Abstract

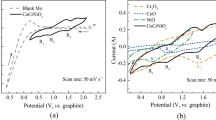

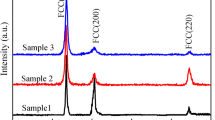

Investigating the mechanical properties of nanoceramic has been an important topic in fundamental science and industrial application. In this study, pressure gradient approach method is introduced. The yield strength of nano-CeO2 increases with decreasing grain sizes and increasing pressure, consistent with the Hall-Patch effect. Three cycle experiments show that the decrease in yield stress after cycling is correlated with the decrease in sample thickness. For comparison, the yield strength of 10 nm nickel was also measured. Transmission electron microscope measurement revealed the quenched the deformation of coarse-grained CeO2 is dominated by cracks, while small amount of dislocations exist in CeO2.

Graphical Abstract

Similar content being viewed by others

Data availability

Data sets generated during the current study are available from the corresponding author on reasonable request. And all data can be shared openly.

References

L. Mishnaevsky, K. Branner, H. Nørgaard Petersen, J. Beauson, M. McGugan, B.F. Sørensen, Materials for wind turbine blades: an overview. Materials 10(11), 1285 (2017). https://doi.org/10.3390/ma10111285

X. Shen, J. Lian, Z. Jiang, Q. Jiang, High strength and high ductility of electrodeposited nanocrystalline Ni with a broad grain size distribution. Mater. Sci. Eng., A 487(1–2), 410–416 (2008). https://doi.org/10.1016/j.msea.2007.10.018

G.J. Fan, H. Choo, P.K. Liaw, E.J. Lavernia, Plastic deformation and fracture of ultrafine-grained Al–Mg alloys with a bimodal grain size distribution. Acta Mater. 54(7), 1759–1766 (2006). https://doi.org/10.1016/j.actamat.2005.11.044

C. Bin, Exploring nanomechanics with high-pressure techniques. Matter Radiat. Extrem. 5(6), 068104 (2020). https://doi.org/10.1063/5.0032600

V.I. Levitas, M. Javanbakht, Phase transformations in nanograin materials under high pressure and plastic shear: nanoscale mechanisms. Nanoscale 6(1), 162–166 (2014). https://doi.org/10.1039/c3nr05044k

X. Zhou, Z. Feng, L. Zhu, Xu. Jianing, L. Miyagi, H. Dong, H. Sheng, Y. Wang, Q. Li, Y. Ma, H. Zhang, J. Yan, N. Tamura, M. Kunz, K. Lutker, T. Huang, D.A. Hughes, X. Huang, B. Chen, High-pressure strengthening in ultrafine-grained metals. Nature 579(7797), 67–72 (2020). https://doi.org/10.1038/s41586-020-2036-z

H. Duanwei, T.S. Duffy, X-ray diffraction study of the static strength of tungsten to 69 GPa. Phys. Rev. B 73(13), 4106 (2006). https://doi.org/10.1103/physrevb.73.134106

J. Qian, C. Pantea, J. Zhang, L.L. Daemen, Y. Wang, Yield strength of α-silicon nitride at high pressure and high temperature. J. Am. Ceram. Soc. (2005). https://doi.org/10.1111/j.1551-2916.2005.00163.x

H. Zhang, H. Xiao, Z. Zhang, P. Zhang, Y. Li, Y. Ma, Y. Kuang, Y. Zhao, Z. Chai, Nano-CeO2 exhibits adverse effects at environmental relevant concentrations. Environ. Sci. Technol. 45(8), 3725–3730 (2011). https://doi.org/10.1021/es103309n

L. Shuna, Z. Huaqing, Q. Zhangfeng, Morphologic effects of nano CeO2–TiO2 on the performance of Au/CeO2–TiO2 catalysts in low-temperature CO oxidation. Appl. Catal. B Environ. 144, 498–506 (2014). https://doi.org/10.1016/j.apcatb.2013.07.049

M. Li, S. Zhang, H. Li, Y. He, J.H. Yoon, T.Y. Cho, Effect of nano-CeO2 on cobalt-based alloy laser coatings. J. Mater. Process. Technol. 202(1–3), 107–111 (2008). https://doi.org/10.1016/j.jmatprotec.2007.08.050

A. Pmk, B. Km, A comprehensive study on thermal storage characteristics of nano-CeO2 embedded phase change material and its influence on the performance of evacuated tube solar water heater. Renew. Energy 162, 662–676 (2020). https://doi.org/10.1016/j.renene.2020.08.122

