of NiB coated 4150 steel. J. Mater. Eng. Perform. (2024). https://doi.org/10.1007/s11665-023-09068-w

V. Vitry, A.-F. Kanta, J. Dille, F. Delaunois, Structural state of electroless nickel–boron deposits (5wt% B): characterization by XRD and TEM. Surf. Coat. Technol. 206, 3444–3449 (2012). https://doi.org/10.1016/j.surfcoat.2012.02.003

H. Seekala, L. Bathini, N.P. Wasekar, H. Krishnaswamy, P. Sudharshan Phani, A unified approach to quantify the material and geometrical effects in indentation size effect. J. Mater. Res. 38, 1740–1755 (2023). https://doi.org/10.1557/s43578-023-00927-9

X. Hernot, C. Moussa, O. Bartier, Study of the concept of representative strain and constraint factor introduced by Vickers indentation. Mech. Mater. 68, 1–14 (2014). https://doi.org/10.1016/j.mechmat.2013.07.004

C.-M. Sanchez-Camargo, A. Hor, C. Mabru, A robust inverse analysis method for elastoplastic behavior identification using the true geometry modeling of Berkovich indenter. Int. J. Mech. Sci. 171, 105370 (2020). https://doi.org/10.1016/j.ijmecsci.2019.105370

B. Merle, W.H. Higgins, G.M. Pharr, Extending the range of constant strain rate nanoindentation testing. J. Mater. Res. 35, 343–352 (2020). https://doi.org/10.1557/jmr.2019.408

P. Sudharshan Phani, W.C. Oliver, G.M. Pharr, Measurement of hardness and elastic modulus by load and depth sensing indentation: improvements to the technique based on continuous stiffness measurement. J. Mater. Res. 36, 2137–2153 (2021). https://doi.org/10.1557/s43578-021-00131-7

X. Zhang, C. Zhang, Inconsistent nanoindentation test hardness using different Berkovich indenters. J. Market. Res. 25, 6198–6208 (2023). https://doi.org/10.1016/j.jmrt.2023.07.063

B.L. Hackett, P. Sudharshan Phani, C.C. Walker, W.C. Oliver, G.M. Pharr, Advances in the measurement of hardness at high strain rates by nanoindentation. J. Mater. Res. 38, 1163–1177 (2023). https://doi.org/10.1557/s43578-023-00921-1

S.J. Bull, Microstructure and indentation response of TiN coatings: the effect of measurement method. Thin Solid Films 688, 137452 (2019). https://doi.org/10.1016/j.tsf.2019.137452

Y. Shelef, B. Bar-On, Size effects on the dynamic indentation modulus of films. Mech. Mater. 164, 104118 (2022). https://doi.org/10.1016/j.mechmat.2021.104118

O. Franke, J.C. Trenkle, C.A. Schuh, Temperature dependence of the indentation size effect. J. Mater. Res. 25, 1225–1229 (2010). https://doi.org/10.1557/JMR.2010.0159

Acknowledgments

The authors express their gratitude to the Director of ARDE and the Vice Chancellor of DIAT (DU) Pune, India, for granting permission to utilize the experimental facilities.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Contributions

Abhishek Soni: Conceptualization, theoretical analysis, sample preparation, experimentation, data analysis, first draft preparation. A. Kumaraswamy and Praveen Kumar B.: Conceptualization, sample preparation, review & editing of first draft, supervision. Nitin P. Wasekar and Krishna Valleti: Experimentation, data collection, review & editing of first draft.

Corresponding authors

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Soni, A., Kumaraswamy, A., Praveen Kumar, B. et al. Indentation size effects in hardness of annealed NiB coatings. MRS Communications (2024). https://doi.org/10.1557/s43579-024-00560-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1557/s43579-024-00560-5