Abstract

Energy-absorbing materials are widely used as protection for crash mitigation and concussive head impacts reduction. A structural design can significantly enhance energy absorption in different ways, including plastic deformation and bi-stability. Here, 3D-printed energy-absorbing cells of open and capped double frustum structures are characterized via finite element simulations and compressive experiments. The designs demonstrated a buckling instability under compression, achieving 47 times higher specific energy absorption at their critical stress compared with a solid material. For capped structures, strain rate effect on critical stresses is due to air frictional dissipation. The open structures showed beneficial energy hysteresis due to suction in the cyclic tests.

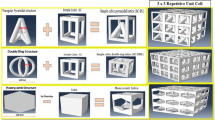

Graphical abstract

Similar content being viewed by others

Data availability

Data will be made available on reasonable request. The online version contains supplementary information available.

References

J.A. Langlois, W. Rutland-Brown, M.M. Wald, J. Head Trauma Rehabil. 21, 375–378 (2006)

P.J.A. Dean, A. Sterr, Front. Hum. Neurosci. (2013). https://doi.org/10.3389/fnhum.2013.00030

C. Konrad, A.J. Geburek, F. Rist, H. Blumenroth, B. Fischer, I. Husstedt, V. Arolt, H. Schiffbauer, H. Lohmann, Psychol. Med. 41, 1197–1211 (2011)

T.D. Stein, V.E. Alvarez, A.C. McKee, Curr. Pain Headache Rep. 19, 47 (2015)

L. Mainwaring, K.M. Ferdinand Pennock, S. Mylabathula, B.Z. Alavie, Int. J. Psychophysiol. 132, 39–54 (2018)

J.J. Andrew, H. Alhashmi, A. Schiffer, S. Kumar, V.S. Deshpande, Mater. Des. 208, 109863 (2021)

G. Li, S. Ferdousi, G. Tejeda-Godinez, Y. Jiang, MRS Commun. 12, 982–987 (2022)

P.K. Archakam, S. Muthuswamy, J. Vib. Eng. Technol. 9, 1635–1656 (2021)

F. Tarlochan, Materials (Basel). (2021). https://doi.org/10.3390/ma14164731

A. Riccio, M. Madonna, C. Palumbo, A. Sellitto, Heliyon. 8, e11695 (2022)

X. Yang, J. Ma, D. Wen, J. Yang, Prog. Aerosp. Sci. 114, 100618 (2020)

S. Shukla, B.K. Behera, Compos. Struct. 290, 115530 (2022)

S. Shan, S.H. Kang, J.R. Raney, P. Wang, L. Fang, F. Candido, J.A. Lewis, K. Bertoldi, Adv. Mater. 27, 4296–4301 (2015)

Y. Cao, M. Derakhshani, Y. Fang, G. Huang, C. Cao, Adv. Funct. Mater. 31, 1–23 (2021)

C. Winkelmann, S.S. Kim, V. La Saponara, Compos. Struct. 93, 171–178 (2010)

A. Montalbano, G.M. Fadel, G. Li, Mech. Based Des. Struct. Mach. 51, 1368–1386 (2020)

J. Li, Y. Yang, H. Jiang, Y. Wang, Y. Chen, S. Jiang, J.M. Wu, G. Zhang, Compos. Part B Eng. 232, 109617 (2022)

S.D. Papka, S. Kyriakides, J. Mech. Phys. Solids. 42, 1499–1532 (1994)

H.G. Tattersall, G. Tappin, J. Mater. Sci. 1, 296–301 (1966)

J. Li, Z. Zhu, L. Fang, S. Guo, U. Erturun, Z. Zhu, J.E. West, S. Ghosh, S.H. Kang, Nanoscale 9, 14215–14228 (2017)

A.B.M. Supian, S.M. Sapuan, M.Y.M. Zuhri, E.S. Zainudin, H.H. Ya, Def. Technol. 14, 291–305 (2018)

M. Bodaghi, A. Serjouei, A. Zolfagharian, M. Fotouhi, H. Rahman, D. Durand, Int. J. Mech. Sci. 173, 105451 (2020)

Y. Wu, J. Fang, C. Wu, C. Li, G. Sun, Q. Li, Int. J. Mech. Sci. 246, 108102 (2023)

F. Rahimidehgolan, W. Altenhof, Compos. Part B Eng. 253, 110513 (2023)

C. Rodrigo, S. Xu, Y. Durandet, D. Fraser, D. Ruan, Eng. Struct. 284, 115909 (2023)

M.N. Islam, Y. Jiang, ACS Sustain. Chem. Eng. 10, 7818–7824 (2022)

G. Belingardi, R. Montanini, M. Avalle, Int. J. Impact Eng. 25, 455–472 (2001)

L. Sun, R.F. Gibson, F. Gordaninejad, J. Suhr, Compos. Sci. Technol. 69, 2392–2409 (2009)

F. Xu, X. Zhang, H. Zhang, Eng. Struct. 171, 309–325 (2018)

Y. Jiang, J.L. Hor, D. Lee, K.T. Turner, ACS Appl. Mater. Interfaces. 10, 44011–44017 (2018)

L. Lamb, T.B. Hoshizaki, Proc. Inst. Mech. Eng. Part H J. Eng. Med. 223, 1021–1031 (2009)

L. Lamb, A. Post, T.B. Hoshizaki, J. ASTM Int. (2009). https://doi.org/10.1520/JAI101884

T.B. Hoshizaki, A. Post, J. ASTM Int. (2009). https://doi.org/10.1520/JAI101883

G. Gimbel, T.B. Hoshizaki, Proceedings of the Fifth International Symposium on Safety in Ice Hockey, Denver, Colorado, USA (Sage, California, 2008)

T. Frenzel, C. Findeisen, M. Kadic, P. Gumbsch, M. Wegener, Adv. Mater. 28, 5865–5870 (2016)

Y. Jiang, L.M. Korpas, J.R. Raney, Nat. Commun. 10, 128 (2019)

Acknowledgments

The authors acknowledge the support from the Vehicle Technologies Office (VTO) in the Department of Energy (DOE), award number: Award VTO CPS 36928. S.Z. acknowledges the supports from University of North Texas Undergraduate Research Fellowship (URF) from Honors College. Y.J. acknowledges the Ralph E. Powe Junior Faculty Enhancement Awards from Oak Ridge Associated Universities (ORAU).

Funding

Funding was provided by Vehicle Technologies Office (Grant No. VTO CPS 36928),[University of North Texas (Grant No. Undergraduate Research Fellowship), and Oak Ridge Associated Universities (Grant No. Ralph E. Powe Junior Faculty Enhancement Awards)].

Author information

Authors and Affiliations

Contributions

YJ performed the conception and design of this paper. SF organized the manuscript and performed impact tests. SZ performed numerical simulations and experiments. All authors contributed to the manuscript writing and revision. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Supplementary file1 (MP4 1611 kb)

Supplementary file2 (MP4 2530 kb)

Supplementary file3 (MP4 2907 kb)

Supplementary file4 (MP4 1318 kb)

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ferdousi, S., Zoch, S. & Jiang, Y. 3D-printed energy-absorbing structures using instability and air frictional and suction dissipation. MRS Communications 13, 1025–1030 (2023). https://doi.org/10.1557/s43579-023-00383-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43579-023-00383-w