Abstract

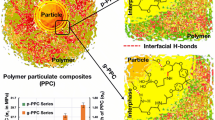

In this work, we investigate additively manufactured composites with populations of coarse and fine glass microspheres that are functionalized using silane coupling agents to explore how and why different functionalization of the fine and coarse fractions leads to vastly different mechanics. Combining strong interfaces on fine particles with weak interfaces on coarse particles leads to enhancements in elongation to break and toughness, whereas combining two types of strong interfaces leads to enhancement in elongation to break and reduction or maintenance of other measured tensile properties. These results can inform future work in tailoring mechanics of highly filled additively manufactured composites.

Graphical Abstract

Similar content being viewed by others

Data availability

Data not included already in the manuscript and supporting information will be made available upon reasonable request to the corresponding author.

References

D.M. Shah, J. Morris, T.A. Plaisted, A.V. Amirkhizi, C.J. Hansen, Highly filled resins for DLP-based printing of low density, high modulus materials. Add. Manuf. 37, 101736 (2021)

J. Morris, W. Wang, D. Shah, T. Plaisted, C.J. Hansen, A.V. Amirkhizi, Expanding the design space and optimizing stop bands for mechanical metamaterials. Mater. Des. 216, 110510 (2022)

Y. Wang, A. Delarue, I.M. McAninch, C.J. Hansen, E.J. Robinette, A.M. Peterson, Digital light processing of highly-filled polymer composites with interface-mediated mechanical properties. ACS Appl. Polym. Mater. 4, 6477–6486 (2022)

Y. Wang, I.M. McAninch, A.P. Delarue, C.J. Hansen, E.J. Robinette, A.M. Peterson, Additively manufactured thermosetting elastomer composites: Small changes in resin formulation lead to large changes in mechanical and viscoelastic properties. Mater. Adv. 4, 607–615 (2023)

T. Zheng, W. Wang, J. Sun, J. Liu, J. Bai, Development and evaluation of Al2O3–ZrO2 composite processed by digital light 3D printing. Ceram. Int. 46(7), 8682–8688 (2020)

K. Zhang, C. Xie, G. Wang, R. He, G. Ding, M. Wang, D. Dai, D. Fang, High solid loading, low viscosity photosensitive Al2O3 slurry for stereolithography based additive manufacturing. Ceram. Int. 45(1), 203–208 (2019)

W. Wang, J. Sun, B. Guo, X. Chen, K.P. Ananth, J. Bai, Fabrication of piezoelectric nano-ceramics via stereolithography of low viscous and non-aqueous suspensions. J. Eur. Ceram. Soc. 40(3), 682–688 (2020)

R.-J. Huang, Q.-G. Jiang, H.-D. Wu, Y.-H. Li, W.-Y. Liu, X.-X. Lu, S.-H. Wu, Fabrication of complex shaped ceramic parts with surface-oxidized Si3N4 powder via digital light processing based stereolithography method. Ceram. Int. 45(4), 5158–5162 (2019)

Y. Wei, D. Zhao, Q. Cao, J. Wang, Y. Wu, B. Yuan, X. Li, X. Chen, Y. Zhou, X. Yang, X. Zhu, C. Tu, X. Zhang, Stereolithography-based additive manufacturing of high-performance osteoinductive calcium phosphate ceramics by a digital light-processing system. ACS Biomater. Sci. Eng.Biomater. Sci. Eng. 6(3), 1787–1797 (2020)

Y.-H. Lee, J.-B. Lee, W.-Y. Maeng, Y.-H. Koh, H.-E. Kim, Photocurable ceramic slurry using solid camphor as novel diluent for conventional digital light processing (DLP) process. J. Eur. Ceram. Soc. 39(14), 4358–4365 (2019)

S.-L. Gao, E. Mader, Characterisation of interphase nanoscale property variations in glass fibre reinforced polypropylene and epoxy resin composites. Compos. A 33, 559–576 (2002)

L. Vaisman, G. Marom, H.D. Wagner, Dispersions of surface-modified carbon nanotubes in water-soluble and water-insoluble polymers. Adv. Func. Mater.Func. Mater. 16(3), 357–363 (2006)

L.M. Hamming, R. Qiao, P.B. Messersmith, L.C. Brinson, Effects of dispersion and interfacial modification on the macroscale properties of TiO(2) polymer matrix nanocomposites. Compos. Sci. Technol. 69(11–12), 1880–1886 (2009)

V.N. Mochalin, I. Neitzel, B.J.M. Etzold, A. Peterson, G. Palmese, Y. Gogotsi, Covalent incorporation of aminated nanodiamond into an epoxy polymer network. ACS Nano 5(9), 7494–7502 (2011)

L.S. Penn, F.A. Bystry, H.J. Marchionni, Relation of interfacial adhesion in Kevlar@/Epoxy systems to surface characterization and composite performance. Polym. Compos.. Compos. 4(1), 26–31 (1983)

J.J. Fallon, S.H. McKnight, M.J. Bortner, Highly loaded fiber filled polymers for material extrusion: a review of current understanding. Add. Manuf. 30, 100810 (2019)

I. Kim, S. Kim, A. Andreu, J.-H. Kim, Y.-J. Yoon, Influence of dispersant concentration toward enhancing printing precision and surface quality of vat photopolymerization 3D printed ceramics. Add. Manuf. 52, 102659 (2022)