Y. Shen, P.K. Sahoo, Y. Pan, A study of nanocomposite coatings on the surface of ship exhaust pipe. Surf. Rev. Lett. 24(08), 1750112 (2017). https://doi.org/10.1142/S0218625X17501128

M. Srivastava, V.K.W. Grips, K.S. Rajam, Electrodeposition of Ni–Co composites containing nano-CeO2 and their structure, properties. Appl. Surf. Sci. 257(3), 717–722 (2010). https://doi.org/10.1016/j.apsusc.2010.07.046

T. Montini, M. Melchionna, M. Monai, P. Fornasiero, Fundamentals and catalytic applications of CeO2-based materials. Chem. Rev. (2016). https://doi.org/10.1021/acs.chemrev.5b00603

Y. Zhang, S. Zhao, J. Feng, S. Song, W. Shi, D. Wang, H. Zhang, Unraveling the physical chemistry and materials science of CeO2’-based nanostructures. Chem. 7(8), 2022–2059 (2021). https://doi.org/10.1016/j.chempr.2021.02.015

Q. Jing, B. Yan, W. Qiang, F. Jing, J. Sheng, Yield strength of molybdenum at high pressures. Rev. Sci. Instrum. 78(7), 073906 (2007). https://doi.org/10.1063/1.2758549

C. Meade, R. Jeanloz, Yield strength of MgO to 40 GPa. J. Geophys. Res. Solid Earth 93(B4), 3261–3269 (1988). https://doi.org/10.1029/jb093ib04p03261

C. Meade, R. Jeanloz, Yield strength of Al 2 O 3 at high pressures. Phys. Rev. B 42(4), 2532 (1990). https://doi.org/10.1103/PhysRevB.42.2532

W. Yang, X. Huang, R. Harder, J.N. Clark, I.K. Robinson, H.K. Mao, Coherent diffraction imaging of nanoscale strain evolution in a single crystal under high pressure. Nat. Commun. 4(1), 1680 (2013). https://doi.org/10.1038/ncomms2661

Y. Shen, R.S. Kumar, M. Pravica, M.F. Nicol, Characteristics of silicone fluid as a pressure transmitting medium in diamond anvil cells. Rev. Sci. Instrum. 75(11), 4450–4454 (2004). https://doi.org/10.1063/1.1786355

A. Dewaele, G. Fiquet, P. Gillet, Temperature and pressure distribution in the laser-heated diamond–anvil cell. Rev. Sci. Instrum. 69(6), 2421–2426 (1998). https://doi.org/10.1063/1.1148970

Z.C. Cordero, B.E. Knight, C.A. Schuh, Six decades of the Hall-Petch effect—a survey of grain-size strengthening studies on pure metals. Int. Mater. Rev. 61(8), 1–18 (2016). https://doi.org/10.1080/09506608.2016.1191808

J.J. Brown, A.I. Baca, K.A. Bertness, D.A. Dikin, R.S. Ruoff, V.M. Bright, Tensile measurement of single crystal gallium nitride nanowires on MEMS test stages. Sens. Actuators, A 166(2), 177–186 (2011). https://doi.org/10.1016/j.sna.2010.04.002

A. Schweiger, I. Zimmermann, A new approach for the measurement of the tensile strength of powders. Powder Technol. 101(1), 7–15 (1999). https://doi.org/10.1016/S0032-5910(98)00117-X

R. Berenbaum, I. Brodie, Measurement of the tensile strength of brittle materials. Br. J. Appl. Phys 10(6), 281 (1959). https://doi.org/10.1088/0508-3443/10/6/307

A. Navarro, E.R. de Los Rios, An alternative model of the blocking of dislocations at grain boundaries. Philos. Mag. A 57(1), 37–42 (1988). https://doi.org/10.1080/01418618808204497

T.B. Britton, A.J. Wilkinson, Stress fields and geometrically necessary dislocation density distributions near the head of a blocked slip band. Acta Mater. 60(16), 5773–5782 (2012). https://doi.org/10.1016/j.actamat.2012.07.004

Acknowledgments

This work was supported by Center for High Pressure Science and Technology Advanced Research (HPSTAR).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no confict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, H., Yuan, M., Li, H. et al. The mechanical properties of nanoceramic CeO2 under high pressure. MRS Communications 13, 1125–1130 (2023). https://doi.org/10.1557/s43579-023-00401-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43579-023-00401-x