A. Hodaei, O. Akhlaghi, N. Khani, T. Aytas, D. Sezer, B. Tatli, Y.Z. Menceloglu, B. Koc, O. Akbulut, Single additive enables 3d printing of highly loaded iron oxide suspensions. ACS Appl. Mater. Interfaces 10(11), 9873–9881 (2018)

A. Einstein, Eine neue Bestimmung der Moleküldimensionen. Ann. Phys. 324(2), 289–306 (2006)

H.M. Smallwood, Limiting law of the reinforcement of rubber. J. Appl. Phys. 15(11), 758–766 (1944)

E. Guth, Theory of filler reinforcement. Rubber Chem. Technol. 18(3), 596–604 (1945)

S. Wolff, J.-B. Donnet, Characterization of fillers in vulcanizates according to the einstein-guth-gold equation. Rubber Chem. Technol. 63(1), 32–45 (1990)

G. Heinrich, M. Klüppel, T.A. Vilgis, Reinforcement of elastomers. Curr. Opin. Solid State Mater. Sci.. Opin. Solid State Mater. Sci. 6(3), 195–203 (2002)

R.L. McCullough, Generalized combining rules for predicting transport properties of composite materials. Compos. Sci. Technol. 22(1), 3–21 (1985)

S. McGee, R.L. McCullough, Combining rules for predicting the thermoelastic properties of particulate filled polymers, polymers, polyblends, and foams. Polym. Compos.. Compos. 2(4), 149–161 (2004)

H. Tan, C. Liu, Y. Huang, P. Geubelle, The cohesive law for the particle/matrix interfaces in high explosives. J. Mech. Phys. Solids 53(8), 1892–1917 (2005)

L. Brassart, H.M. Inglis, L. Delannay, I. Doghri, P.H. Geubelle, An extended Mori-Tanaka homogenization scheme for finite strain modeling of debonding in particle-reinforced elastomers. Comput. Mater. Sci.. Mater. Sci. 45(3), 611–616 (2009)

A.P. Delarue, I.M. McAninch, A.M. Peterson, C.J. Hansen, Increasing printable solid loading in digital light processing using a bimodal particle size distribution. 3D Print. Add. Manuf. (2023). https://doi.org/10.1089/3dp.2022.0305

Y. Wang, C.J. Hansen, C.-C. Wu, E.J. Robinette, A.M. Peterson, Effect of surface wettability on the interfacial adhesion of a thermosetting elastomer on glass. RSC Adv. 11(49), 31142–31151 (2021)

B.D. Mather, K. Viswanathan, K.M. Miller, T.E. Long, Michael addition reactions in macromolecular design for emerging technologies. Prog. Polym. Sci.. Polym. Sci. 31(5), 487–531 (2006)

Jensen, R. E.; Palmese, G. R.; McKnight, S. H. Dynamic Mechanical Analysis of E-Beam and Thermally Curable IPN Thermosets; 2002.

S.-C. Kwon, T. Adachi, W. Araki, A. Yamaji, Effect of composing particles of two sizes on mechanical properties of spherical silica-particulate-reinforced epoxy composites. Compos. B Eng. 39(4), 740–746 (2008)

P. Dittanet, R.A. Pearson, Effect of bimodal particle size distributions on the toughening mechanisms in silica nanoparticle filled epoxy resin. Polymer 54(7), 1832–1845 (2013)

P.J. Rae, H.T. Goldrein, S.J.P. Palmer, J.E. Field, A.L. Lewis, Quasi-static studies of the deformation and failure of β-HMX based polymer bonded explosives. Proc. R. Soc. A 2002(458), 743–762 (2019)

A. Mujtaba, M. Keller, S. Ilisch, H.J. Radusch, T. Thurn-Albrecht, K. Saalwächter, M. Beiner, Mechanical properties and cross-link density of styrene-butadiene model composites containing fillers with bimodal particle size distribution. Macromolecules 45(16), 6504–6515 (2012)

J. Ramier, L. Chazeau, C. Gauthier, L. Guy, M.N. Bouchereau, Influence of silica and its different surface treatments on the vulcanization process of silica filled SBR. Rubber Chem. Technol. 80(1), 183–193 (2007)

Acknowledgments

This research was sponsored by DEVCOM Army Research Laboratory and was accomplished under Cooperative Agreement Number W911NF-19-2-0100. The views and conclusions contained in this document are those of the authors and should not be interpreted as representing the official policies, either expressed or implied, of DEVCOM ARL or the U.S. Government. The U.S. Government is authorized to reproduce and distribute reprints for Government purposes notwithstanding any copyright notation herein. The team is grateful to Mr. John Vericella and Autodesk for the donation of the Ember printers used in this work.

Funding

This research was sponsored by DEVCOM Army Research Laboratory and was accomplished under Cooperative Agreement Number W911NF-19–2-0100.

Author information

Authors and Affiliations

Contributions

Tahamina Nasrin: conceptualization, data curation, formal analysis, investigation, methodology, writing – original draft preparation; Ahmed Adisa: investigation, methodology, writing—review & editing; Christopher Hansen: conceptualization, funding acquisition, resources, writing – review & editing; Farhad Pourkamali-Anaraki: conceptualization, funding acquisition, writing – review & editing; Robert Jensen: conceptualization, writing – review & editing; Amy Peterson: conceptualization, methodology, project administration, resources, supervision, writing – original draft preparation.

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Nasrin, T., Adisa, A.O., Hansen, C.J. et al. Emergent mechanical properties in highly filled additively manufactured polymer composites. MRS Communications (2024). https://doi.org/10.1557/s43579-024-00530-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1557/s43579-024-00530-x